Patents

Literature

36results about How to "Reduce coating process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

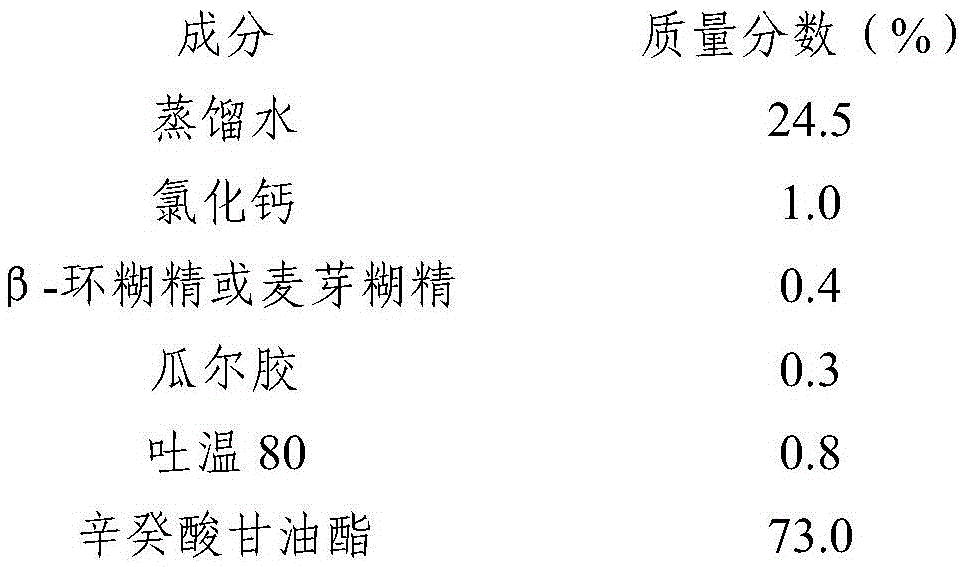

Dispersed tablet of proton pump inhibitor

InactiveCN101066251ASolve quality problemsSolve the costOrganic active ingredientsDigestive systemSodium bicarbonateDuodenal ulcer

The dispersed tablet of proton pump inhibitor is used for treating gastric ulcer, duodenal ulcer, stomal ulcer and other indications. It contains at least one kind of proton pump inhibitor and at least one kind of biologically acceptable buffering agent in the weight ratio of 1 to 10-200. The proton pump inhibitor is one selected from omeprazole, S-omeprazole, pantoprazole, lansoprazole, rabeprazole, leminoprazole, tenatoprazole and their salts. The biologically acceptable buffering agent is sodium bicarbonate, sodium carbonate, magnesium carbonate, etc or their mixture.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

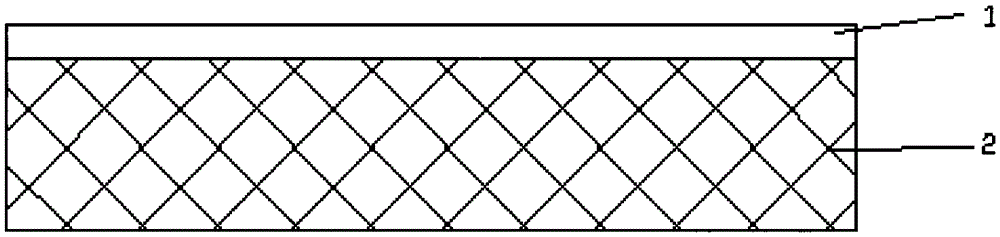

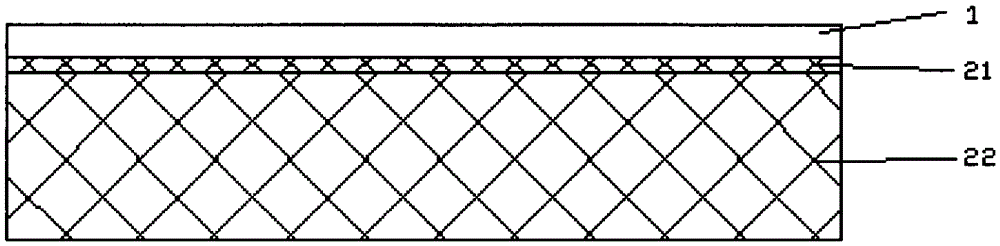

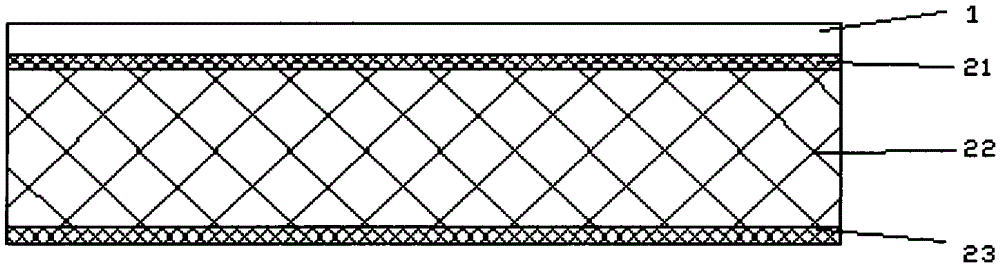

Bottom-coating-free high-protective-performance thermo-sensitive paper and making method thereof

InactiveCN105200850AReduce consumptionReduce coating processCoatings with pigmentsPaper/cardboardPulp and paper industryEnergy consumption

The invention discloses bottom-coating-free high-protective-performance thermo-sensitive paper. The high-protective-performance thermo-sensitive paper comprises a body paper layer, a face coating layer and a protective layer, wherein the face coating layer and the protective layer are arranged on the upper face of the body paper layer at a time in a coated mode. Compared with existing three-proofing thermo-sensitive paper, the bottom-coating-free high-protective-performance thermo-sensitive paper has the advantages that a coating working procedure is omitted, one coating layer is omitted, energy consumption is reduced, cost is saved, and environment friendliness is achieved; in addition, overall performance is excellent, good moisture resistance, good waterproof performance and good oil resistance are achieved, and storage performance meets the quality requirement.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

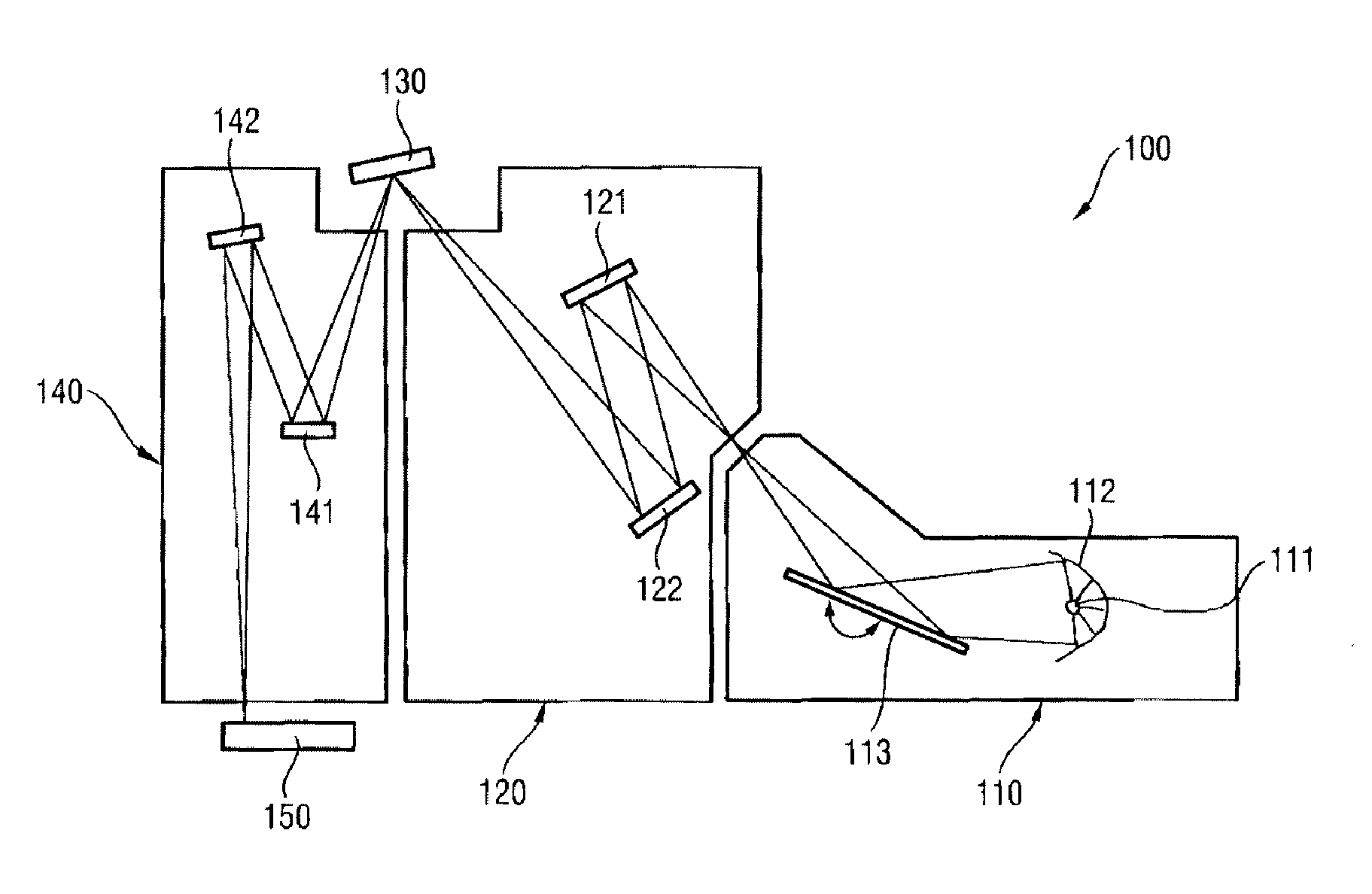

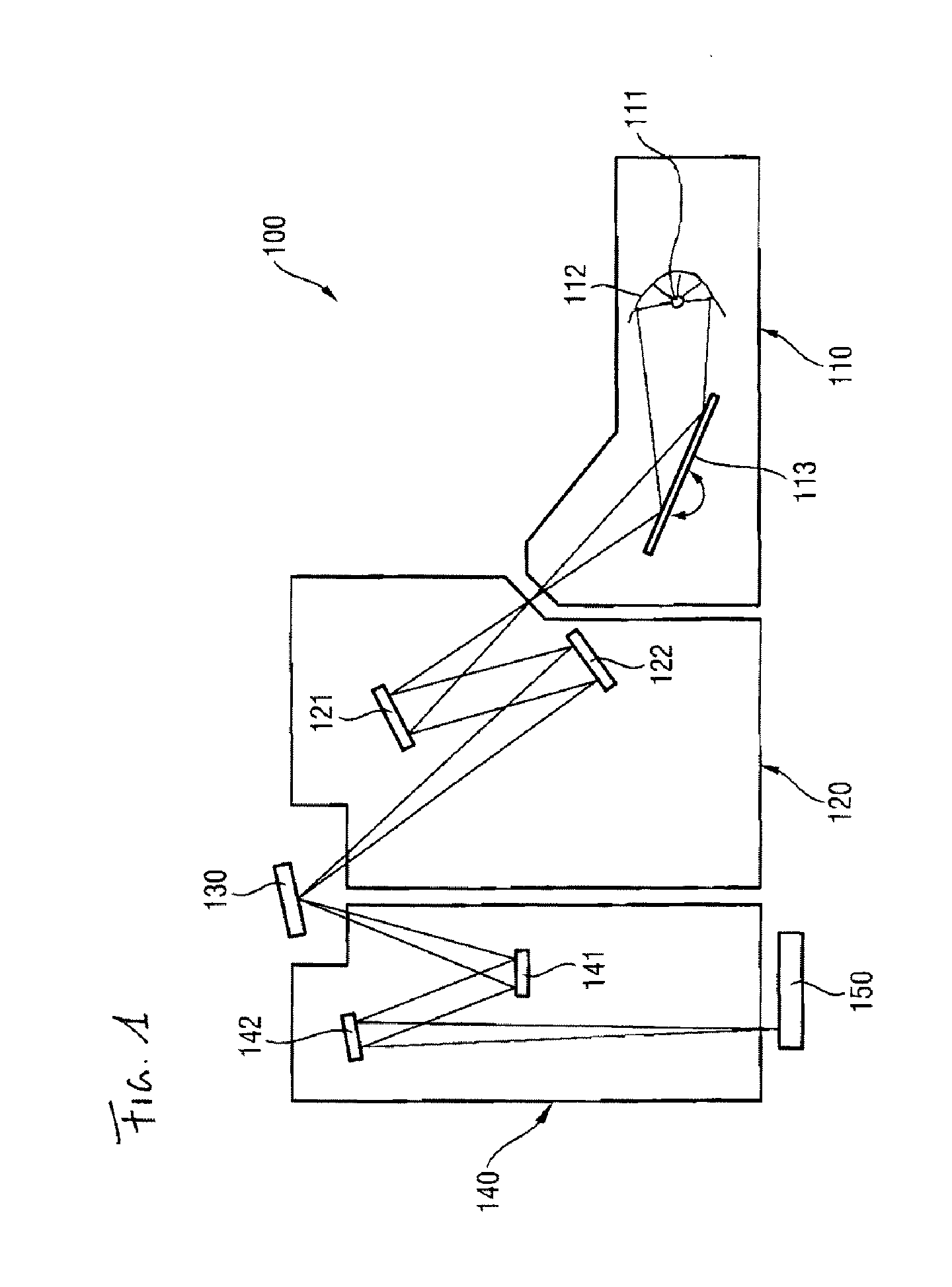

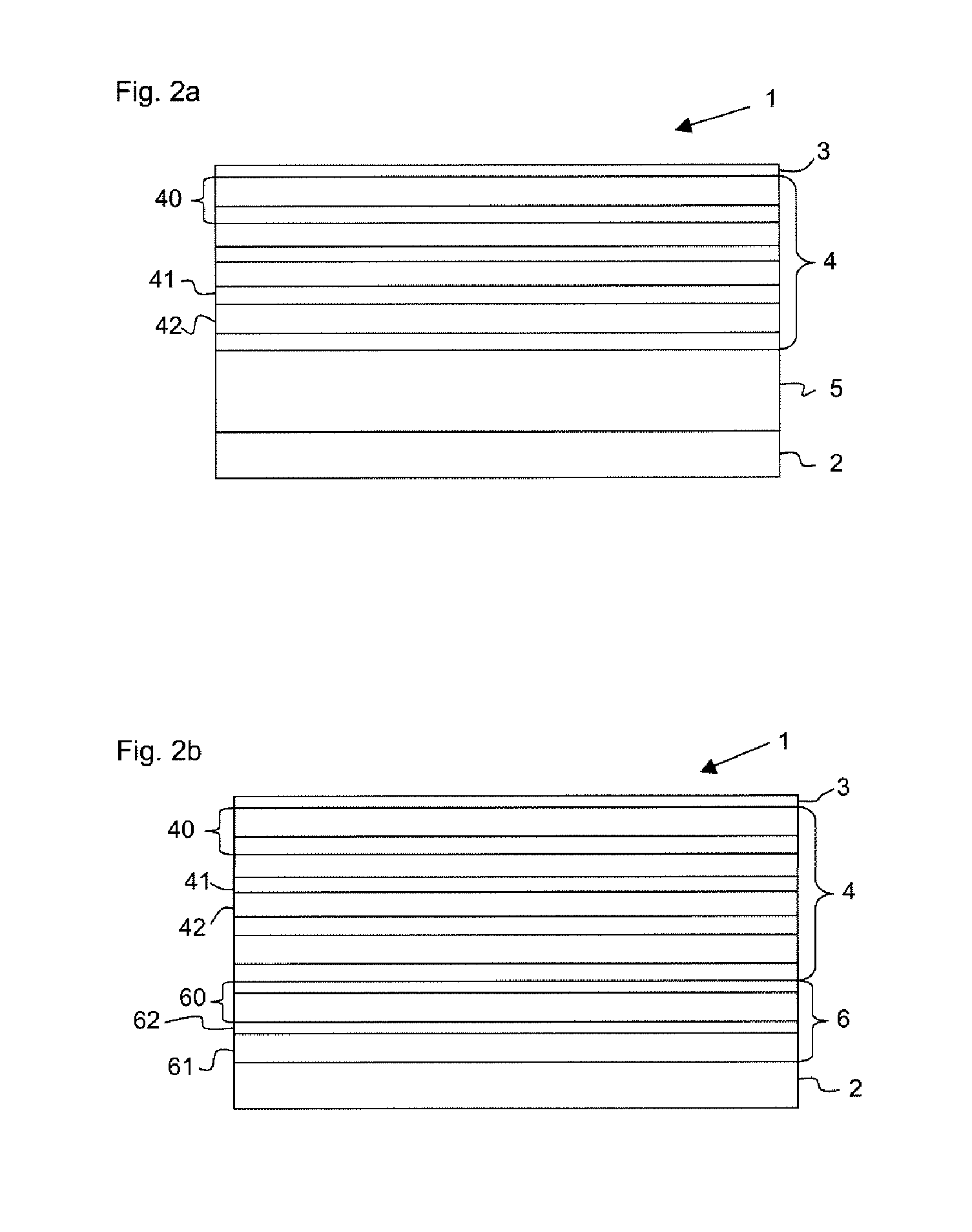

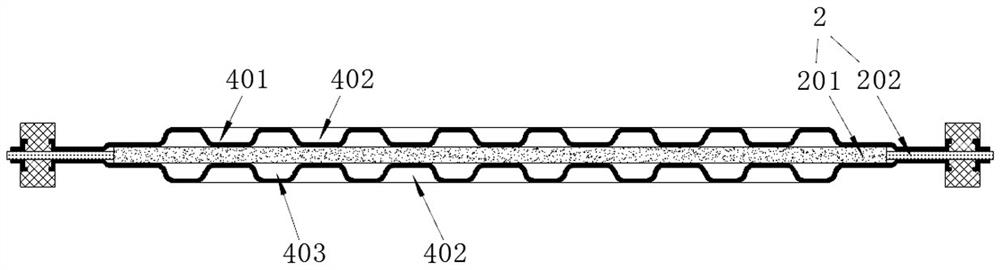

Reflective optical element and method for production of such an optical element

In order to produce stress-reduced reflective optical elements (1) for an operating wave length in the soft X-ray and extreme ultraviolet wavelength range, in particular for use in EUV lithography, it is proposed to apply, between substrate (2) and a multilayer system (4) optimized for high reflectivity at the operating wavelength, a stress-reducing multilayer system (6) with the aid of particle-forming particles having an energy of 40 eV or more, preferably 90 eV or more. Resulting reflective optical elements are distinguished by low surface roughness, a low number of periods in the stress-reducing multilayer system and also high Γ values of the stress-reducing multilayer system.

