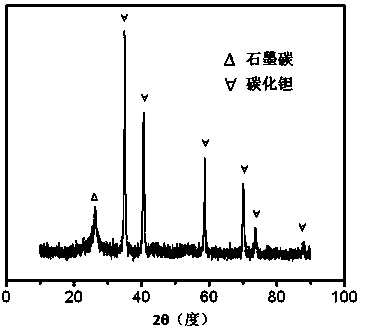

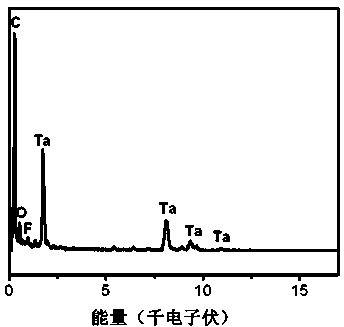

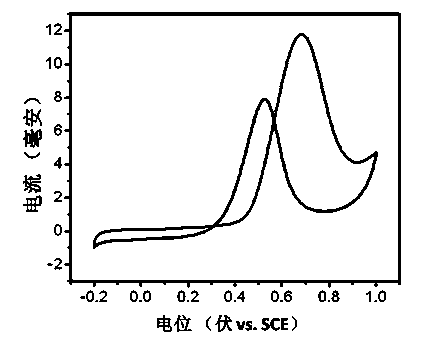

Fluorine-doped nano-tantalum carbide/graphitized carbon composite material and preparation method thereof

A technology of nano-tantalum carbide and graphitized carbon, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems that tantalum pentachloride is prone to hydrolysis and is not suitable for synthesizing precursors, etc., to alleviate the energy crisis, Easy to achieve large-scale production and abundant raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035](1) Soak the macroporous basic acrylic anion resin with 1 mol / L hydrochloric acid for 10 hours, then wash it with deionized water, and mix it with 1 mol / L sodium hypochlorite and 1 mol / L sodium hydroxide (2) Dissolve 0.82 g of sodium hexanitrocobaltate in 1000 mL of deionized water, then add 10 g of the treated macroporous basic acrylic anion resin, and stir magnetically for 6 hours, the metal ion exchanged resin was obtained; (3) the metal ion exchanged resin in step (2) was washed with deionized water, filtered, and dried; (4) the resin in step (3) was mixed with 0.39 g fluorine Potassium tantalate was added to 1000 mL deionized water together, and stirred for 2 hours; (5) The resin exchanged with metal ions in step (4) was washed with deionized water, filtered, and dried; (6) The resin in step (5) was dried A good resin was heated in a tube furnace at a rate of 5 °C / min to 1100 °C for 1 hour with a nitrogen flow rate of 20 mL / min. (7) After the heat-treated sample wa...

Embodiment 2

[0037] (1) Soak the macroporous basic acrylic anion resin with 1 mol / L hydrochloric acid for 10 hours, then wash it with deionized water, and mix it with 1 mol / L sodium hypochlorite and 1 mol / L sodium hydroxide (2) Dissolve 0.84 g of potassium ferrocyanide in 100 mL of deionized water, then add 10 g of the treated macroporous basic acrylic anion resin, and stir magnetically for 6 hours; (3) Wash the resin exchanged with metal ions in step (2) with deionized water, filter, and dry; (4) add the resin in step (3) together with 0.39 g of potassium fluorotantalate into 1000 mL of deionized water , heated to boiling, and stirred for 2 hours; (5) Wash the resin exchanged with metal ions in step (4) with deionized water, filter, and dry; (6) Dry the resin in step (5) in a tube furnace The heating rate was increased to 1100 °C at a rate of 10 °C / min, and the heat treatment was carried out for 1 hour with a nitrogen flow rate of 20 mL / min. (7) After the heat-treated sample was ball mil...

Embodiment 3

[0039] (1) Soak the macroporous basic acrylic anion resin with 1 mol / L hydrochloric acid for 10 hours, then wash it with deionized water, and mix it with 1 mol / L sodium hypochlorite and 1 mol / L sodium hydroxide (2) Dissolve 4.12 g of sodium hexanitrocobaltate in 100 mL of deionized water, then add 10 g of the treated macroporous basic acrylic anion resin, and stir magnetically for 6 hours; (3) The resin exchanged with metal ions in step (2) was washed with deionized water, filtered, and dried; (4) The resin in step (3) was added to 100 mL together with 19.61 g of potassium fluorotantalate In deionized water, heat to boiling and stir for 2 hours; (5) wash, filter and dry the resin exchanged with metal ions in step (4) with deionized water; (6) dry the resin in step (5) in In a tube furnace, the temperature was raised to 1100 °C at a rate of 8 °C / min, and the heat treatment was performed for 1 hour, with a nitrogen flow rate of 20 mL / min. (7) After the heat-treated sample was b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com