Treatment method for wastewater produced during tantalum-niobium hydrometallurgy

A technology of hydrometallurgy and wastewater treatment, which is applied in the field of metallurgy and can solve problems such as radioactive slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

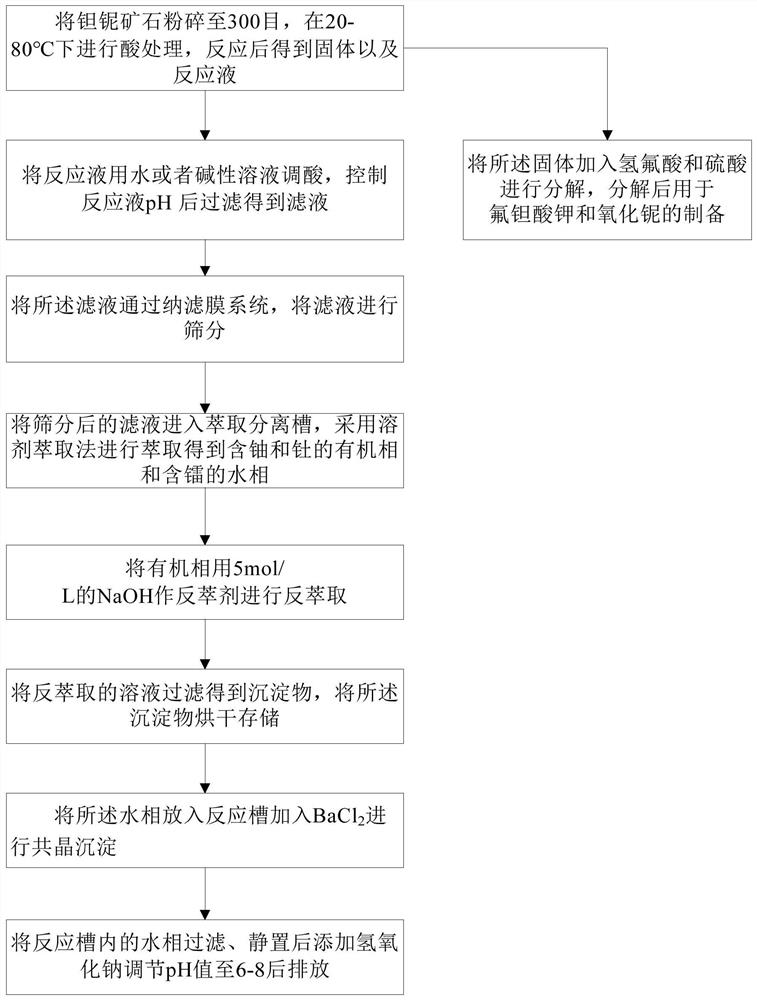

Method used

Image

Examples

Embodiment

[0058] 1. Pre-decomposition

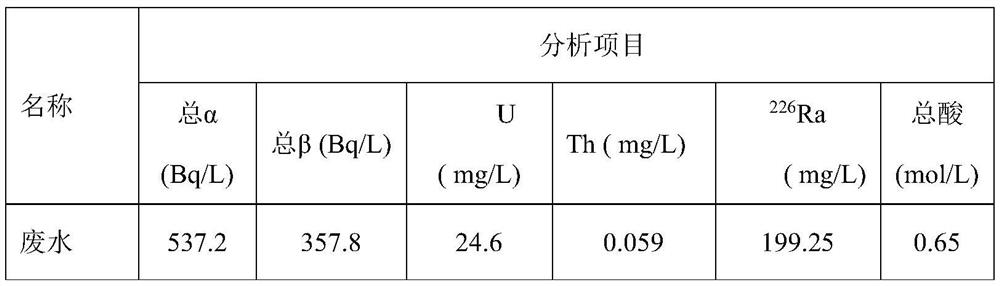

[0059] Crush the tantalum-niobium ore to 300 meshes, and then pre-decompose the ore and dilute sulfuric acid solution with an acidity of 10% according to the weight ratio of 1:2-1:3, and the decomposition temperature is below 80 degrees Celsius. The decomposition time is 24-48 hours. Finally, the acid solution is filtered to obtain a filter residue and a filtrate. The filtrate goes to the next step. The waste water composition in the solution that obtains is as follows:

[0060] The composition of radioactive wastewater is as follows (fluorine content 125 g / L)

[0061]

[0062] The wastewater produced by smelting tantalum and niobium minerals contains natural uranium, thorium and their daughters 226Ra, 228Ra and 224Ra, of which 226Ra and 224Ra are alpha emitters, and 228Ra is beta emitter.

[0063] 2. Adjust acidity

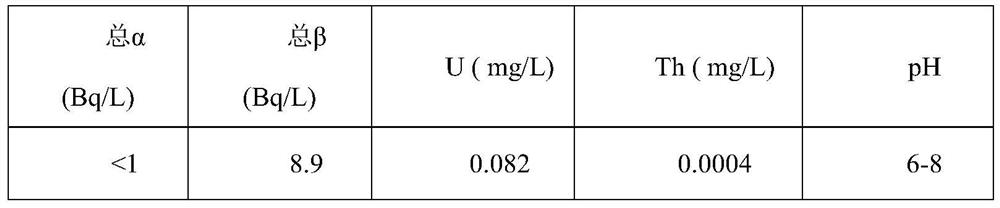

[0064] Add the filtrate from step 1 into the reaction tank, use 100 kg of prepared sodium hydroxide solution, stir and reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com