Owner:CARL ZEISS SMT GMBH

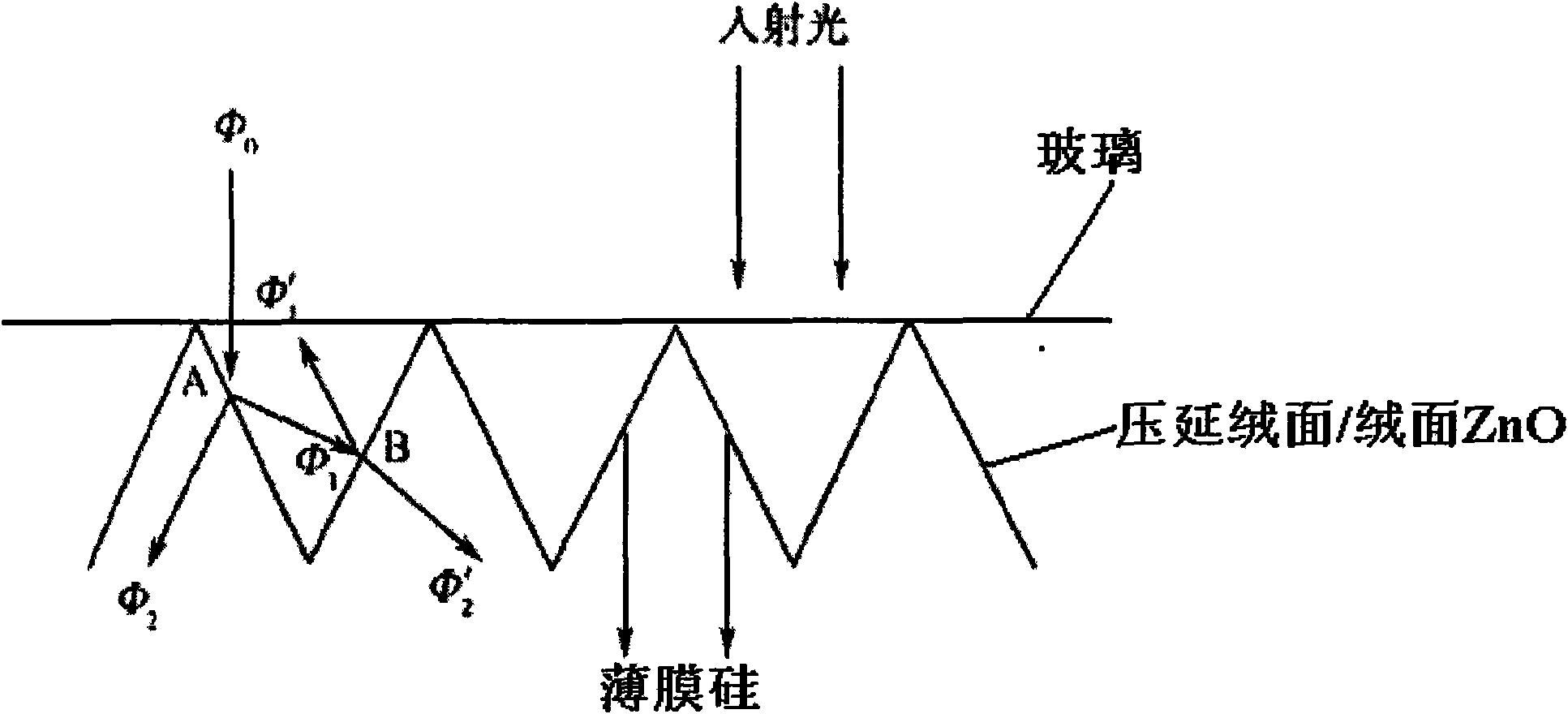

Method for preparing textured ZnO transparent conductive coated glass

InactiveCN101654331AAvoid pollutionIncrease conversion rateElectrical resistance and conductanceConductive coating

The invention discloses a method for preparing textured ZnO transparent conductive coated glass, belonging to the fields of glass finishing and silicon thin-film solar photovoltaic cells. The texturedZnO transparent conductive glass is a key material for realizing integration of photovoltaic buildings and is an important premise for improving the conversion rate of the silicon thin-film solar photovoltaic cells. In the invention, a ZnO transparent conductive coating film is prepared on the substrate of the textured glass, and the textured structure of the ZnO transparent conductive coated film is the same as that of the textured glass. The method comprises the following steps: 1) the textured glass prepared by a calendaring method is taken as glass substrates; 2) a SiO2 isolation transition layer is plated by magnetron sputtering on the surface of the textured glass, and a ZnO thin film is sputtered and precipitated on the SiO2 isolation transition layer; and 3) the structure of the formed ZnO transparent conductive textured film is consistent with the structure of the substrate of the textured glass; the textured ZnO transparent conductive glass wool degree ranges from 10 to 40%,the total transmittance of the visible light is more than or equal to 82%, and a square resistance ranges from 8 to 20 omega / square.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

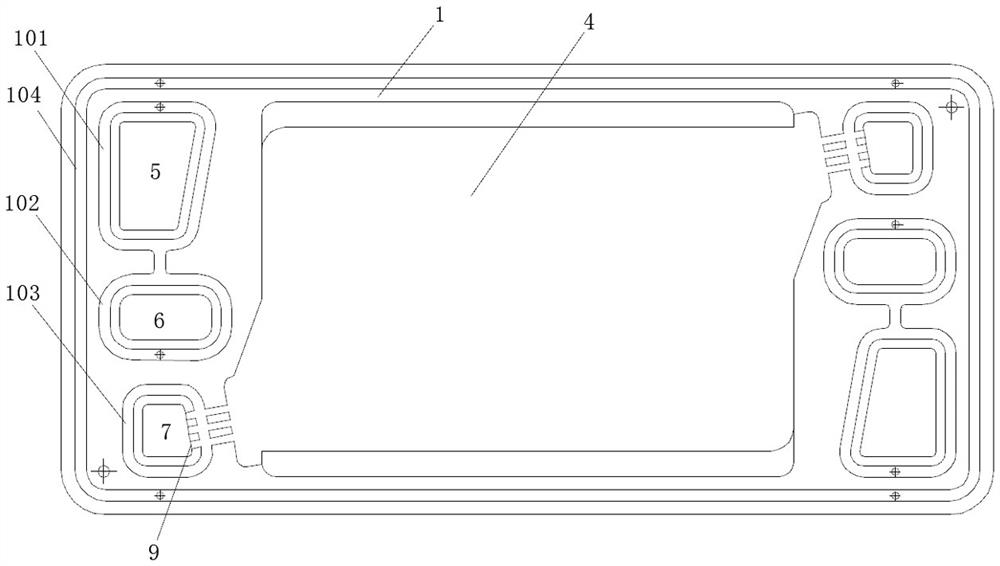

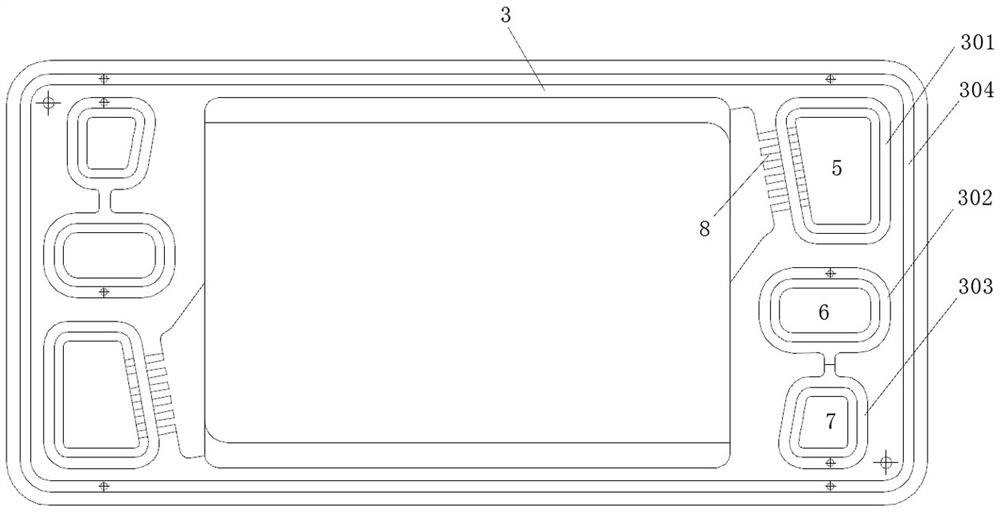

Sealing structure and sealing method of non-welded metal plate single battery

PendingCN112701315AReduce manufacturing costImprove yieldSealing/support meansStructural engineeringBattery cell

The invention relates to a sealing structure and a sealing method of a non-welded metal plate single cell, the sealing structure comprises a single cell formed by stacking an anode plate, a membrane electrode and a cathode plate together, an air main channel is communicated with a cathode flow field through an air side air inlet duct and a negative plate air side boss, and a hydrogen main channel is communicated with an anode flow field through a hydrogen side gas inlet duct by penetrating through a hydrogen side boss of an anode plate; the anode plate air side boss is communicated with the anode plate water side boss through a first channel, a first communication hole is formed in a membrane electrode frame between the anode plate water side boss and the cathode plate water side boss, and the cathode plate water side boss is communicated with the cathode plate hydrogen side boss through a second channel; and sealing rings are formed in the anode plate air side boss, the first channel, the anode plate water side boss, the cathode plate water side boss, the second channel and the cathode plate hydrogen side boss through integrated glue injection. The sealing structure and the sealing method are high in reliability, low in production cost and high in production efficiency.

Owner:FUJIAN YANAN ELECTRIC MACHINE

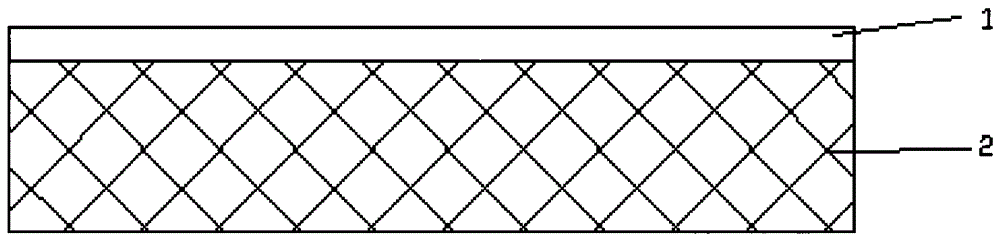

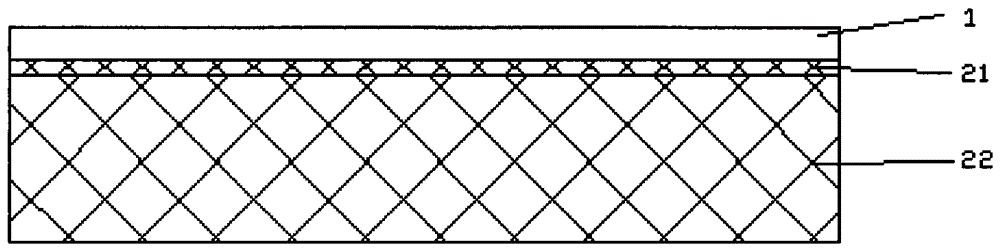

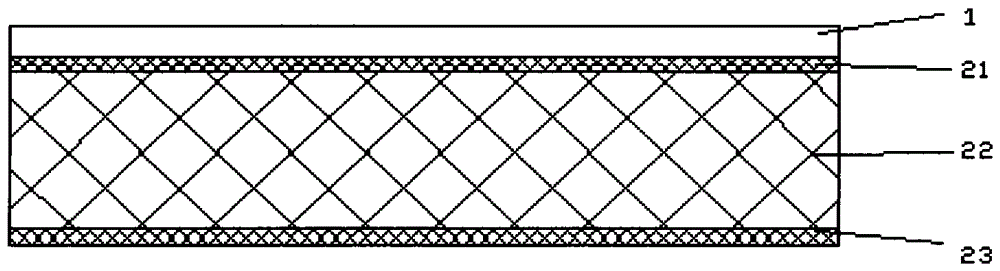

Composite panel and production method thereof

ActiveCN105346172AReduce coating processImprove adhesion stabilitySynthetic resin layered productsLaminationWaxSizing

The invention discloses a composite panel and a production method thereof. The composite panel comprises a surface layer and a plastic composite base material layer, which are subjected to thermocompression bonding; the production method of the composite panel comprises the following steps: proportionally weighing and mixing PVC powder, heavy calcium and light calcium composite powder, a stabilizer, a flexibilizer, PE wax, an inner lubricant, a plasticizer and an impact modifier, and fully stirring a mixture for mixing; extruding the mixed mixture through an extrusion machine to synthesize a plastic composite base material; bonding the surface layer and the plastic composite base material layer together; finally, cooling, sizing and cutting. According to the adoption of the above technical solution, the plastic composite base material does not use wood powder and can save natural timbers; the surface layer and the plastic composite base material are thermally compressed and bonded together without using glue and without containing formaldehyde, the composite panel is formed by one step and a glue coating process is removed, continuous production is easy to realize, and production efficiency is improved; bonding stability among layers of the composite panel is improved.

Owner:WELLMADE FLOOR IND CO LTD

Light diffusing polyester film

InactiveCN104793274AGood light transmission performanceSufficient optical diffusionDiffusing elementsPolyesterSurface layer

The invention discloses a light diffusing polyester film comprising an intermediate layer and two surface layers, wherein the intermediate layer and the surface layers are mainly made of polyester. The intermediate layer is doped with 0.1-3% of light diffusing particles and 0.3-10% of at least two thermoplastic incompatible resins. The surface layers are doped with 1-15% of light diffusing particles. The surface layers are arranged on the two sides of the intermediate layer, and are formed by the steps of co-extruding through an extruder, pulling and heat setting. The polyester film with full light transmission and light diffusion performances is prepared directly by a two-way pulling technology. The light diffusion performance is greatly improved on the premise of limited decrease of the light transmission performance. The problem of environment pollution brought by a subsequent coating process is avoided.

Owner:南京亚博联新材料科技股份有限公司

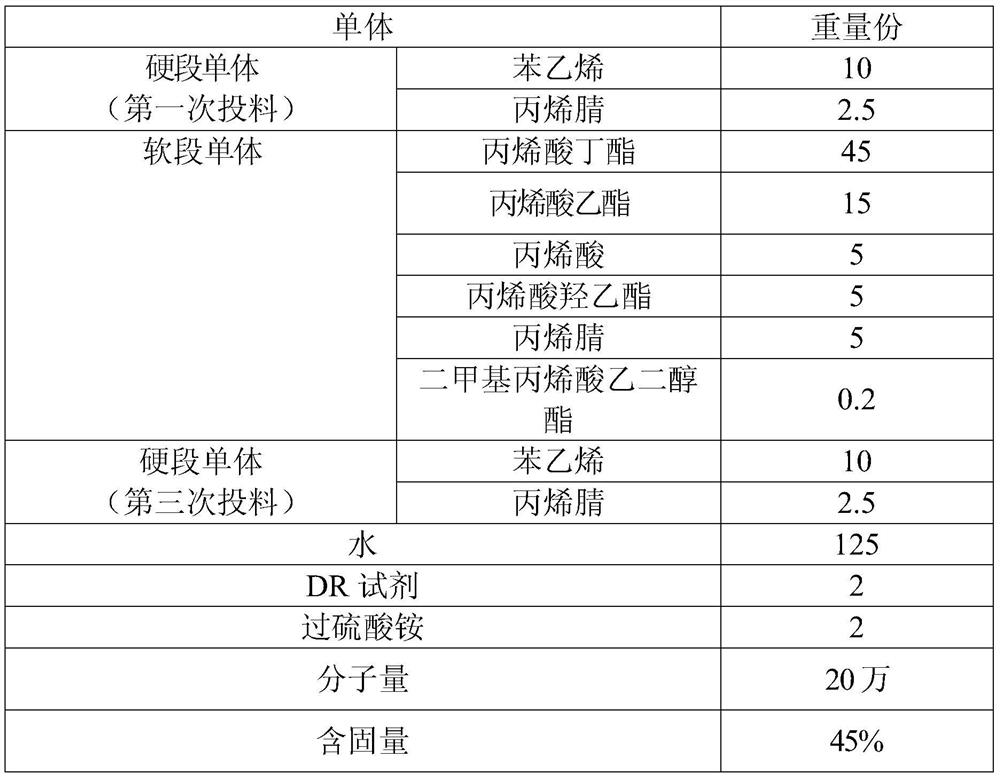

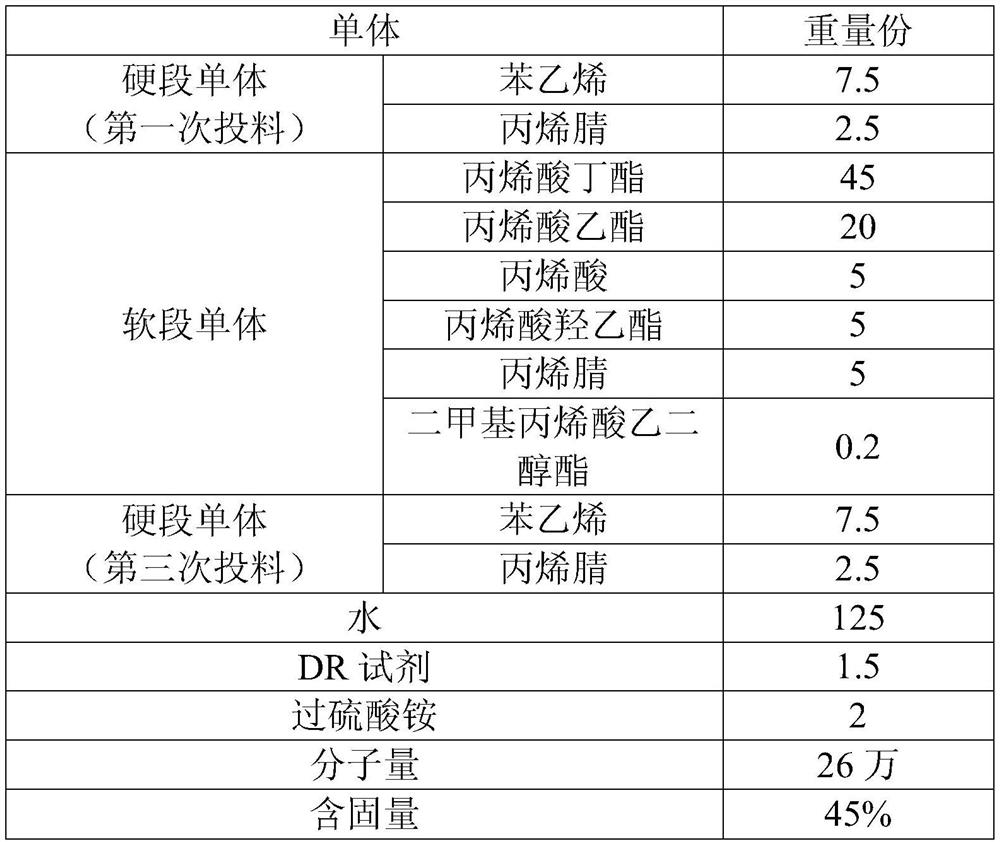

Plasticizer-migration-resistant water-based pressure-sensitive adhesive and preparation method thereof

