Two-stage refrigeration particulate matter condensation growth counter

A dual-stage refrigeration and counter technology, applied in individual particle analysis, particle and sedimentation analysis, scientific instruments, etc., can solve the problems of increasing the complexity and cost of instruments, suppress homogeneous nucleation, realize counting efficiency, improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention aims to provide a two-stage refrigerated particle condensation growth counter, which improves the activation efficiency of the particles and improves the counting efficiency of the instrument.

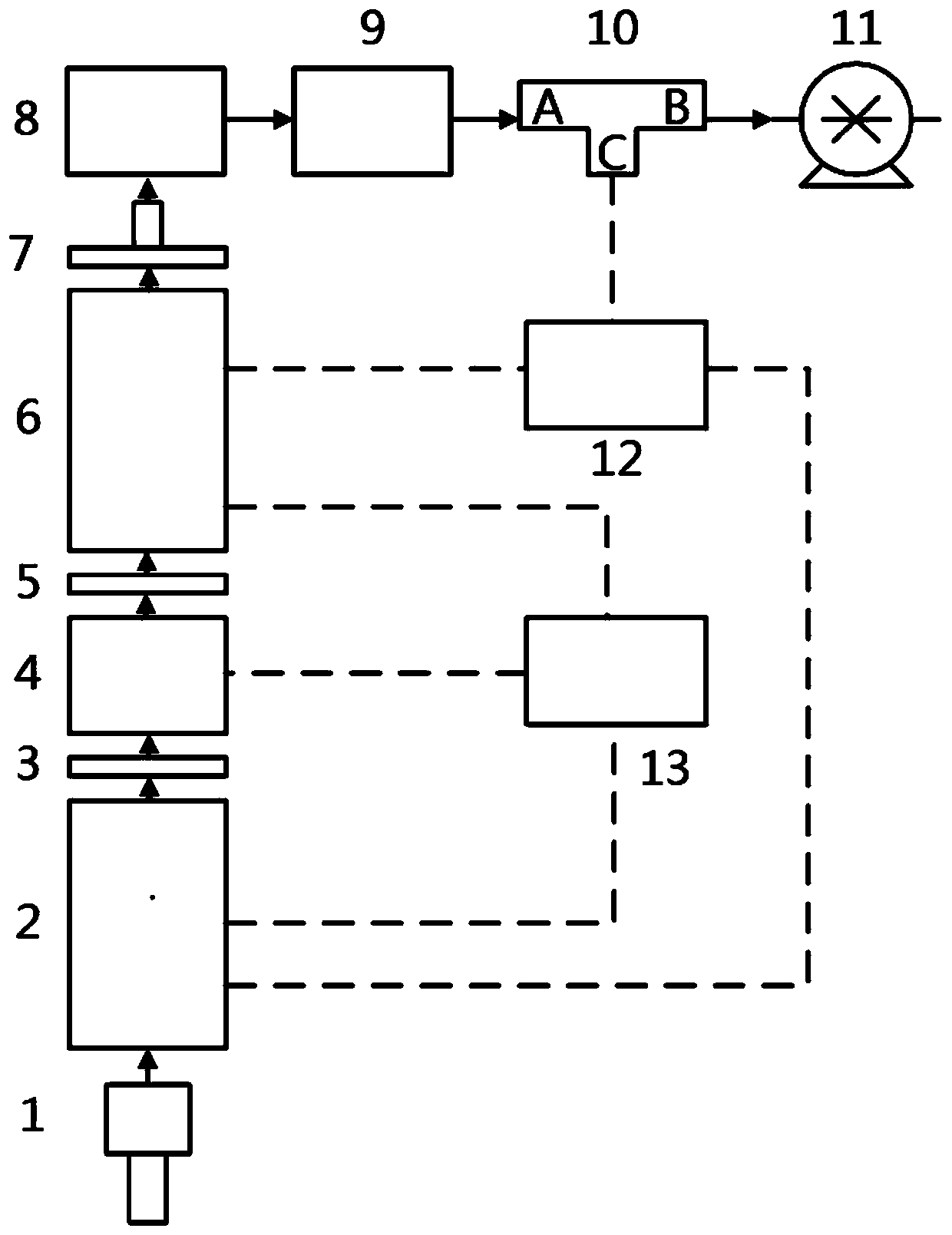

[0037] The structure of the two-stage refrigerated particle condensation growth counter is as follows:

