Automatic test system for clutch performance test

An automated testing and clutch technology, applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve the problems of insufficient control accuracy of test frequency, angle and torque, low test efficiency, and low degree of automation. Achieve the effects of improving test efficiency, high degree of automation, and improving control accuracy of angle and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

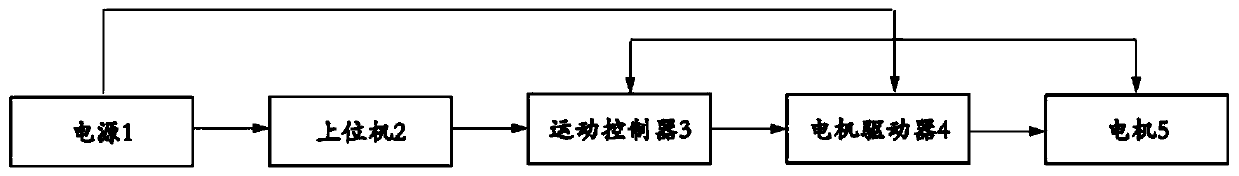

[0046] Embodiment one, as figure 1 As shown, an automated test system for clutch performance testing, including a power supply 1, a host computer 2, a motion controller 3, a motor driver 4 and a motor 5;

[0047] The power supply 1 is electrically connected to the upper computer 2, the motion controller 3, the motor driver 4 and the motor 5 respectively, and the upper computer 2 passes through the motion controller 3 and the motor driver in turn. 4 is electrically connected with the motor 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com