ActiveCN112126389AIncrease elasticityImprove fatigue resistanceNatural rubber adhesivesRosin adhesivesPolymer scienceAdhesive

The invention relates to the technical field of adhesives, and discloses a plasticizer-migration-resistant water-based pressure-sensitive adhesive and a preparation method of the plasticizer-migration-resistant water-based pressure-sensitive adhesive. The adhesive comprises the following components in parts by weight: 20-60 parts of a block copolymer, 1-20 parts of natural rubber emulsion or styrene-butadiene latex, 0.1-2 parts of a pH regulator, 1-15 parts of a plasticizer, 1-15 parts of deionized water, 1-40 parts of water-based tackifying resin, 0.01-3 parts of a wetting agent and 0.1-1 part of an antibacterial agent. The aqueous pressure-sensitive adhesive is resistant to plasticizer migration and provides lasting, excellent initial adhesion, high peel strength and persistent adhesionwhen used on a soft polyvinyl chloride substrate. The preparation method comprises the following steps of: mixing the block copolymer and the natural rubber emulsion, adjusting the pH value, adding the plasticizer and the deionized water, mixing, standing, and adding the water-based tackifying resin and other assistants to obtain the water-based pressure-sensitive adhesive. The preparation methodhas the advantages of simple process operation, no need of heating, low overall cost and easy realization of industrial production.

Owner:英创新材料(绍兴)有限公司

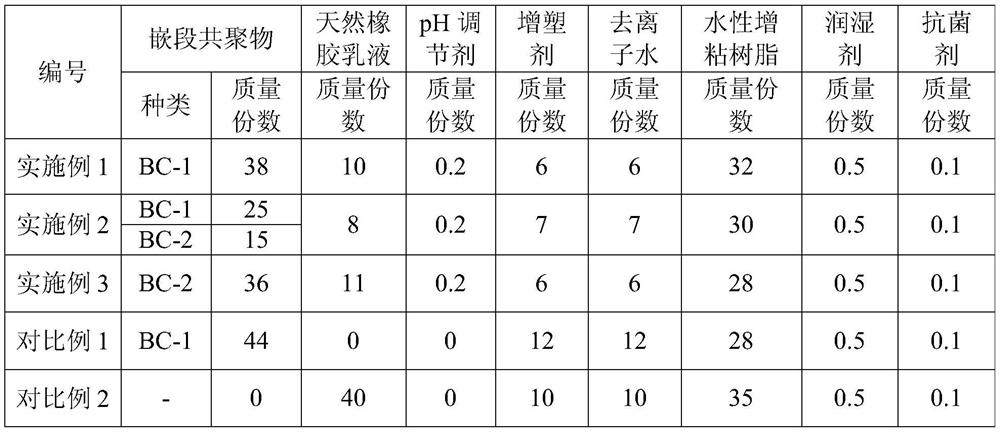

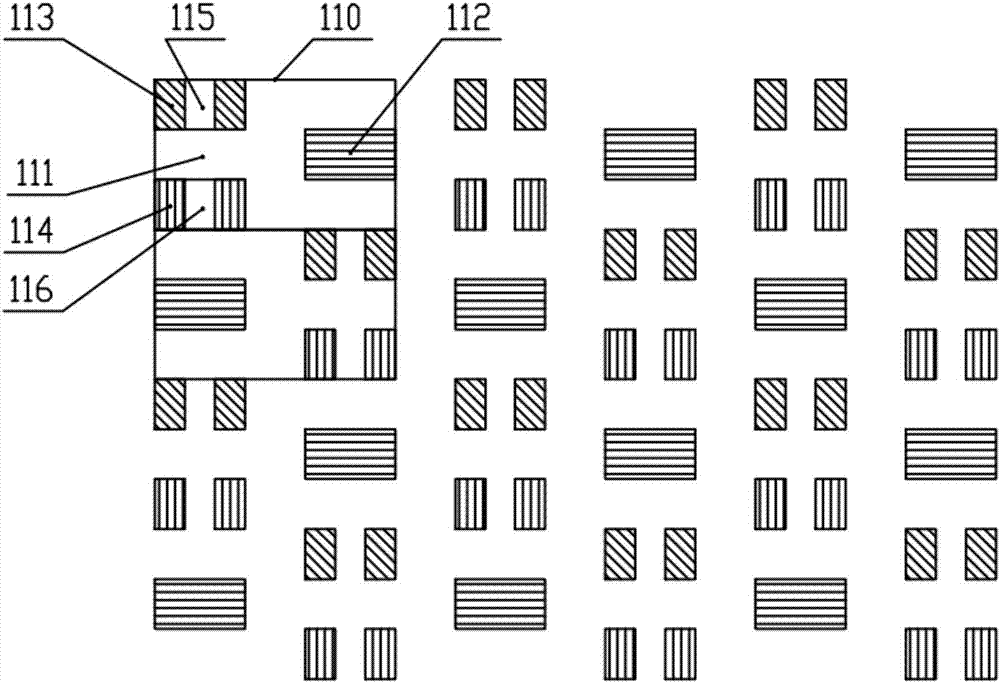

Organic light-emitting diode (OLED) display panel and display device

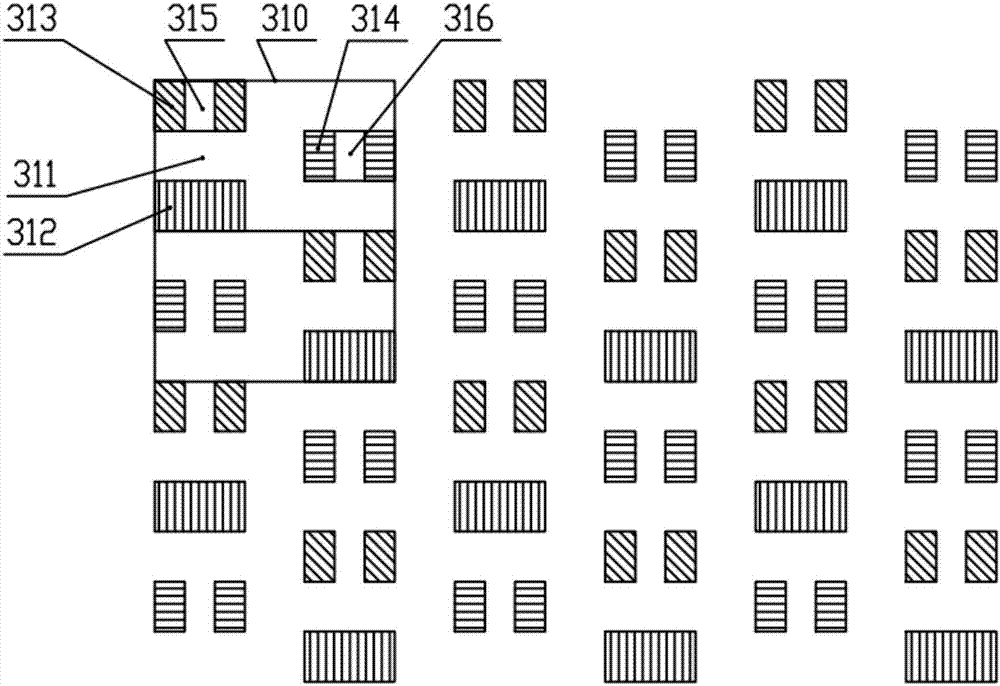

PendingCN107248522AImprove display quality and effectsRequirement to reduce array densityStatic indicating devicesSolid-state devicesImage resolutionDisplay device

The invention provides an organic light-emitting diode (OLED) display panel and a display device. The OLED display panel comprises at least two pixel group units, wherein the at least two pixel group units are arranged along a first direction or a second direction, each pixel group unit comprises two sub-pixel group units arranged along the second direction, each sub-pixel group unit comprises a first sub-pixel, a second sub-pixel and a third sub-pixel, two adjacent second sub-pixels form a second sub-pixel group, two adjacent third sub-pixels form a third sub-pixel group, and arbitrary three adjacent first sub-pixels, arbitrary three adjacent second sub-pixels and arbitrary three adjacent third sub-pixels form a basic pixel unit. The OLED display panel has the beneficial effects that adjacent sub-pixels or sub-pixel groups are shared by the sub-pixels, so that the OLED display quality and effect are improved on the same number of sub-pixels, or the requirement on sub-pixel arrangement density of a display is reduced on the condition that the same sensing resolution is maintained unchanged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

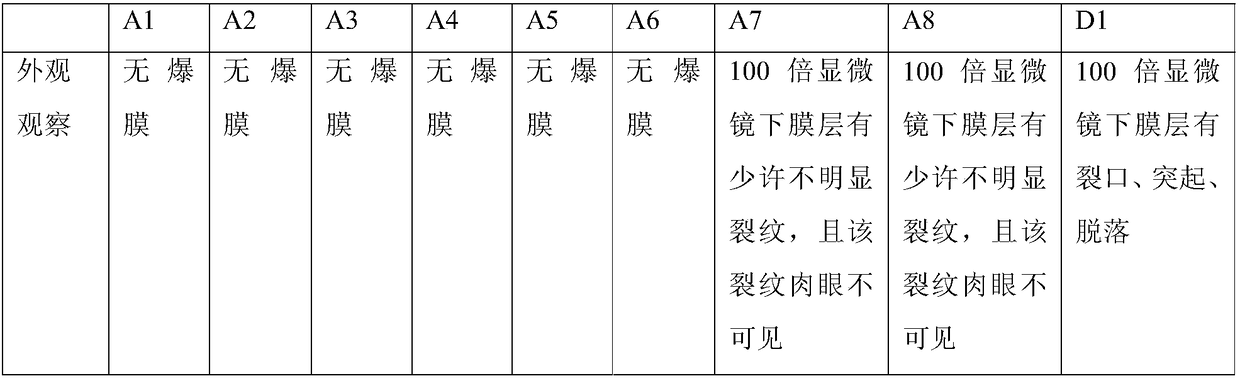

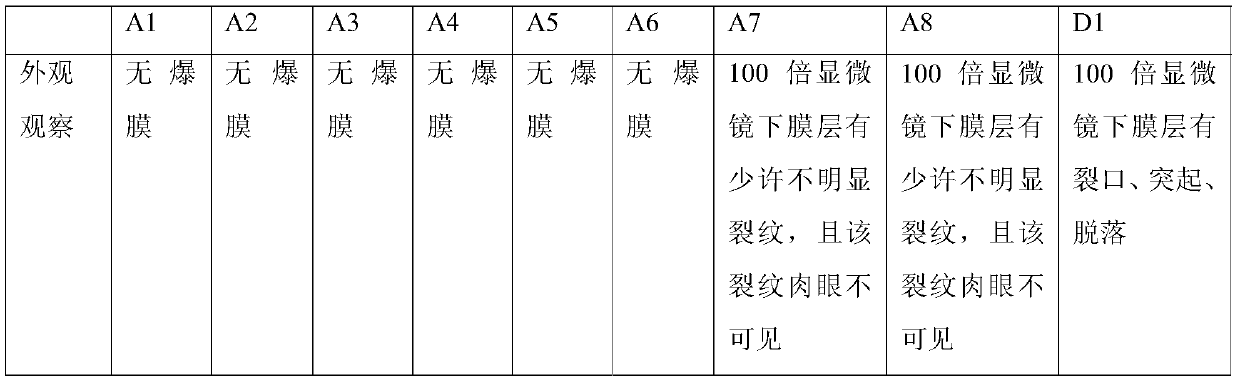

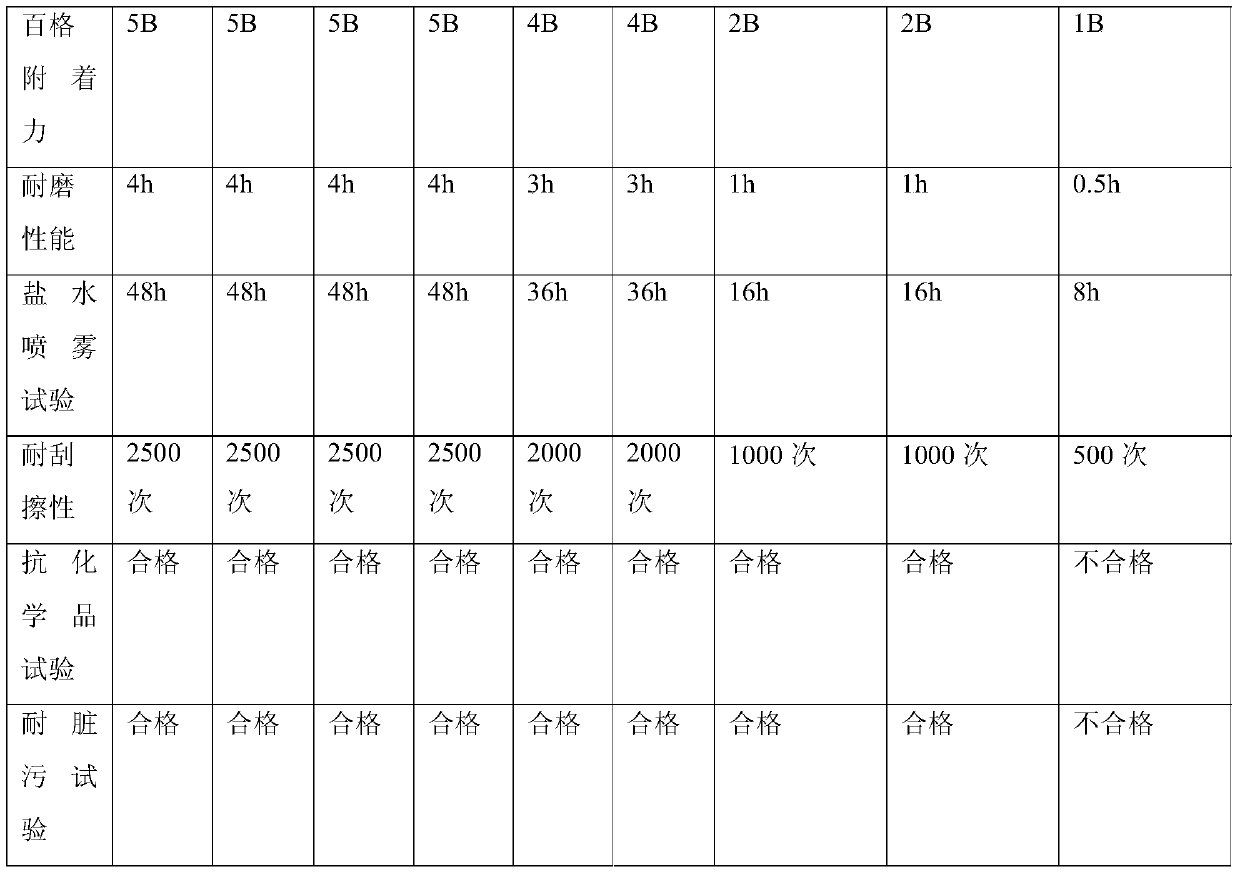

Method of forming double-color double-texture PVD film layer on metal substrate and metal substrate obtained thereby

ActiveCN108239745AStrong adhesionImprove adhesionVacuum evaporation coatingSputtering coatingSand blastingPrinting ink

The invention relates to the technical field of pattern processing and discloses a method of forming a double-color double-texture PVD film layer on a metal substrate and the metal substrate obtainedthereby. The method comprises the following steps: (1) carrying out primary PVD coating treatment on the metal substrate to form a bottom film layer and a top film layer different in color on the metal substrate; (2) designing a needed pattern on the top film layer, and coating shielding printing ink to the pattern region to be cured; (3) carrying out sand blasting treatment on the substrate obtained in the step (2); (4) removing the top film layer exposed in a non-pattern region; and (5) removing the shielding printing ink cured in the pattern region. The method can plate the double-color double-texture PVD film layer on the metal substrate at one time within a same furnace body without a film exploding phenomena, so that the PVD coating step is reduced, the time is shortened greatly, thecost is lowered, and the product yield is increased obviously.

