Method for preparing potassium fluotantalate

A technology of potassium fluorotantalate and hydrofluoric acid, which is applied in the field of metallurgy, can solve the problems of high recovery process cost, high ammonia nitrogen content in the discharge, and large hydrofluoric acid consumption, so as to reduce production costs, reduce consumption, and eliminate pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

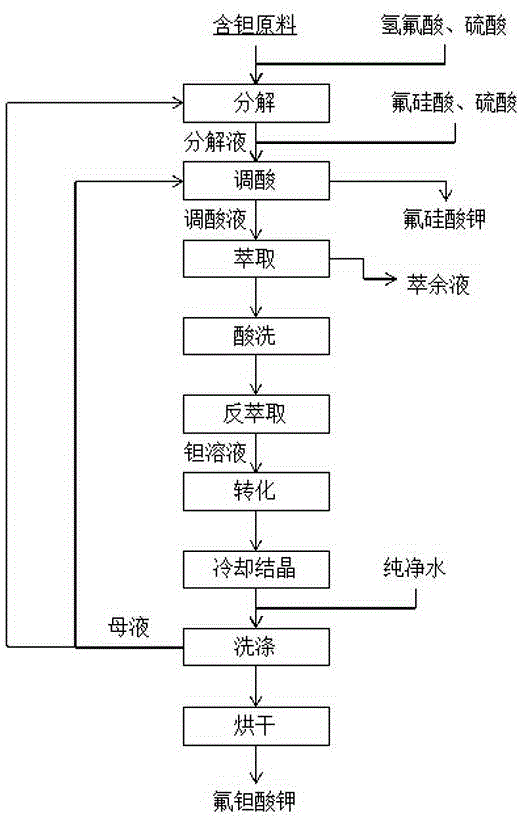

Method used

Image

Examples

Embodiment 1

[0028] (1) The raw material is tantalum capacitor waste with tantalum content: 80% (mass), and Nb less than 1%. The weight is 500 grams. Add 400 grams of hydrofluoric acid, 150 grams of sulfuric acid, and 500 grams of mother liquor. Stir in the decomposition tank and carry out After 8 hours of decomposition, 1.05L of decomposition solution was obtained;

[0029] (2) Add 3.1 kg of mother liquor, 0.21 kg of fluosilicic acid, and 0.10 kg of sulfuric acid to the decomposition liquid for low-acid preparation. The total acidity is 3.5 mol / L, and the sulfuric acid is 1 mol / L, and then filter out potassium fluorosilicate precipitation. Obtain 183.3 grams of industrial potassium fluorosilicate and acid adjusting solution;

[0030] (3) Perform 10-stage extraction of the acid-adjusting solution, the extraction agent is 2-octanol, 8-stage pickling, and 12-stage back extraction with deionized water to obtain 7.31L of tantalum solution;

[0031] (4) After heating the tantalum solution to 9...

Embodiment 2

[0035] The raw material is tantalum capacitor waste with tantalum content: 90%, Nb less than 1%, the weight is 500 grams, then add 750 grams of hydrofluoric acid, 400 grams of sulfuric acid, 1000 grams of mother liquor, stir, and decompose for 24 hours to obtain 2.15L of decomposition liquid Add 6 kg of mother liquor, 1.4 kg of fluosilicic acid, and 0.63 kg of sulfuric acid, and carry out low-acid deployment. The total acidity reaches 4.5 mol / L, and the sulfuric acid reaches 1.5 mol / L, and then filters out potassium fluosilicate precipitation to obtain industrial fluosilicate Potassium 210 grams and acid-adjusting solution; the acid-adjusting solution is subjected to 10-stage extraction, the extraction agent is 2-octanol, 8-stage pickling, and 12-stage back extraction with deionized water to obtain 8.1L of tantalum solution; after the tantalum solution is heated to 90°C , and then add reagent hydrofluoric acid 0.81L, potassium chloride 430 grams, carry out conversion, then wate...

Embodiment 3

[0037] The raw material is tantalum content: 10%, Nb is less than 1%, the by-product of preparing tantalum powder by sodium reduction after water washing, the weight is 1000 grams, then add 800 grams of hydrofluoric acid, 300 grams of sulfuric acid, 1000 grams of mother liquor, stir, carry out Decompose in 8 hours to obtain 2.1L of decomposition liquid; add 4.5 kg of mother liquor, 0.93 kg of fluosilicic acid, and 0.3 kg of sulfuric acid to make low-acid preparation, the total acidity reaches 3.5 mol / L, sulfuric acid reaches 1.1 mol / L, and then filters out fluosilicic acid Potassium precipitation to obtain 140 grams of industrial potassium fluorosilicate and acid-adjusting solution; the acid-adjusting solution was subjected to 10-stage extraction, the extractant was 2-octanol, 8-stage pickling, and 12-stage back extraction with deionized water to obtain tantalum solution 2.0L After the tantalum solution is heated to 90°C, add 0.1L of reagent hydrofluoric acid and 98 grams of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com