A system for pre-embedding electrical pipelines in a secondary structure and its implementation method

A secondary structure and pipeline technology, applied in the installation of electrical components, building components, cables, etc., can solve problems such as complicated construction steps, and achieve the effect of ensuring the fixing effect and facilitating installation and replacement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

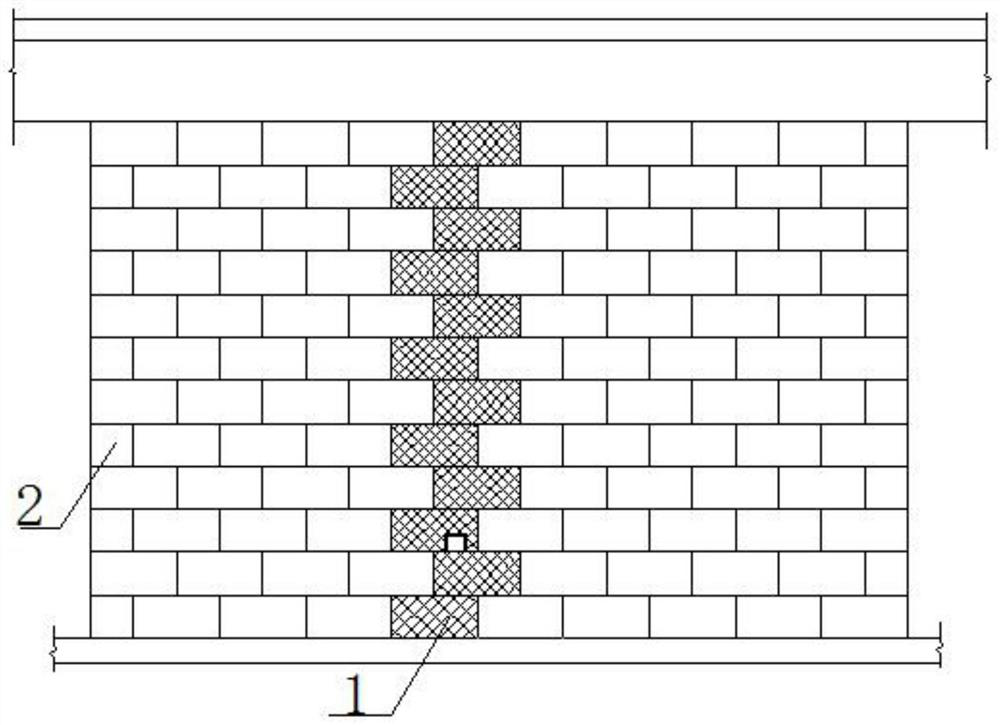

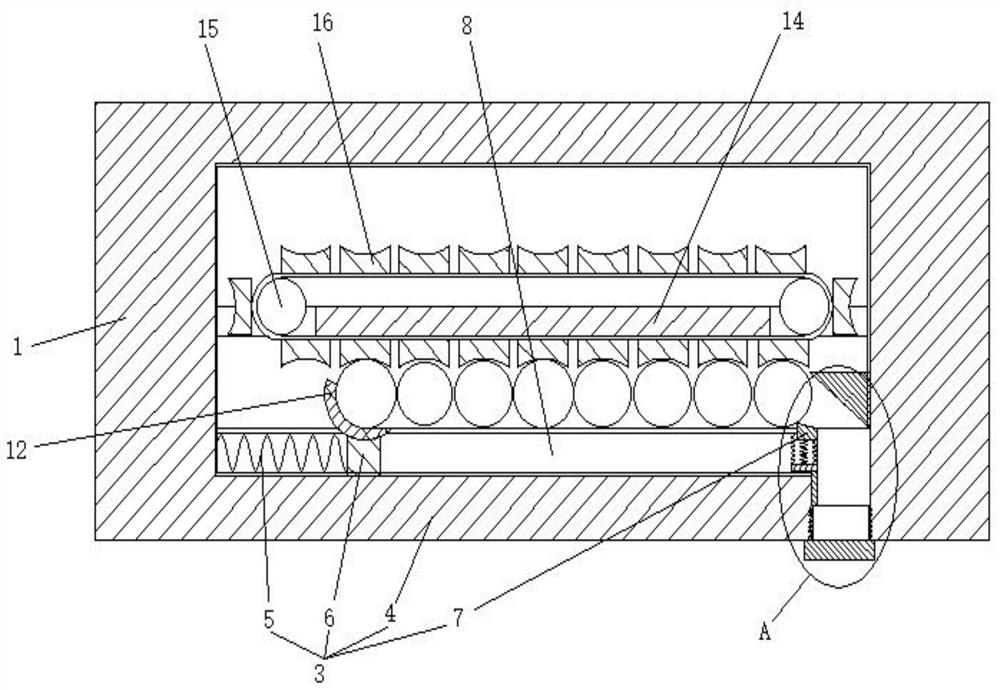

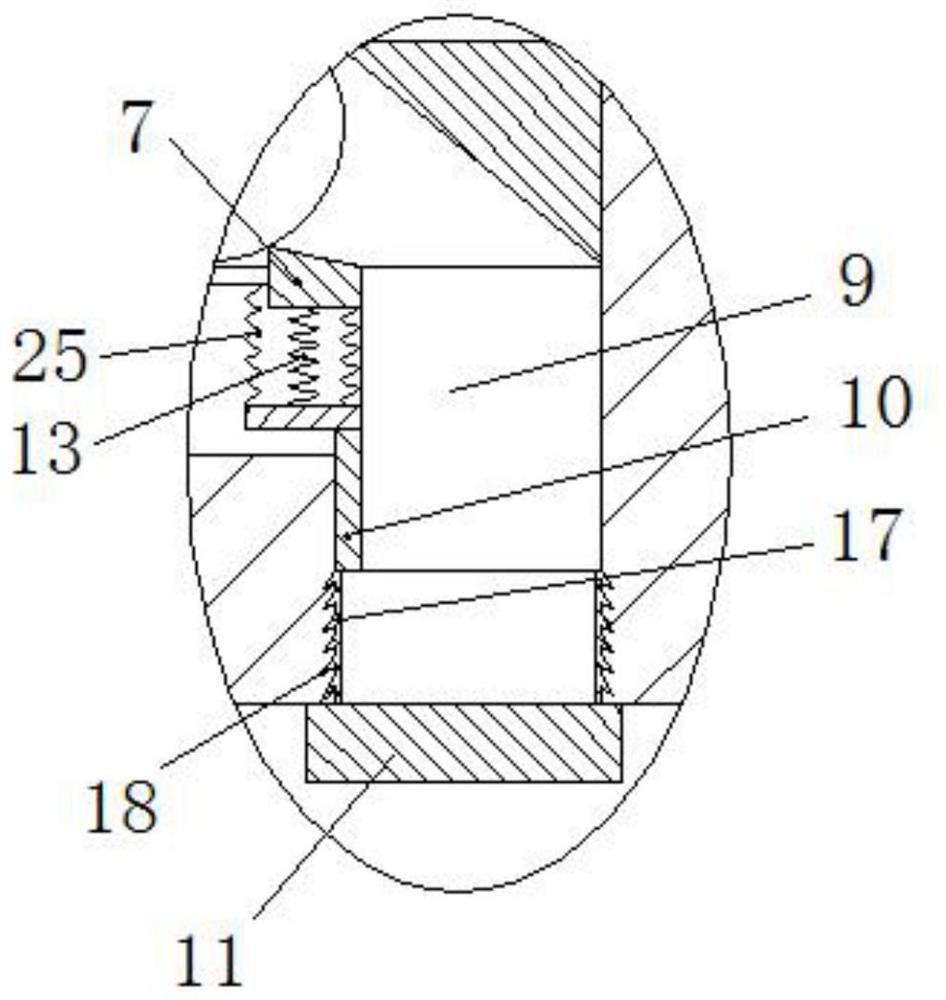

[0029] Such as Figure 1 to Figure 4 As shown, a pre-embedded electrical pipeline system in a secondary structure includes a prefabricated brick wall and a masonry wall 2. The prefabricated brick wall is stacked at the preset pipeline position by several prefabricated bricks 1 arranged in an orderly manner. In the masonry wall 2, a junction box is added to the bottom prefabricated brick 1 at the position of the preset pipeline, and a fixed line card connected to the junction box is embedded in each prefabricated brick 1 located directly above the junction box 3. The electric pipeline is directly fixed by connecting the fixed line card 3 with the junction box. The fixed line card 3 includes a housing 4, a first spring 5, a clip 6 and a wedge-shaped block 7, the housing 4 is a hollow structure with upper and lower notches, and the inner wall of the housing 4 is provided with a positioning structure and a guide groove 8 , where the positioning structure can limit the position of...

Embodiment 2

[0038] Such as Figure 1 to Figure 4 As shown, a method for implementing an electrical pipeline pre-embedded system in a secondary structure includes the following steps,

[0039] Step 1. First, stack the masonry wall 2 and reserve a suitable space at the preset pipeline position. Several orderly arranged prefabricated bricks 1 are stacked on the masonry wall 2 at the preset pipeline position. Inside, the cavity 22 of the first waterproof layer 21 on the stacking groove 19 is opposite to the cavity 22 of the first waterproof layer 21 on the stacking protrusion 20, and the first waterproof layer 21 on the stacking groove 19 The first waterproof layer 21 on the stacking protrusion 20 is in a compressed state after stacking, and it is ensured that all shells 4 are coaxial and all positioning structures are located on the same side;

[0040] Step 2. Finally, the electrical pipelines are laid in the prefabricated brick 1, and the cover plate 11 matching the housing 4 is put on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com