Owner:BYD CO LTD

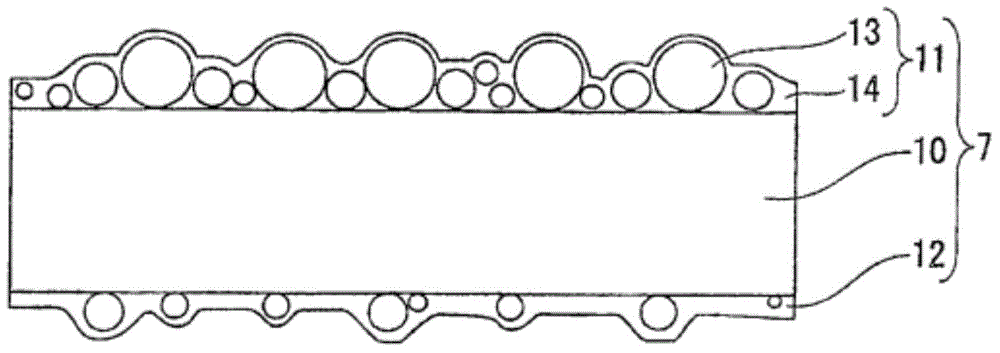

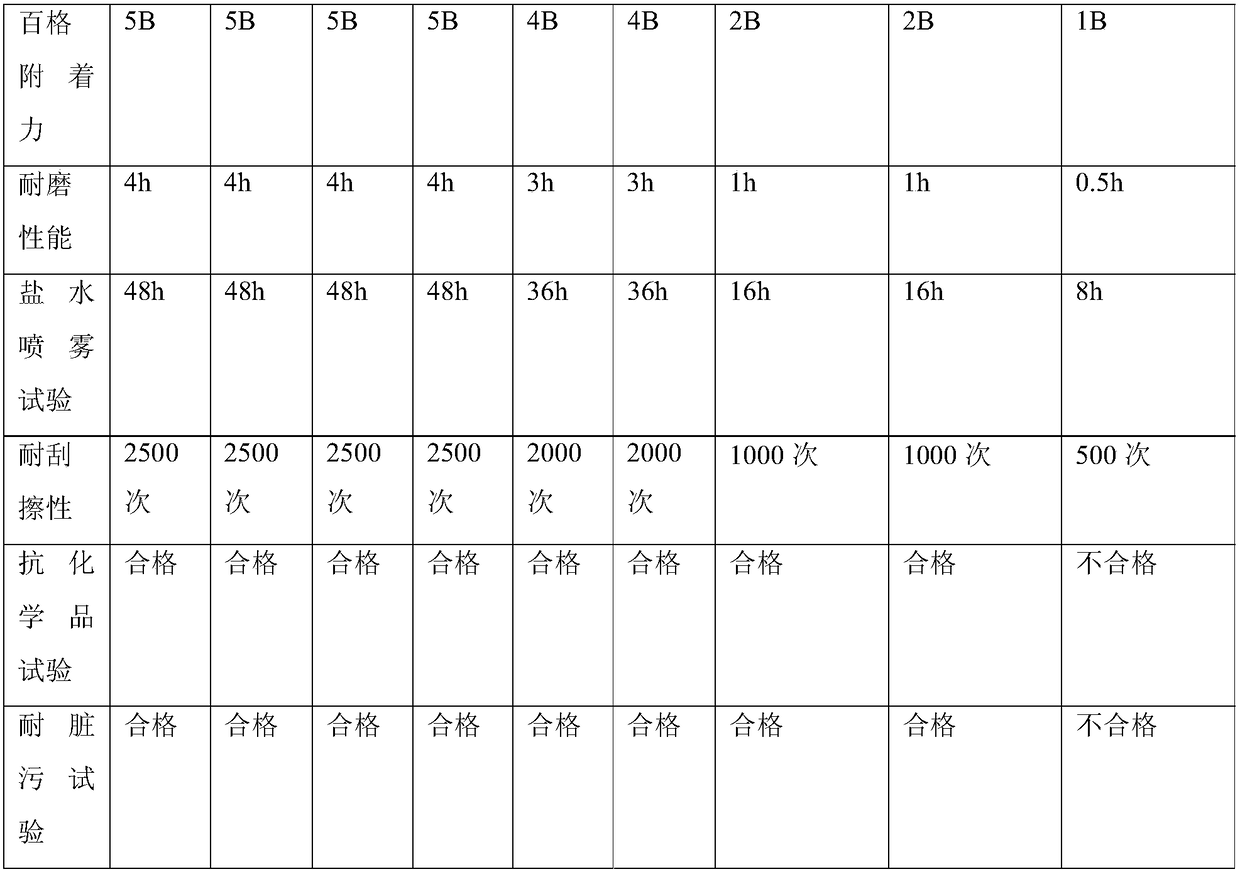

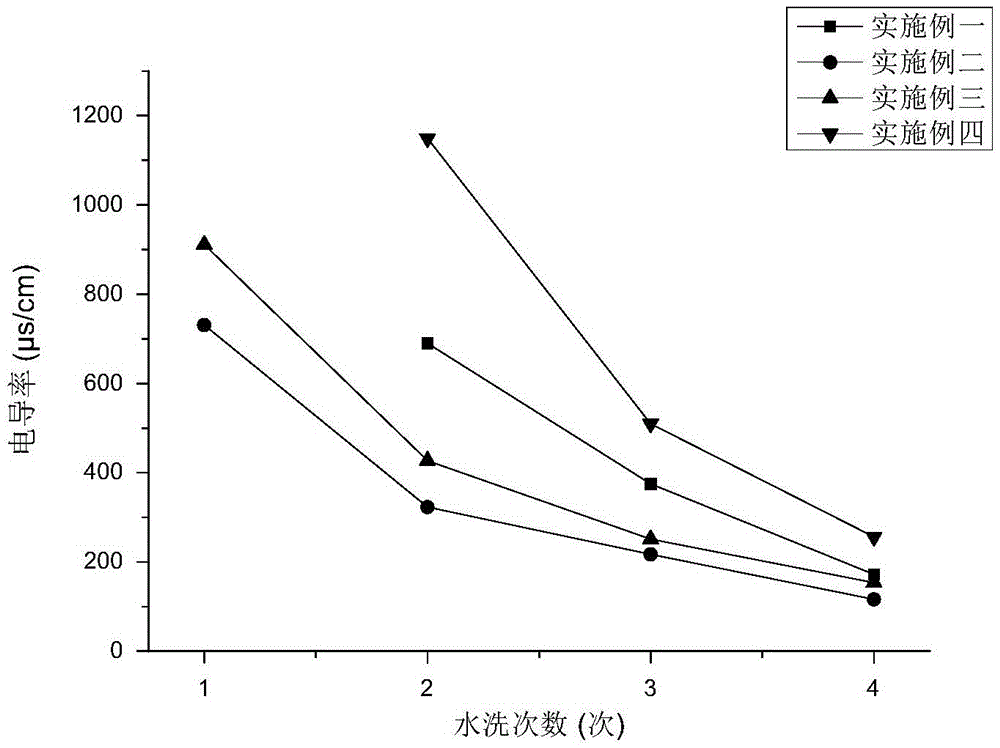

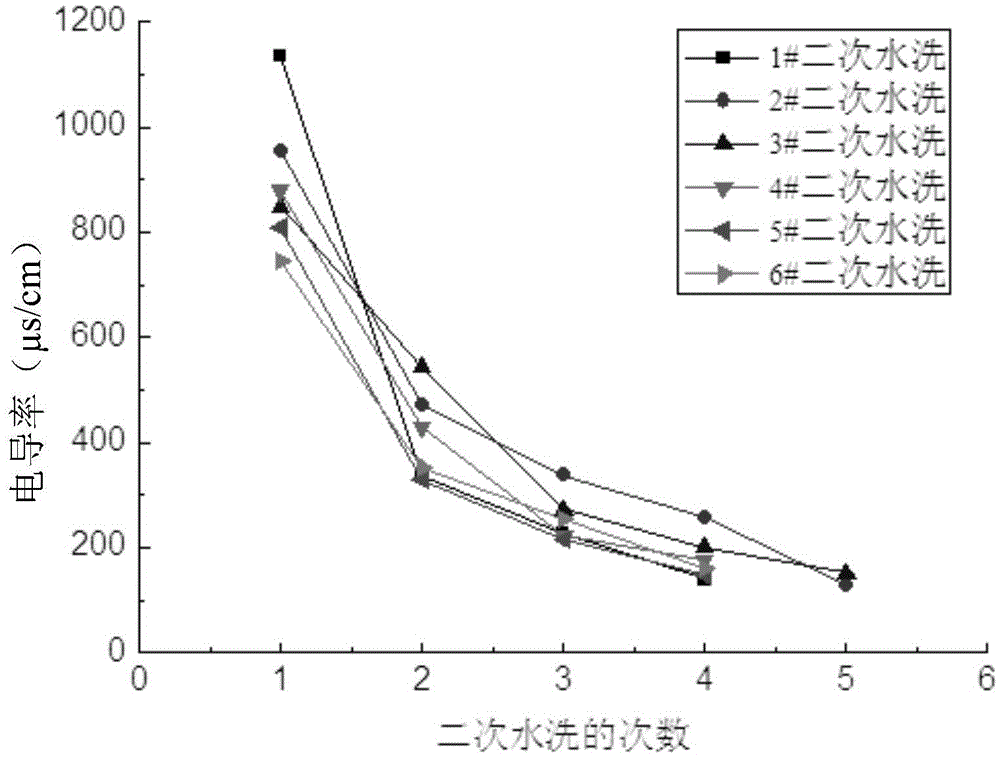

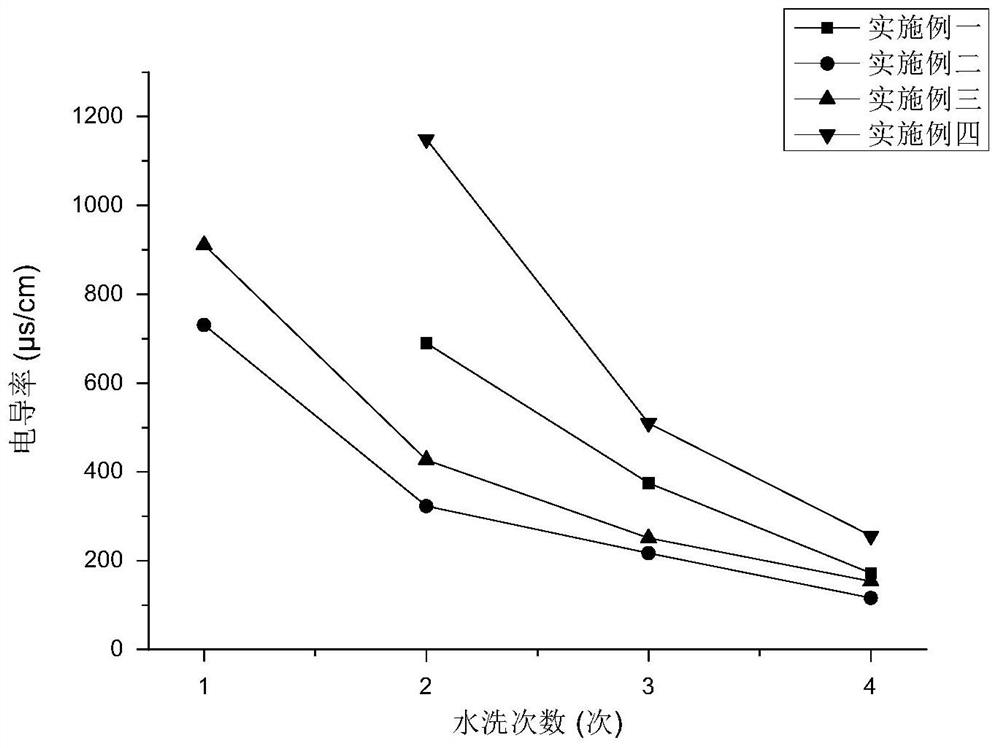

Brittle capsules for tobacco products and production method and application thereof

ActiveCN105536656AImprove brittlenessHigh mechanical strengthMicroballoon preparationMicrocapsule preparationHigh humidityEngineering

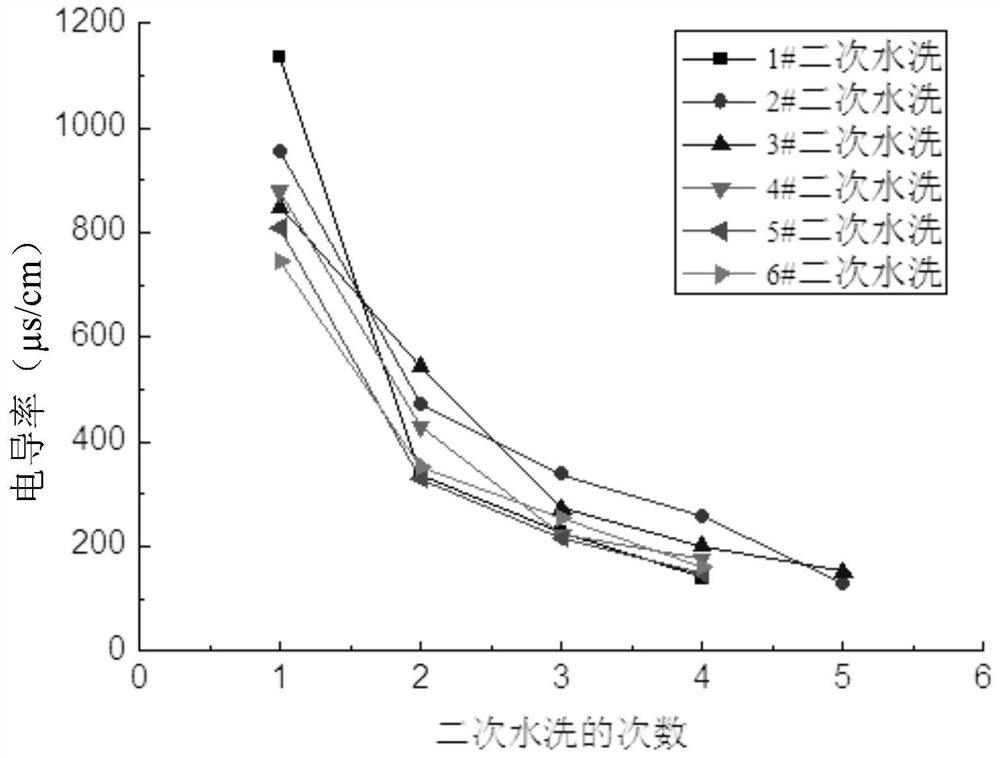

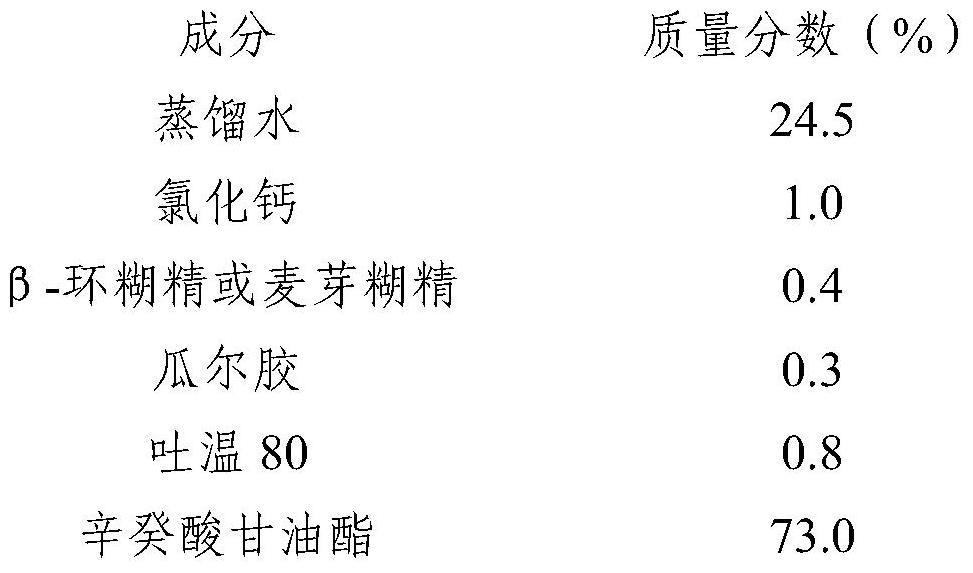

The invention relates to a method for producing brittle capsules for tobacco products; in a second-time water washing process, the water consumption amount, the number of water washing times and the electric conductivity are strictly controlled, removal of excess ions is quantitatively controlled, and finally, capsule brittleness is achieved and the brittleness can be kept in high-temperature and high-humidity environment without coating. The invention also provides the brittle capsules used for the tobacco products and prepared according to the method and an application thereof.