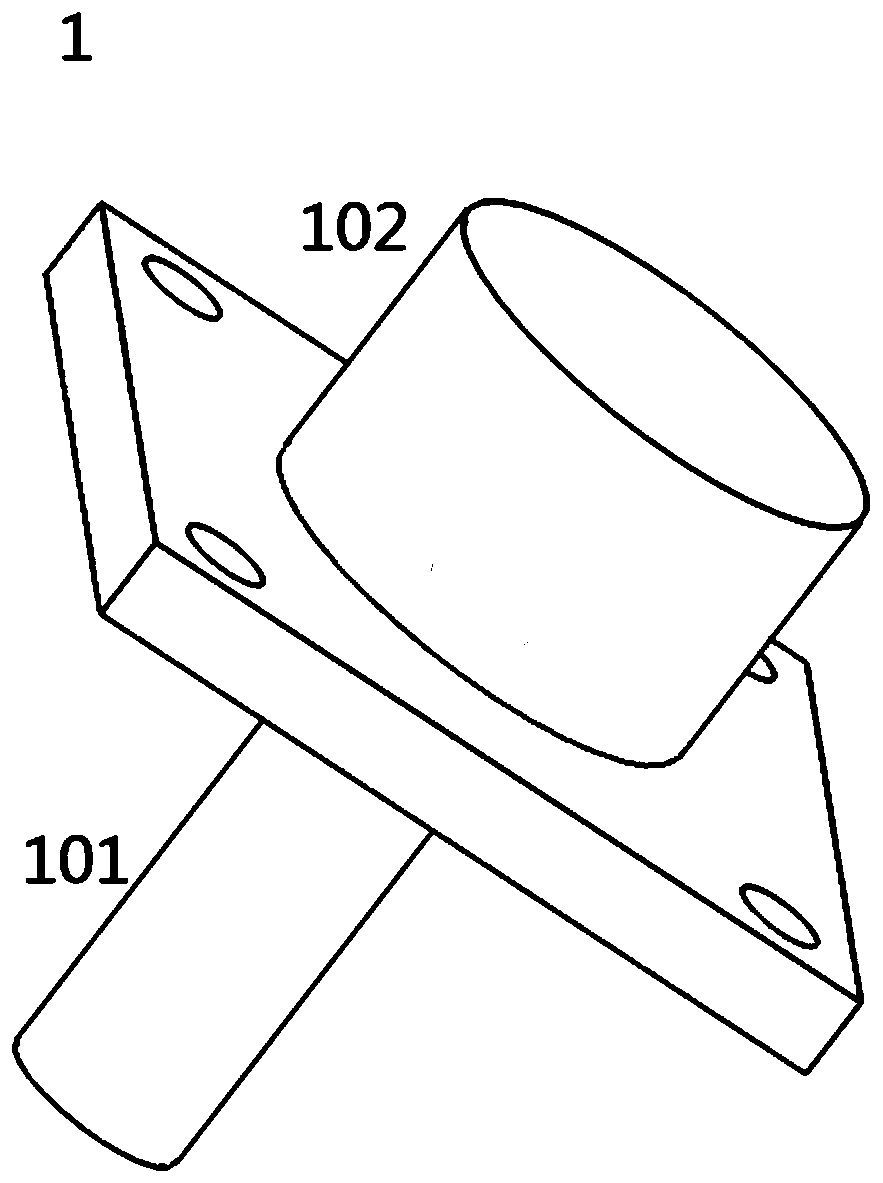

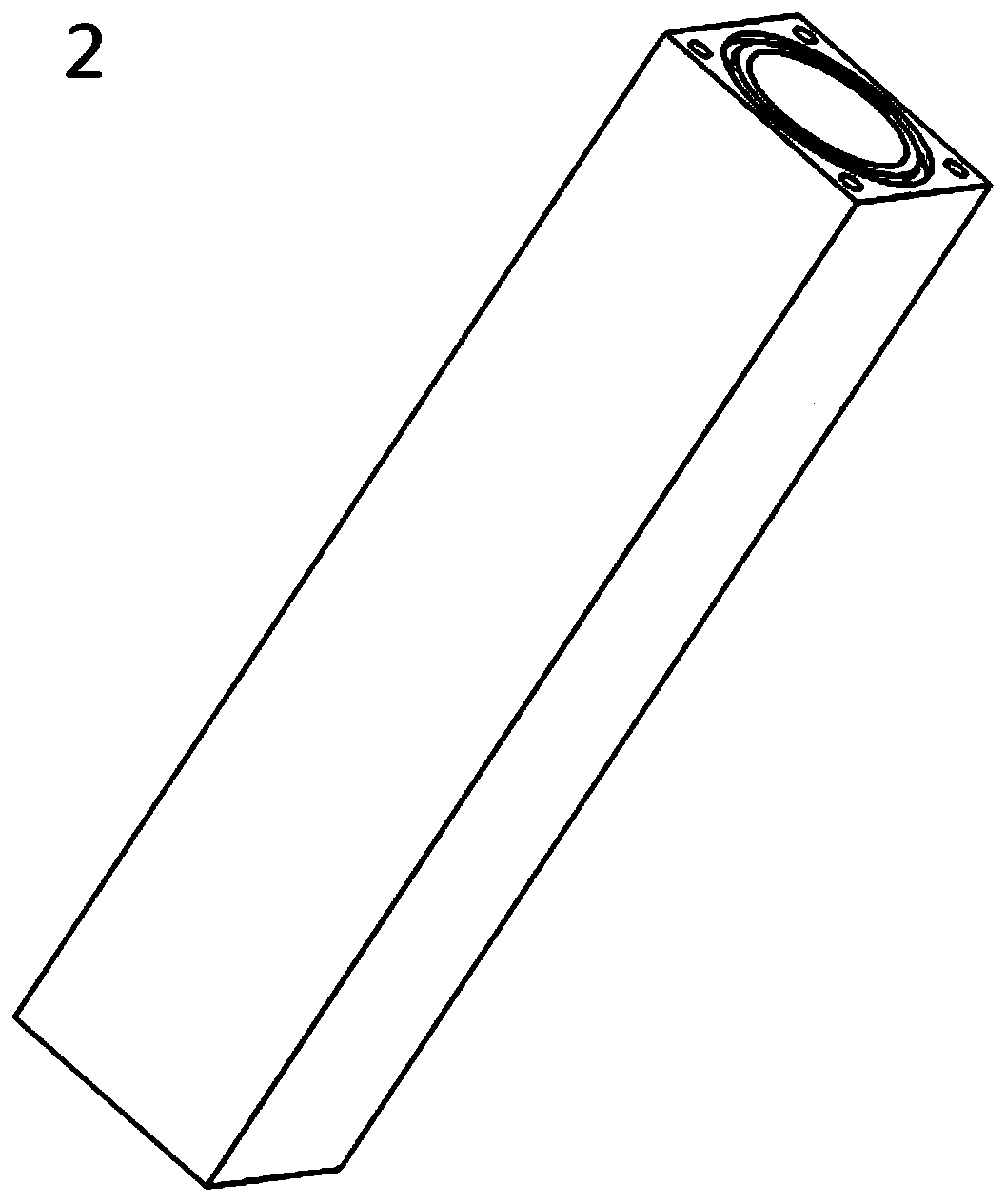

[0038] Inlet 1 is connected to the object to be sampled; the outlet of inlet 1 is directly connected to the inlet of evaporation chamber 2; the outlet of evaporation chamber 2 is directly connected to the steam-cooling heat insulator 3; ; The outlet of section 4 of the condensation chamber is connected to the condensation heat insulator 5; the other side of the condensation heat isolator 5 is connected to the inlet of the condensation chamber II section 6; the exit of section 6 of the condensation chamber is connected to the light scattering counter 8 through the nozzle 7; the light scattering The outlet of the counter 8 is connected to the restricting hole 9 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com