Treatment method of improved lithium ion battery aluminum shell

A technology of lithium-ion battery and treatment method, which is applied in the field of treatment of aluminum shells of improved lithium-ion batteries, can solve problems such as Mylar film not being able to protect bare cells, Mylar film over-melting and drawing, affecting battery energy density, etc., to achieve Improve energy density and safety, reduce coating process, and save internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

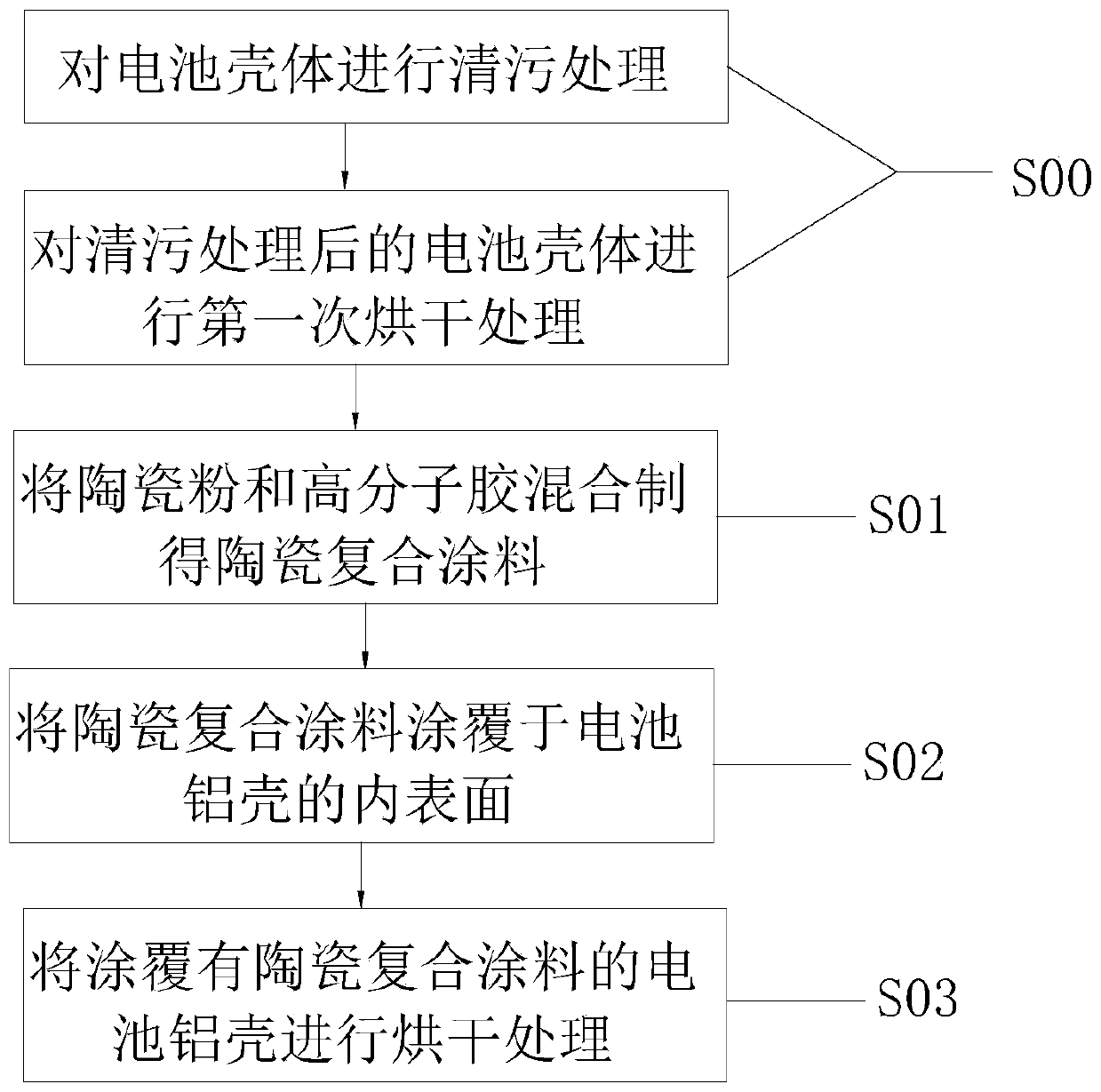

[0036] (1) Surface treatment is carried out on the aluminum shell of the battery; among them, the surface treatment can be cleaned by water spray or cleaning solution, high-pressure gas can also be used for cleaning, and ultrasonic cleaning can also be used.