Owner:CHINA TOBACCO GUIZHOU IND

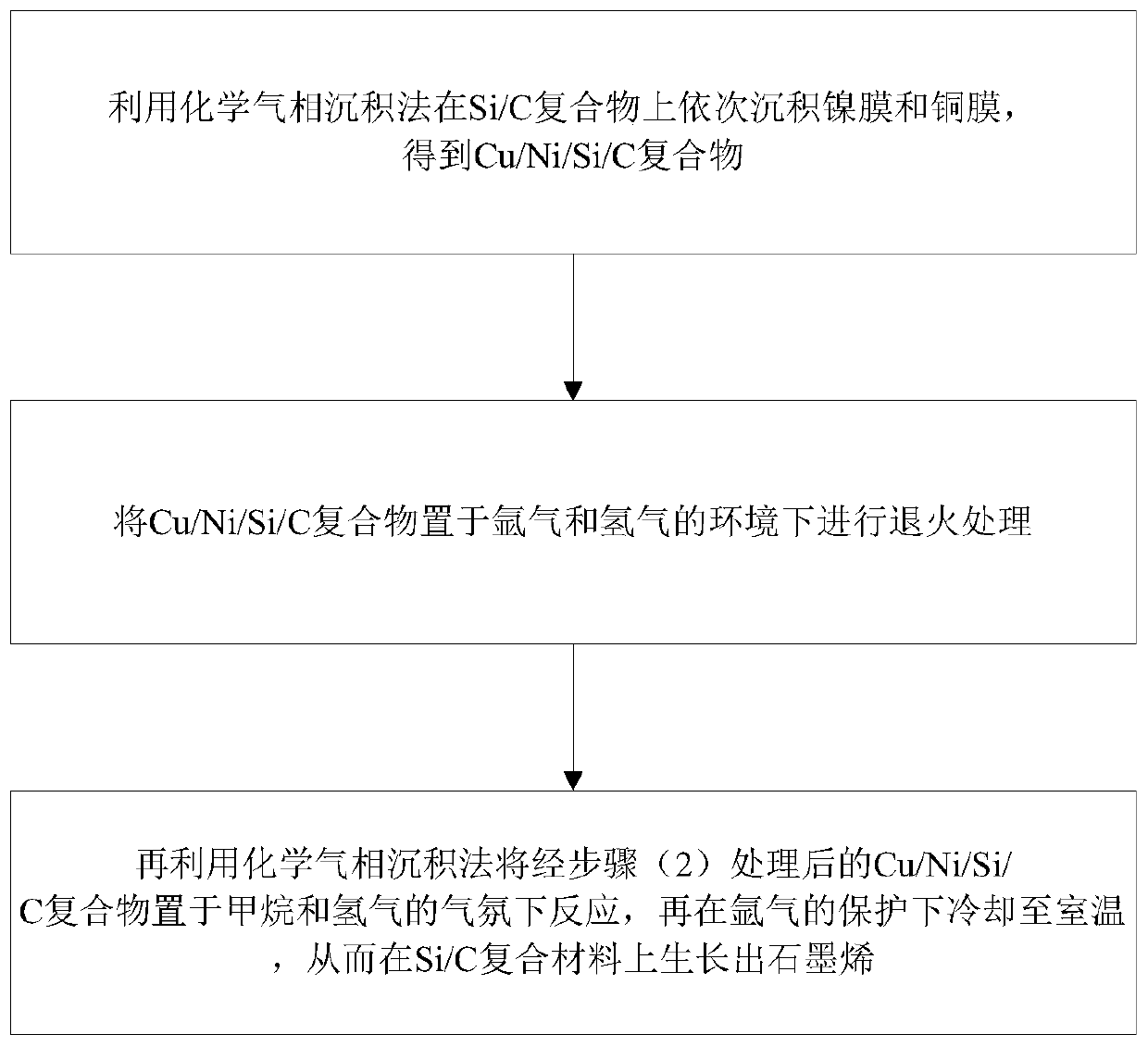

Method for growing graphene on Si/C composite material, material obtained through such method, and application of such material

InactiveCN109742379AIncrease charging rateReduce process stepsCell electrodesGrapheneHydrogen atmosphereRoom temperature

The invention relates to a method for growing graphene on a Si / C composite material, a material obtained through such method, and application of such material. The method comprises the following steps: (1) orderly depositing a nickel film and a copper film on Si / C compound through a chemical vapor deposition method, and obtaining Cu / Ni / Si / C compound; (2) placing the Cu / Ni / Si / C compound in argon and hydrogen environment and performing annealing treatment; (3) placing the Cu / Ni / Si / C compound treated in the step (2) in methane and hydrogen atmosphere to react through the chemical vapor depositionmethod, cooling to room temperature under protection of argon, and consequently, growing out the graphene on the Si / C composite material. With the method provided by the invention, adding of the graphene in a battery core material or transfer and coating technologies for a graphene thin film are reduced, and damage to chemical properties of the existing graphene can be avoided.

Owner:哈工大机器人(岳阳)军民融合研究院

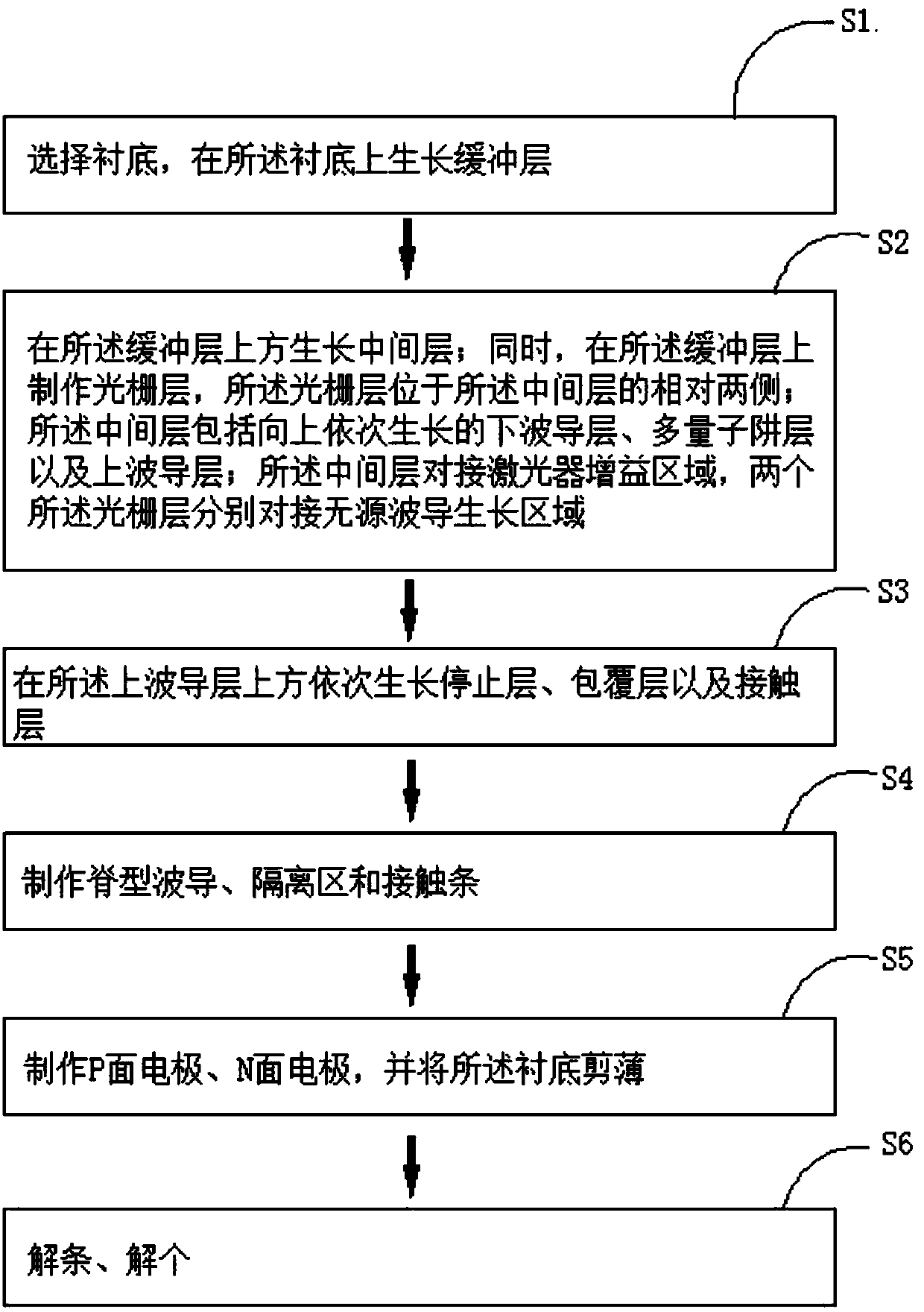

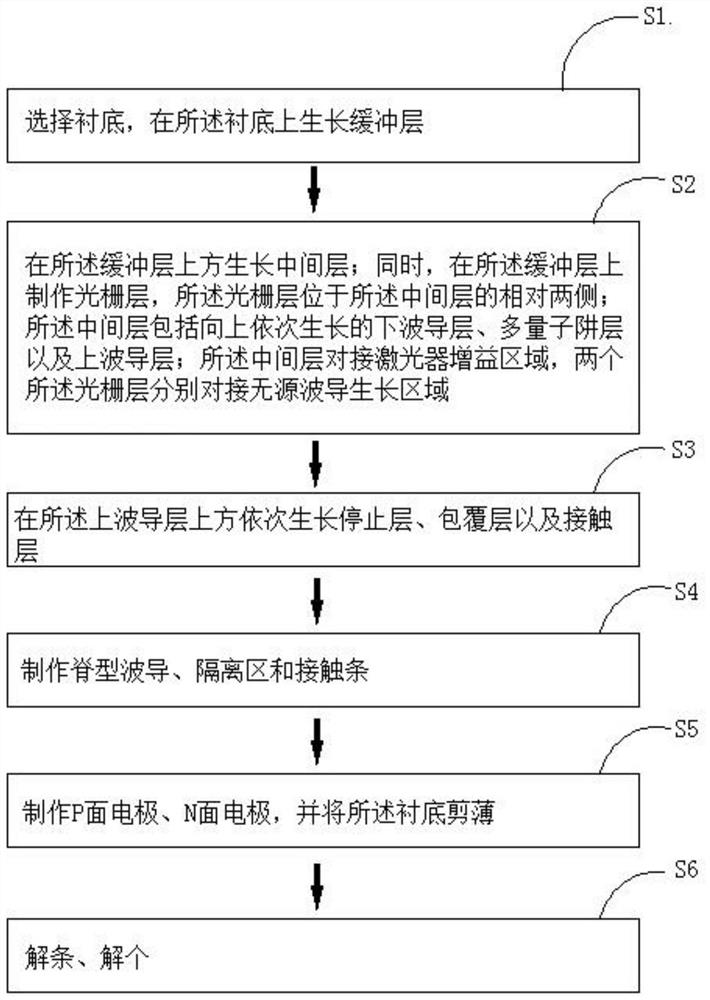

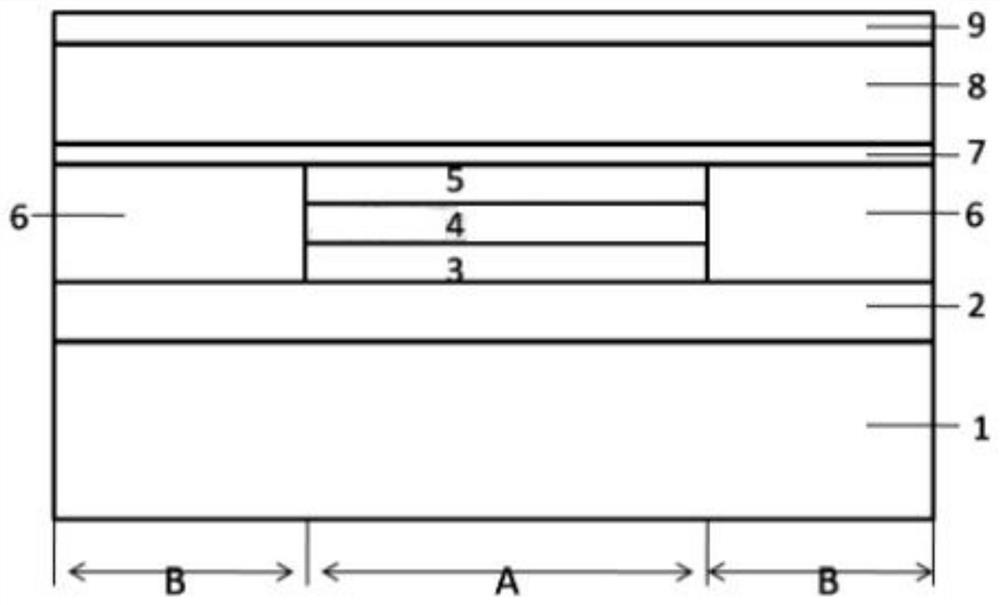

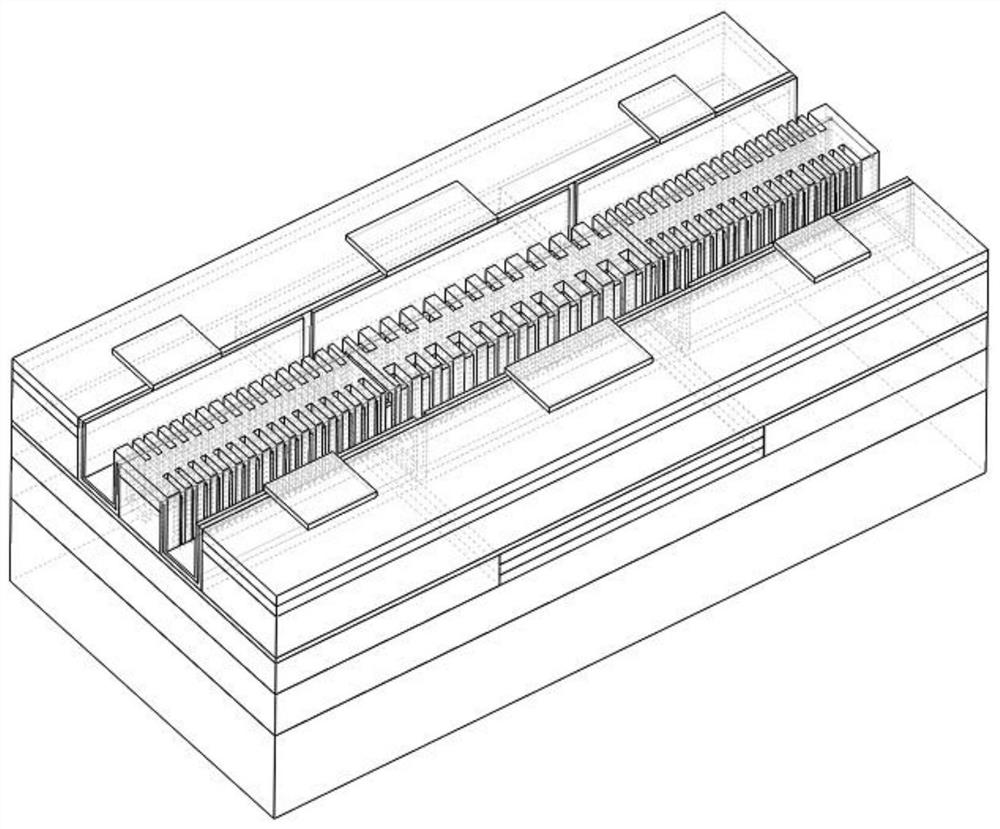

Short-cavity-length surface-emitting laser and manufacturing method thereof

ActiveCN107623250AReduced burial stepsLarge high-speed direct adjustment 3dB bandwidthLaser detailsLaser optical resonator constructionGratingQuantum well

The invention relates to the field of photoelectronic devices and provides a manufacturing method of a short-cavity-length surface-emitting laser. The method comprises the following steps of (S1) selecting a substrate and growing a buffer layer on the substrate; (S2) growing a middle layer at the upper part of the buffer layer, and simultaneously manufacturing grating layers on the buffer layer, wherein the grating layers are located at two opposite sides of the middle layer; and the middle layer comprises a lower waveguide layer, a multi-quantum well layer and an upper waveguide layer which are sequentially grown upwards; the middle layer is docked with a laser gain region; and the two grating layers are docked with passive waveguide growth regions separately; (S3) sequentially growing astop layer, a coating layer and a contact layer at the upper part of the upper waveguide layer; (S4) manufacturing a ridge waveguide, an isolation region and a contact bar; (S5) manufacturing a P surface electrode and an N surface electrode and thinning the substrate; and (S6) splitting the bar and individuals. A segment of passive waveguide region is integrated at each of two sides of the gain region, so that the problem of technological difficulties caused by a small cavity length is solved.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

