Building construction method of earth-covered oil tank, hoisting device and using method of hoisting device

The technology of a hoisting device and a construction method is applied in the directions of buildings, building types, building structures, etc., and can solve the problems of poor construction of the pouring formwork of concrete tanks, excessively large volume of steel storage tanks, and difficulty in tailoring welding of steel storage tanks. Achieve the effect of avoiding high-altitude work, improving efficiency and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A construction method of a soil-covered oil tank.

[0038] The construction method of the earth-covered oil tank of the present invention comprises the following steps:

[0039] a. On the ground of the construction area, dig a deep pit for construction operation and burying the soil-covered oil tank, and pour a concrete platform in the center of the bottom of the deep pit as the bottom of the concrete tank.

[0040] b. After the concrete platform is solidified, hoist the tailor-welded components for making the side wall and tank roof of the steel storage tank, and build up the pouring formwork for pouring the tank wall and tank roof of the concrete tank along the edge of the concrete platform, At the same time, pre-embed the steel skeleton in the pouring area of the built tank wall and roof, reserve a temporary entrance and exit at the lower part of the tank wall of the concrete tank, and then pour concrete into the pouring area. After the concrete solid...

Embodiment 2

[0048] Embodiment 2: A hoisting device for the construction of a soil-covered oil tank.

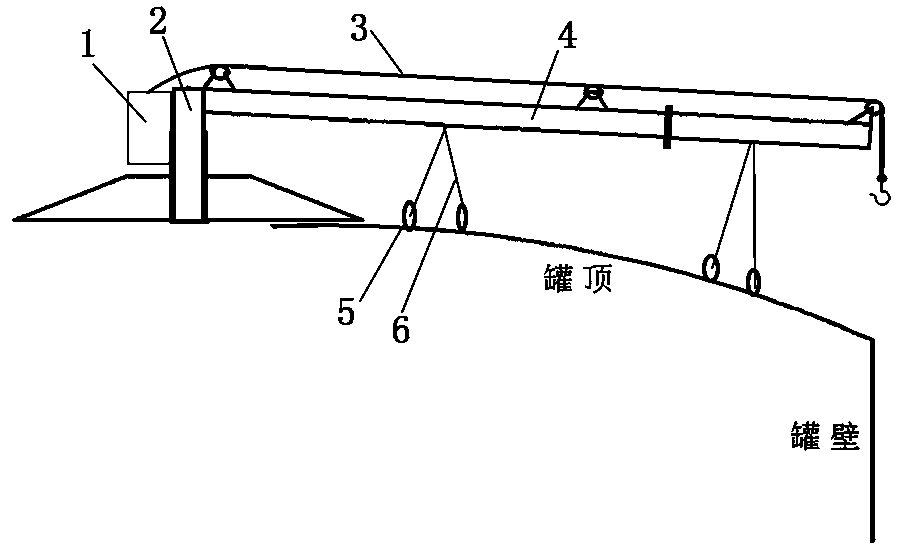

[0049] Such as figure 1 As shown, the hoisting device used for the construction of the soil-covered oil tank in the present invention includes a mast 2, a boom 4 and a hoist 1. The mast 2 stands in the middle of the tank top and can rotate around its center. The boom 4 is connected to the upper end of the mast 2. And extend outward radially of the steel storage tank, several pulleys are also installed on the boom 4, and a steel wire rope 3 is wound on the pulley, one end of the steel wire rope 3 is connected with the winch 1, and the other end is suspended outside the steel storage tank. Other tailored weldments for hoisting steel storage tanks. Suspender 4 is also provided with several supporting legs 6 along its length direction, and support leg 6 can play a supporting role to suspender 4. A caster 5 that can roll on the tank top of the steel storage tank is installed at the bottom of...

Embodiment 3

[0050] Embodiment 3: A method of using a hoisting device for the construction of a soil-covered oil tank.

[0051] Such as figure 1 As shown, the method for using the hoisting device of the present invention for the construction of the earth-covered oil tank comprises the following steps:

[0052] a. Tailor-weld the steel storage tank in the solidified reinforced concrete tank with a temporary entrance and exit. First, center the bottom of the steel storage tank in the bottom of the reinforced concrete tank.

[0053] b. After the tank bottom is tailor-welded, tailor-weld the uppermost side wall of the steel storage tank in the reinforced concrete tank.

[0054] c. Tailor-weld the roof of the steel storage tank on the uppermost side wall of the tailor-welded steel storage tank, and weld the two together.

[0055] d. Install the hoisting device for the construction of the soil-covered steel storage tank on the tank roof of the steel storage tank. The specific structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com