[0037] (2) Carry out the first drying treatment on the surface-treated aluminum battery case; among them, the first drying treatment can be achieved by blowing hot air, so that the remaining water stains on the inner surface of the battery aluminum case can be quickly blown away and other impurities. The aluminum shell of the battery can also be dried in drying equipment such as an oven to achieve a more uniform drying treatment on the inner surface of the aluminum shell of the battery, and to completely remove the water stains remaining on the inner surface of the aluminum shell of the battery. eliminate.

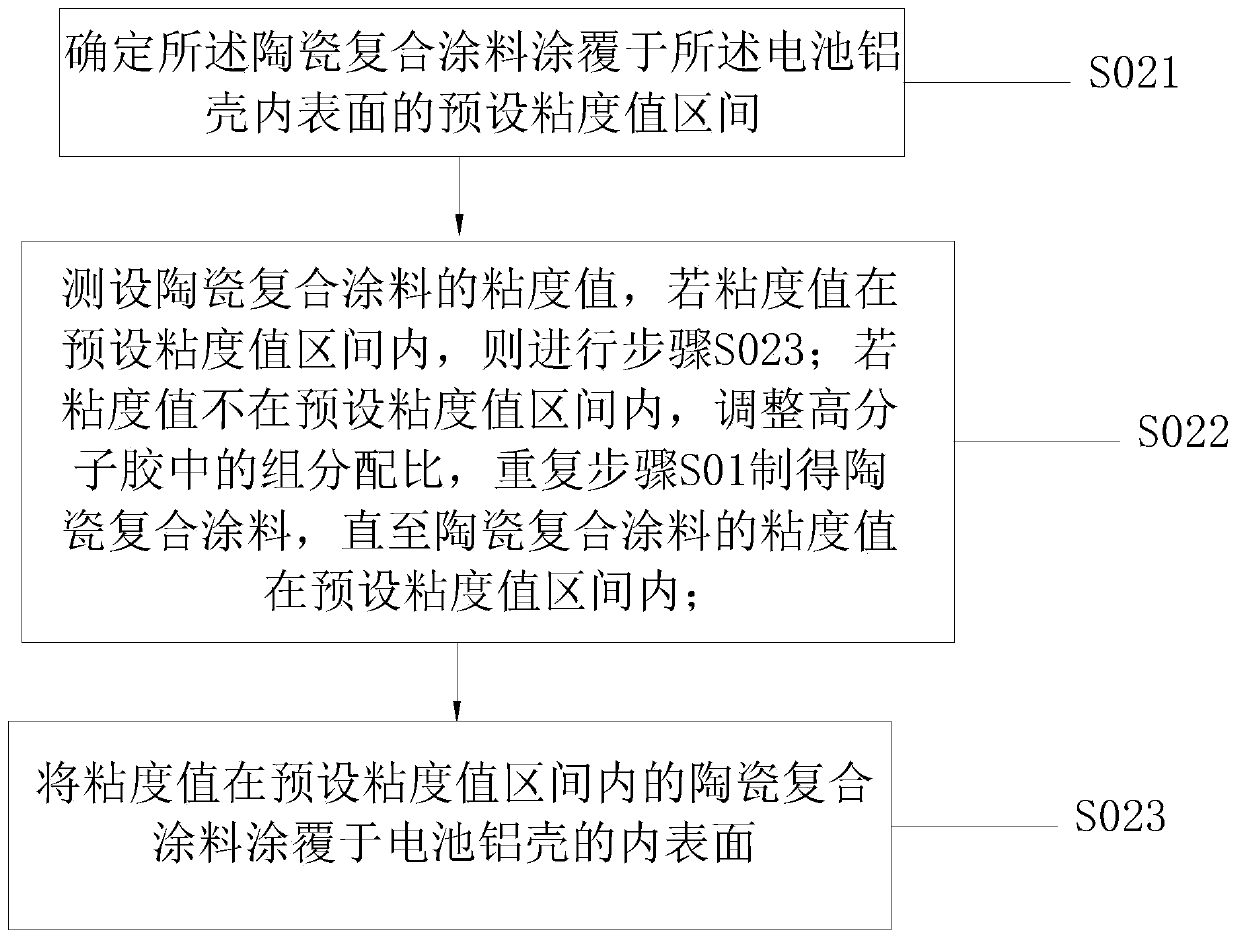

[0038] (3) Ceramic powder and polymer glue are provided, and the ceramic powder and polymer glue are uniformly mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com