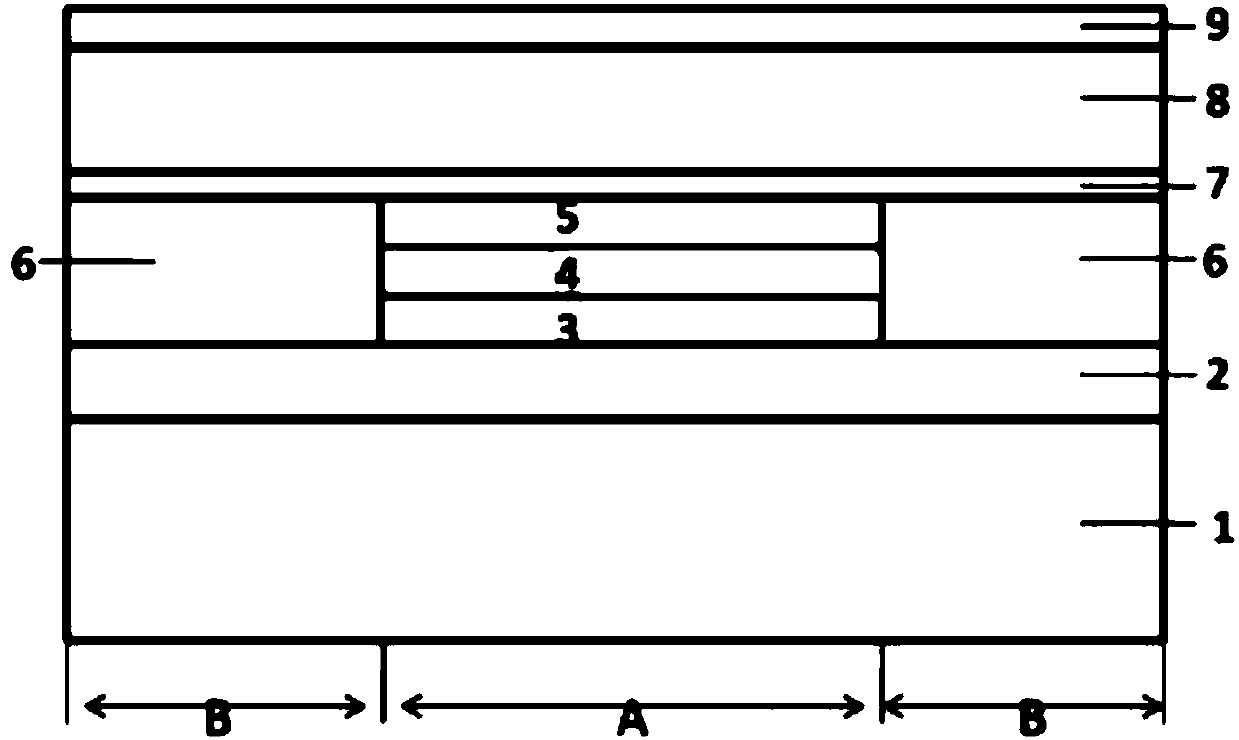

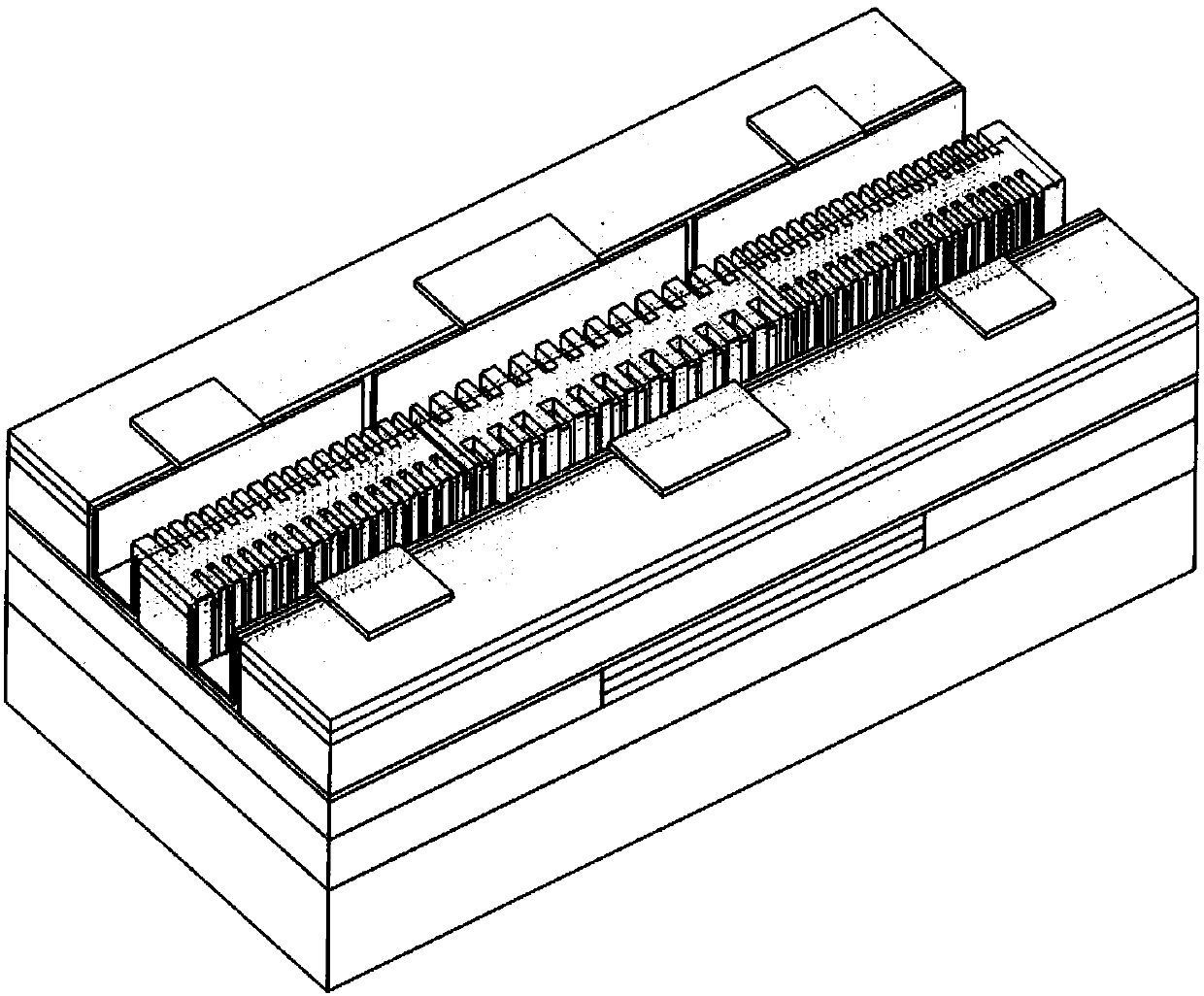

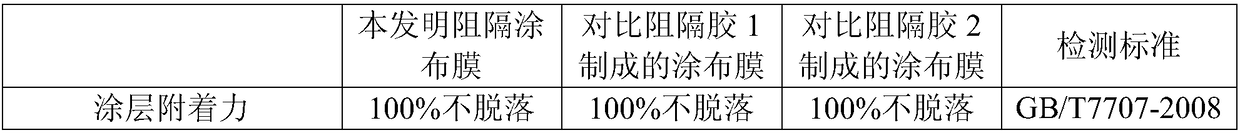

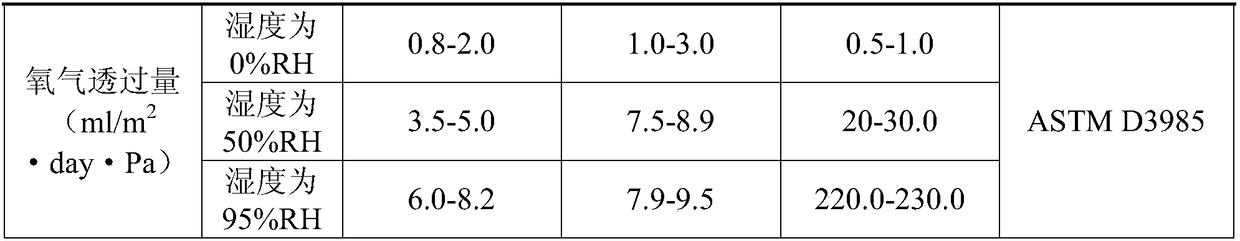

Barrier coating film without prime coat and preparation method thereof

The invention relates to a barrier coating film without a prime coat and a preparation method thereof. By improving barrier coating liquid, a PVOH product having better barrier performance is added inPVDC latex, barrier performance (less than or equal to 2cc / m<2>, 24 hr) is increased, a polymerization technology is adjusted, the barrier coating film without the prime coat is finally prepared, under prerequisite that obstruct effect is good, a film prime coating process is reduced, an organic solvent generated during production can be avoided, and residual risk of a product solvent cannot be generated.

Owner:HAINAN SHINER IND

Process of manufacturing PVC (polyvinyl chloride) type claw type screw cap from film coating iron

The invention discloses a process of manufacturing a PVC (polyvinyl chloride) type claw type screw cap from film coating iron. The process comprises the following concrete steps of selecting PET film coating iron with the thickness being 0.12 to 0.18mm in advance; performing printing at the front side of the double-side PET film coating iron; then, performing glazing coating on the printing surface; next, performing inner coating at the back side of the double-side PET film coating iron. An organic solvent is not used in the production process, the environment-friendly effect is achieved; the film coating iron is used for manufacturing the PVC type claw type screw cap; on one hand, the inner and outer bottom coating process is omitted; the natural gas energy source consumption is reduced; the consumption of paint is greatly reduced through the coating work procedure reduction; the corresponding volatilization and combustion organic solvent quantity is also reduced; the discharge quantity of the organic solvents into the environment can be directly reduced; the film coating iron process has the advantages that the film attachment force, the toughness, the anti-corrosion performance, the deep impact-resistant performance are superior to those of the conventional paint iron; the quality problem of the conventional paint iron due to levelling property, needle holes and the like in the coating process can be solved.

Owner:WUXI HUAPENG BOTTLE CAP

Production method of highlight glass transfer paperboard

ActiveCN105926361AReduce coating processReduce slitting processPaper coatingPaper/cardboardPolyesterPaperboard

The invention discloses a production method of a highlight glass transfer paperboard. The method comprises 1, conveying a paper to a back-coating base through a membrane unrolling base through a compounding machine and instantaneously bonding back coating glue to the back surface of the paper, 2, coating the front surface of a PET polyester blank membrane with highlight high-environmental friendliness resin glue with solid content of 20%, 3, bonding the PET polyester blank membrane with the highlight high-environmental friendliness resin glue and the paper, 4, putting the fully bonded paper on a paper unrolling base of a stripping machine and separating the paper and the PET-based membrane of the PET polyester blank membrane with the highlight high-environmental friendliness resin glue and 5, conveying the separated paper with the highlight high-environmental friendliness resin glue layer into a rolling base and carrying out paper rolling to obtain a paper finished product. The back surface of the paper is coated with the highlight high-environmental friendliness resin glue so that a coating process, an aluminizing process and a membrane finished product slitting process are avoided in membrane preparation and thus a cost is saved for the whole industry. The highlight glass transfer paperboard has high environmental friendliness.

Owner:山东富扬科技包装材料有限公司

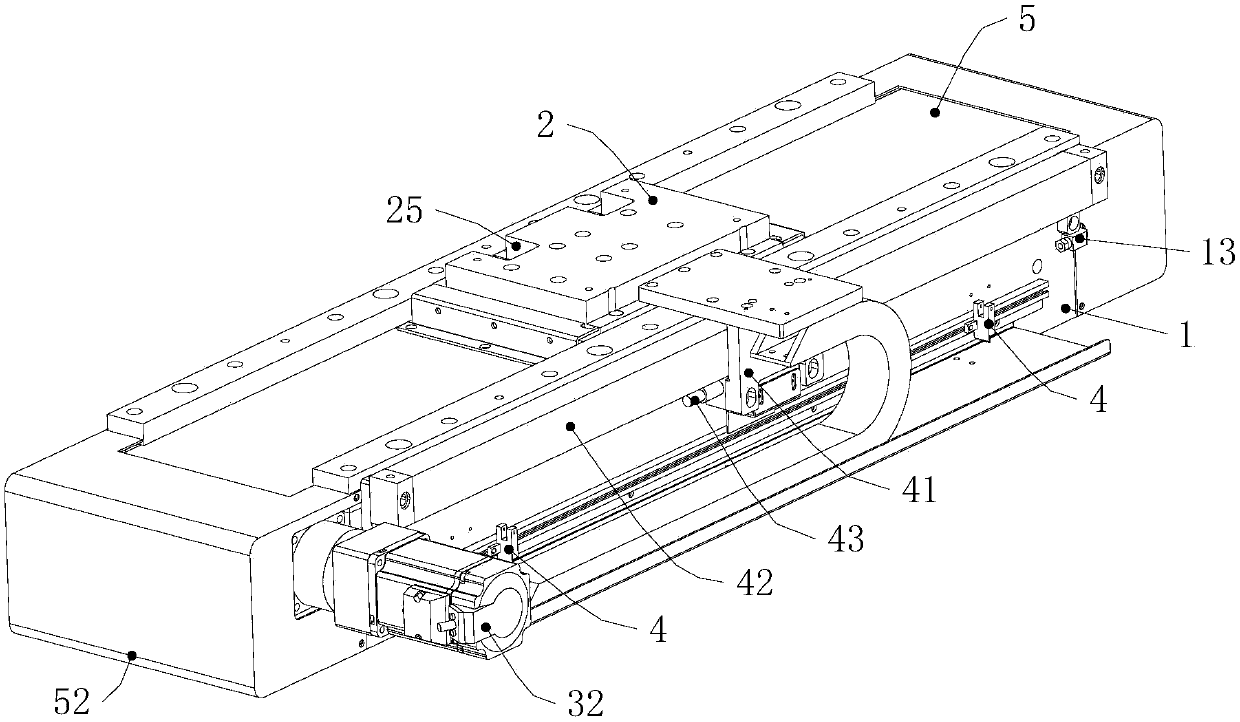

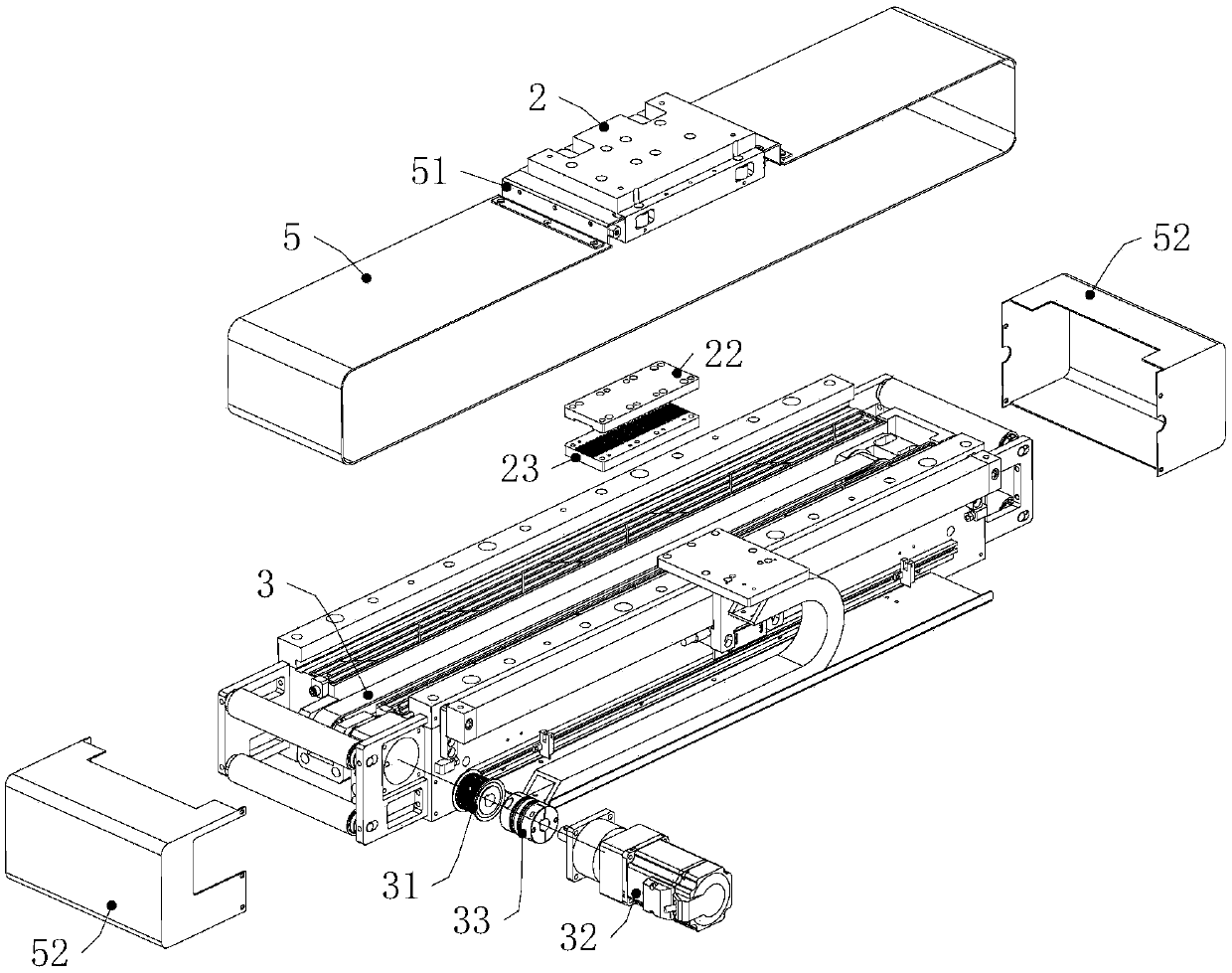

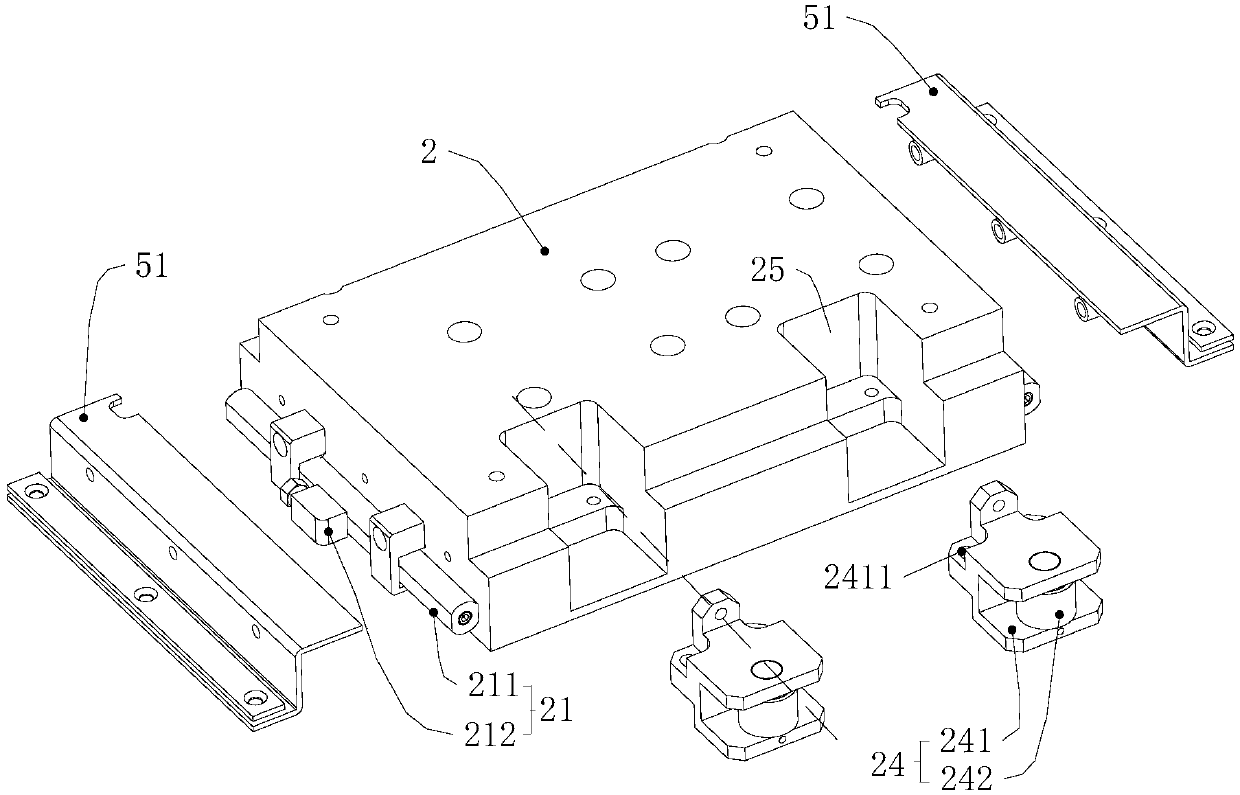

Slide table, coating machine and gluing method

PendingCN110124952AEasy inputEasy outflowPretreated surfacesCoatingsEngineeringMechanical engineering

The invention provides a slide table. The slide table comprises a base and a slide part; the base is provided with a slip part; the slide part is provided with an oil dripping piece; the slip part isprovided with an oil return hole; and lubricating oil dripping from the oil dripping piece flows to the slip part, so that the transverse sliding precision of the slide part on the base is improved. The invention further provides a coating machine; the coating machine comprises a storage tank, a fixture, a mold head, a base plate, a the slide table fixedly connected to the base plate, and a controller; the base plate is provided with a bracket which is assembled with a mold head; the bracket is provided with a lifting mechanism for driving the mold head to ascend or descend; the storage tank is fixedly arranged at the top end of the bracket; and through precise sliding of the slide table, coating liquid is uniform on glued parts, so that the generation of bubbles due to nonuniform coatingof the coating liquid in later procedures is prevented, and the coating quality of the coating liquid is improved. The invention further provides a gluing method; the glued parts are positioned on thefixture, and are calibrated and positioned through a positioning piece; the lifting mechanism is descended, and a gap adjusting mechanism adjusts gaps between the mold head and the glued parts; the slide table moves to a curing device; the coating liquid is coated on the glued parts; and crack outlets are wiped by a wiping mechanism, so that the coating production efficiency and the product quality are improved.

Owner:SHENZHEN MANST TECH CO LTD

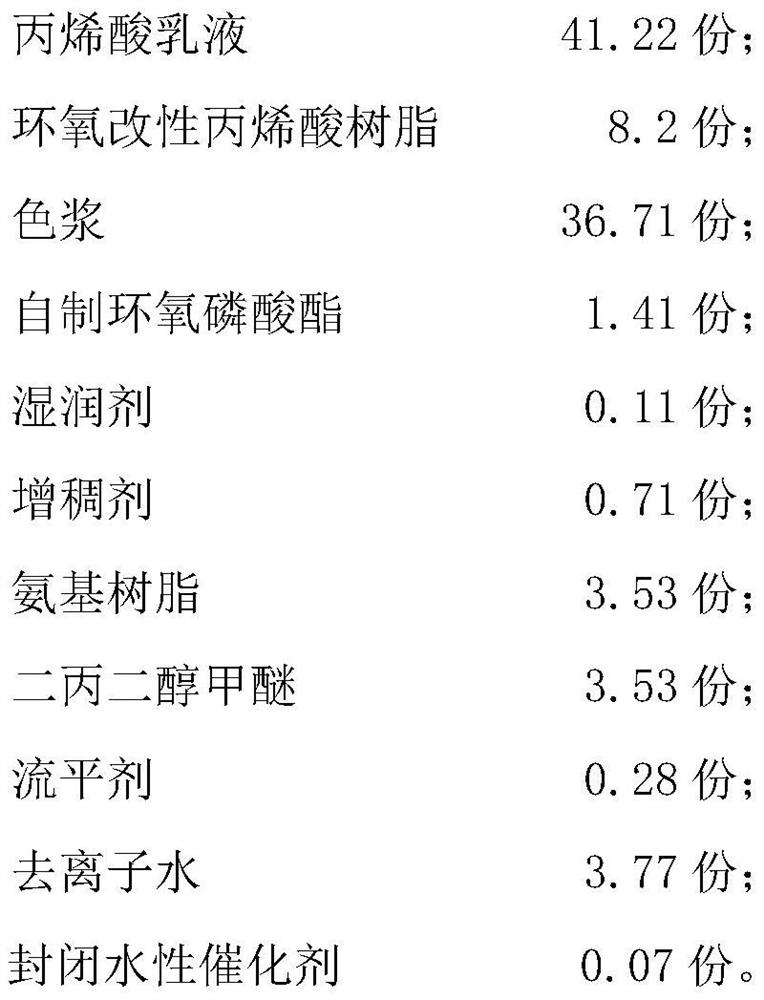

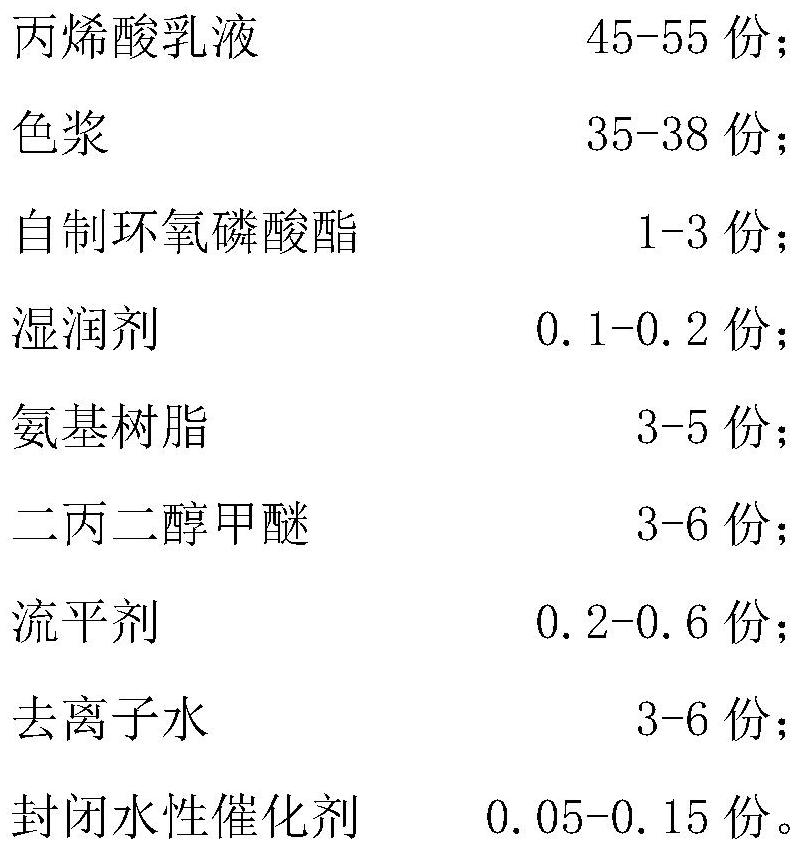

Water-based steel drum coating as well as preparation process and application thereof

ActiveCN113402937AImprove bindingHigh surface flatnessPretreated surfacesEpoxy resin coatingsPtru catalystPhosphate

Owner:SUZHOU SANXIN PACKAGING MATERIAL TECH CO LTD

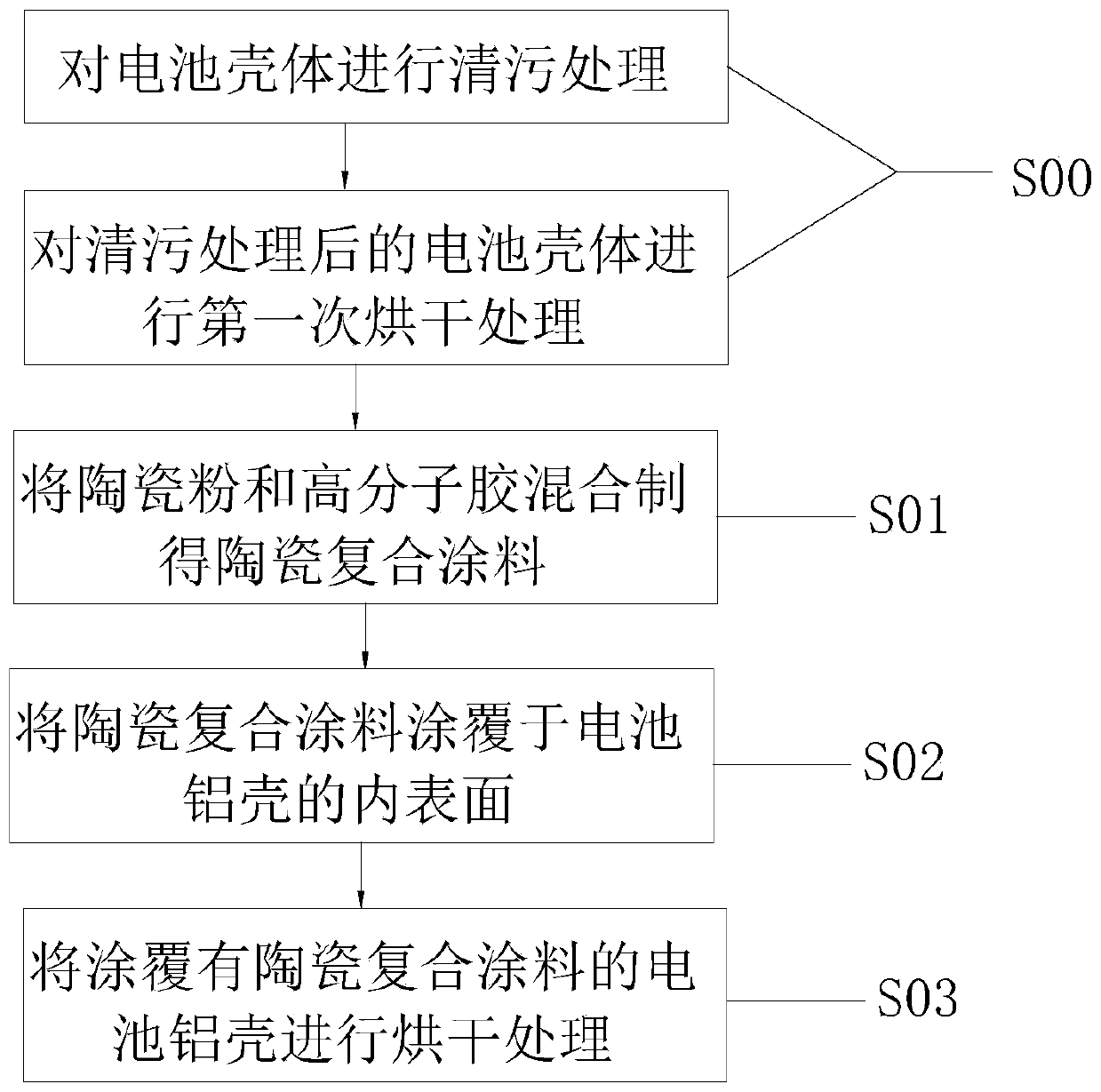

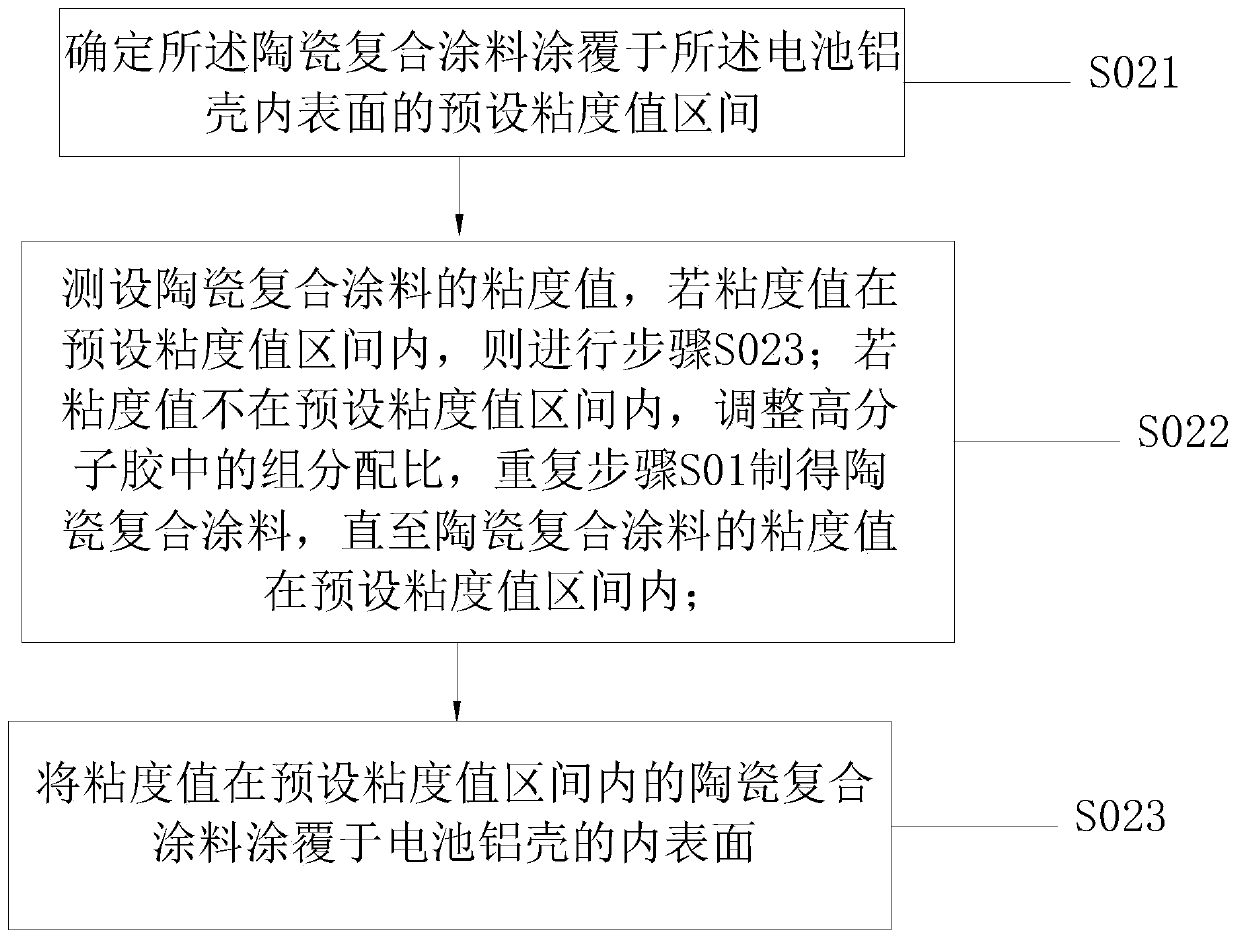

Treatment method of improved lithium ion battery aluminum shell

InactiveCN110931701AImprove thermal conductivityOvercoming the disadvantages of thermal conductivitySecondary cellsJackets/cases materialsCeramic compositeLithium-ion battery

The invention provides a treatment method of an improved lithium ion battery aluminum shell, and belongs to the technical field of lithium batteries. The treatment method solves the problems that an existing Mylar film is thick and occupies a large space, and the problems of over-melting wiredrawing, non-melting falling and the like of a Mylar film which are easily caused because the hot melting effect of the Mylar film is influenced by factors such as temperature, pressure and Mylar film material. The treatment method of the improved lithium ion battery aluminum shell comprises the followingsteps: S01, mixing ceramic powder and polymer glue to prepare a ceramic composite coating; S02, coating the inner surface of the battery aluminum shell with the ceramic composite coating; and S03, drying the battery aluminum shell coated with the ceramic composite coating. The invention has the advantages of good thermal conductivity, capability of saving the internal space of the battery and thelike.

Owner:TIANNENG SAFT ENERGY JOINT CO

Process for manufacturing TPE (thermoplastic elastomer) type claw type screw cap from film coating iron

The invention discloses a process for manufacturing a TPE (thermoplastic elastomer) type claw type screw cap from film coating iron. According to the process, firstly, special film coating iron with the thickness of 0.12 to 0.18 mm is selected in advance; then, the printing is performed at the front side of the special film coating iron; 140 to 170 DEG C baking is performed for 8 to 12 minutes; next, glazing coating is performed on the printing surface; the dry film weight is required to be 5 to 9g / m<2>; the baking is performed at 150 to 190 DEG C for 9 to 13 minutes; then, the iron sheet is subjected to cover punching to manufacture a material falling cover; after the adoption of the special film coating iron, the printing can be directly performed at one surface; the TPE glue particles or glue rings can be directly injected into the other side; the priming coating is not needed at the front side; the paint coating is not needed at the reverse side; the baking combustion energy sources can be saved; the discharge due to organic solvent combustion can also be reduced; the inner and outer bottom coating process is omitted; the natural gas energy source consumption is reduced; on the other hand, the coating work procedures are reduced, so that the consumption of the paint is greatly reduced; the corresponding volatilization and combustion organic solvent quantity is reduced.

Owner:WUXI HUAPENG BOTTLE CAP

A kind of composite plate and its production method

ActiveCN105346172BReduce coating processImprove adhesion stabilitySynthetic resin layered productsLaminationSizingPlastic compounding

The invention discloses a composite panel and a production method thereof. The composite panel comprises a surface layer and a plastic composite base material layer, which are subjected to thermocompression bonding; the production method of the composite panel comprises the following steps: proportionally weighing and mixing PVC powder, heavy calcium and light calcium composite powder, a stabilizer, a flexibilizer, PE wax, an inner lubricant, a plasticizer and an impact modifier, and fully stirring a mixture for mixing; extruding the mixed mixture through an extrusion machine to synthesize a plastic composite base material; bonding the surface layer and the plastic composite base material layer together; finally, cooling, sizing and cutting. According to the adoption of the above technical solution, the plastic composite base material does not use wood powder and can save natural timbers; the surface layer and the plastic composite base material are thermally compressed and bonded together without using glue and without containing formaldehyde, the composite panel is formed by one step and a glue coating process is removed, continuous production is easy to realize, and production efficiency is improved; bonding stability among layers of the composite panel is improved.

Owner:WELLMADE FLOOR IND CO LTD

Brittle capsules for use in tobacco products, methods of manufacture and applications thereof

ActiveCN105536656BImprove brittlenessStay brittleMicroballoon preparationMicrocapsule preparationHigh humidityProcess engineering

The invention relates to a method for manufacturing brittle capsules used in tobacco products. During the second washing process, water consumption, washing times and electrical conductivity are strictly controlled, thereby quantitatively controlling the removal of redundant ions, and finally achieving capsule brittleness. And it can maintain brittleness in high temperature and high humidity environment without coating. The present invention also includes the crisp capsules for tobacco products prepared according to the method and the application thereof.

Owner:CHINA TOBACCO GUIZHOU IND

A method for forming a two-color and double-textured PVD film layer on a metal substrate and the metal substrate obtained therefrom

ActiveCN108239745BStrong adhesionImprove wear resistanceVacuum evaporation coatingSputtering coatingSand blastingPrinting ink

Owner:BYD CO LTD

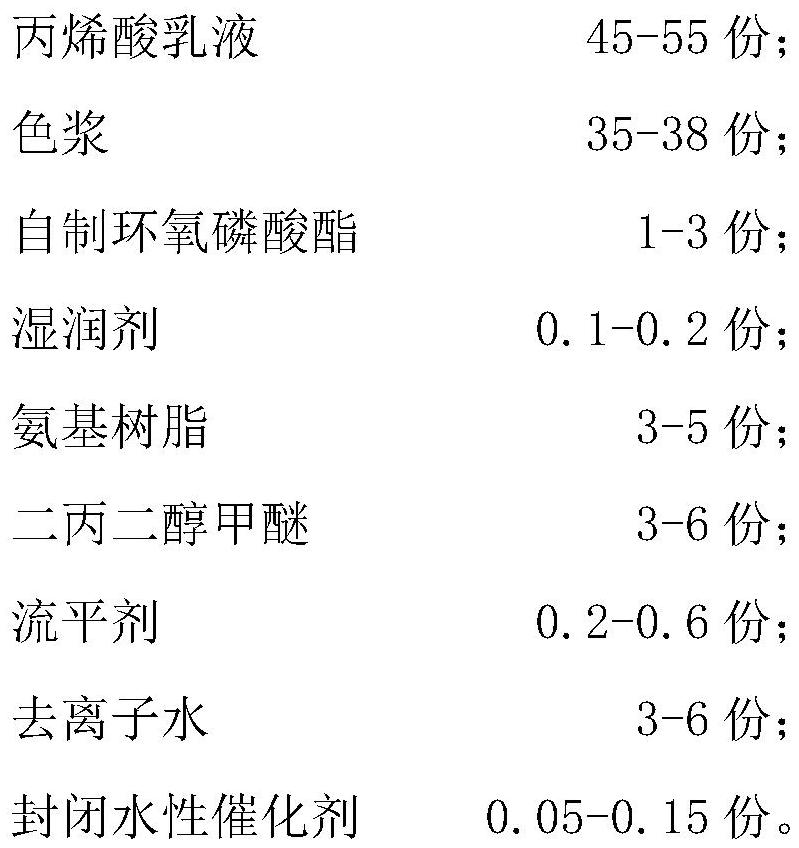

A kind of water-based steel drum paint, preparation process and use

ActiveCN113402937BImprove bindingHigh surface flatnessPretreated surfacesEpoxy resin coatingsPolymer sciencePtru catalyst

The invention discloses a water-based steel drum coating, a preparation process and an application. The water-based steel drum coating at least comprises acrylic emulsion, color paste, self-made epoxy phosphate, wetting agent, amino resin, dipropylene glycol methyl ether, fluid Leveling agent, deionized water, and blocked aqueous catalyst. After the water-based steel drum paint in this scheme is formed into a film, the bonding force between the films is good, the surface flatness is high, and there will be no defects such as bubbles and fluidity. It can be directly applied after the first coating without baking The second layer of coating is applied to reduce the coating process. At the same time, the coating has high wear resistance, cooking resistance and adhesion after film formation, which can effectively protect the surface of the steel drum from damage.

Owner:SUZHOU SANXIN PACKAGING MATERIAL TECH CO LTD

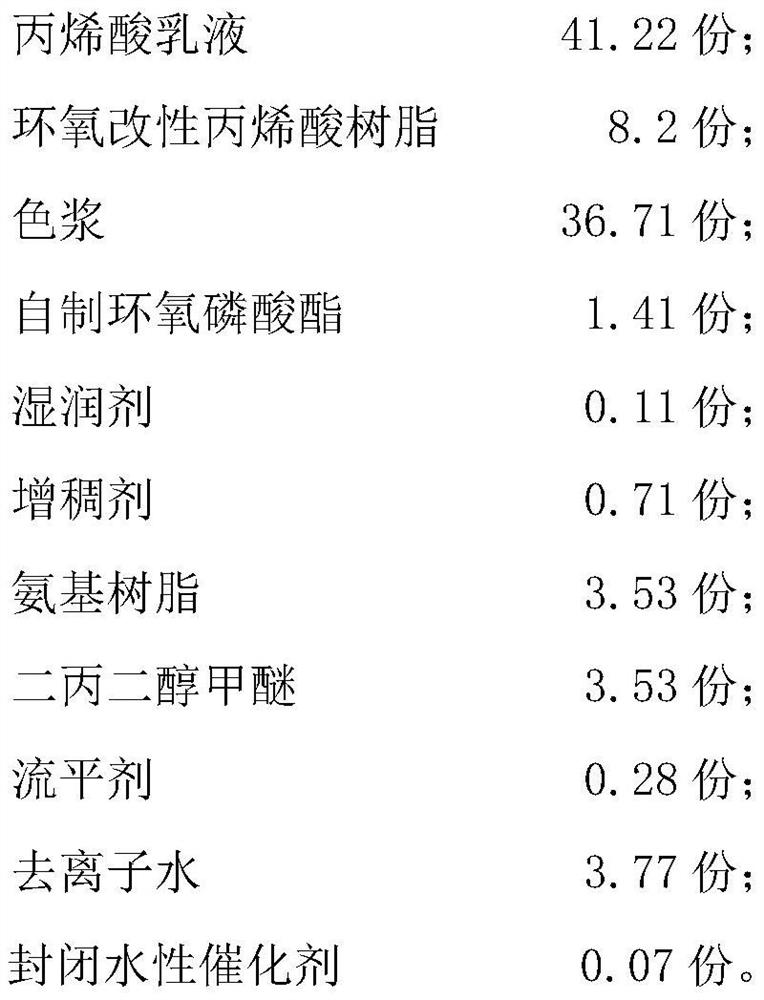

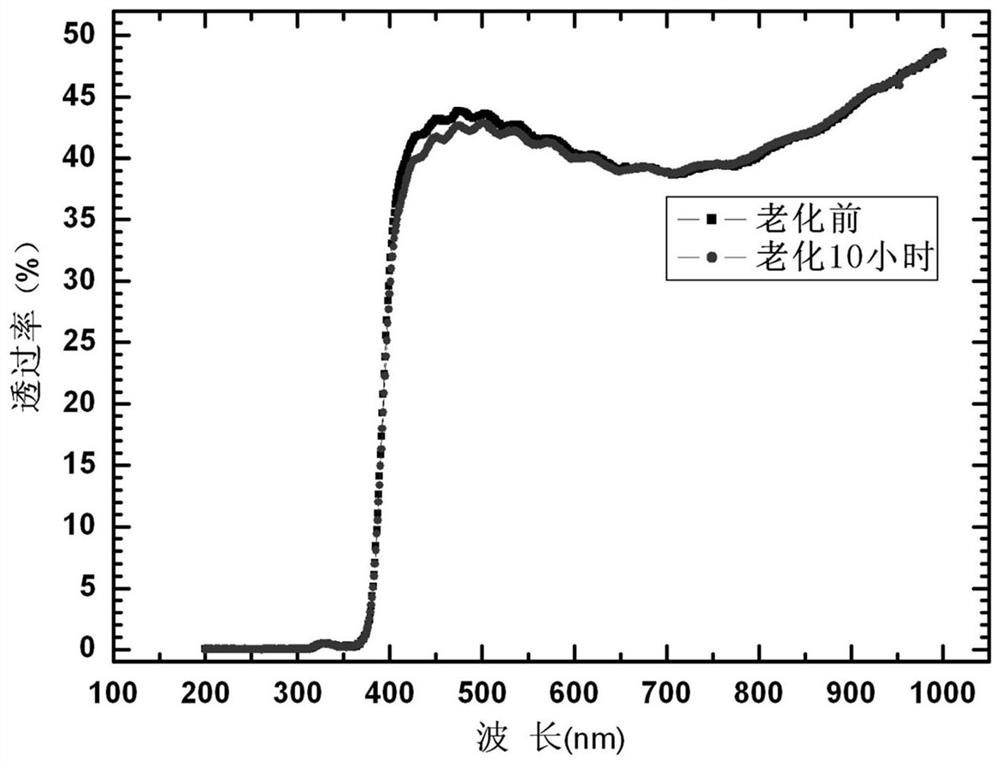

Single-layer low-permeability inorganic nano-heat insulation film with high weather resistance and high definition and preparation method thereof

ActiveCN110760273BGood weather resistanceImprove clarityNon-macromolecular adhesive additivesSynthetic resin layered productsUv absorbanceWeather resistance

The invention discloses a single-layer low-permeability inorganic nano heat insulation film with high weather resistance and high definition and its preparation method. A layered structure composed of treated PET base film, installation adhesive layer coated with installation adhesive coating and release film; UV curing coating includes inorganic pigment slurry, UV curing resin, photosensitizer and solvent, etc.; inorganic pigment slurry In addition to dispersant and solvent, the material also includes at least one inorganic pigment with low ultraviolet absorption rate, and the installation glue coating can also have inorganic pigment slurry in addition to ultraviolet absorber, pressure-sensitive adhesive and solvent. UV-curable resins, pressure-sensitive adhesives, and solvents must be compatible with dispersants. In the present invention, through the combination of low ultraviolet absorption inorganic pigments, dispersants and photosensitizers, a single-layer thermal insulation film with high weather resistance and high definition is realized by UV curing and film formation, and the thermal insulation film is completed through two coating processes. The production of hot film greatly reduces the production cost.

Owner:SUZHOU GENER NANO TECH

A short cavity long surface emitting laser and its manufacturing method

ActiveCN107623250BReduced burial stepsLarge high-speed direct adjustment 3dB bandwidthLaser detailsLaser optical resonator constructionGratingEngineering

The present invention relates to the field of optoelectronic devices, and provides a method for manufacturing a short cavity long surface emitting laser, comprising the following steps: S1, select a substrate, and grow a buffer layer on the substrate; S2, grow on the buffer layer Intermediate layer; meanwhile, fabricate a grating layer on the buffer layer, the grating layer is located on opposite sides of the intermediate layer; the intermediate layer includes a lower waveguide layer, a multi-quantum well layer and an upper waveguide layer that grow upwards in sequence ; The middle layer is connected to the laser gain region, and the two grating layers are respectively connected to the passive waveguide growth region; S3, sequentially growing a stop layer, a cladding layer and a contact layer above the upper waveguide layer; S4, making a ridge waveguide, isolation region and contact strip; S5, making P-face electrode and N-face electrode, and cutting the substrate thin; S6, stripping and stripping. The invention integrates a passive waveguide area on both sides of the gain area, which solves the problem of difficult process caused by the small cavity length.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

Production method of high-gloss glass transfer cardboard

ActiveCN105926361BReduce coating processReduce slitting processPaper coatingPaper/cardboardPolyesterPaperboard

The invention discloses a production method of a highlight glass transfer paperboard. The method comprises 1, conveying a paper to a back-coating base through a membrane unrolling base through a compounding machine and instantaneously bonding back coating glue to the back surface of the paper, 2, coating the front surface of a PET polyester blank membrane with highlight high-environmental friendliness resin glue with solid content of 20%, 3, bonding the PET polyester blank membrane with the highlight high-environmental friendliness resin glue and the paper, 4, putting the fully bonded paper on a paper unrolling base of a stripping machine and separating the paper and the PET-based membrane of the PET polyester blank membrane with the highlight high-environmental friendliness resin glue and 5, conveying the separated paper with the highlight high-environmental friendliness resin glue layer into a rolling base and carrying out paper rolling to obtain a paper finished product. The back surface of the paper is coated with the highlight high-environmental friendliness resin glue so that a coating process, an aluminizing process and a membrane finished product slitting process are avoided in membrane preparation and thus a cost is saved for the whole industry. The highlight glass transfer paperboard has high environmental friendliness.

Owner:山东富扬科技包装材料有限公司

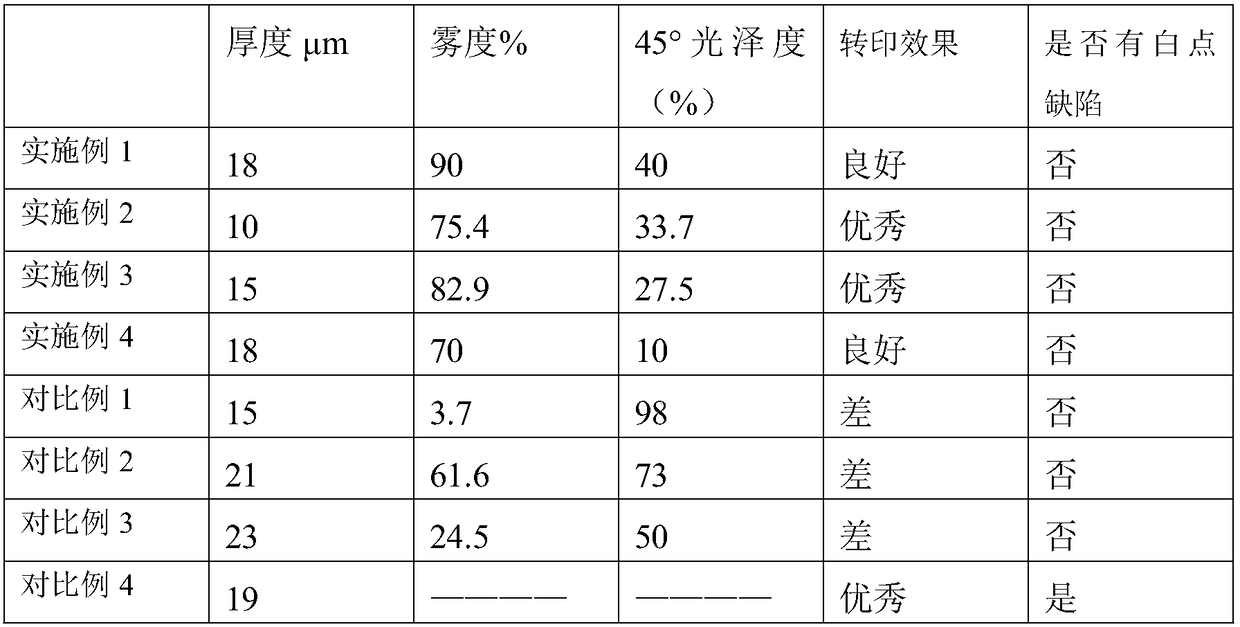

A kind of matte polyester film for fabric cold transfer printing and its preparation method and application

ActiveCN107141734BThe overall thickness is thinHigh hazeTransfer printing processFlat articlesPolyesterSilicon oxide

The invention relates to a matt polyester thin film for fabric cold transfer printing, and a preparation method and application thereof. The matt polyester thin film is mainly prepared from the following raw materials in percentage by mass: 20 to 80 percent of silicon series polyester slices, 0.1 to 40 percent of full-dull polyester slices, 10 to 40 percent of waste and old polyester material regeneration particles and 5 to 50 percent of bright polyester slices, wherein the mass content of silicon oxide in the silicon series polyester slices is 3000 to 12000mg / kg; the particle size range of the silicon oxide is 2 to 10mu m; the mass percent content of titanium oxide in the full-dull polyester slices is 2.0 to 3.0 percent. The matt polyester thin film has the advantages that the thickness is thin; the haze degree is high; the glossiness is low; the matt polyester thin film is used as a transfer printing carrier in the fabric cold transfer printing process; the transfer printing effect is good; inevitable printing white dots of a traditional transfer printing carrier cannot occur; meanwhile, the preparation method is simple and convenient; the raw material sources are wide; the matt film does not need the subsequent coating coating process; the redundant coating technological process is reduced; the cost is reduced.

Owner:YIHUA TORAY POLYESTER FILM CO LTD

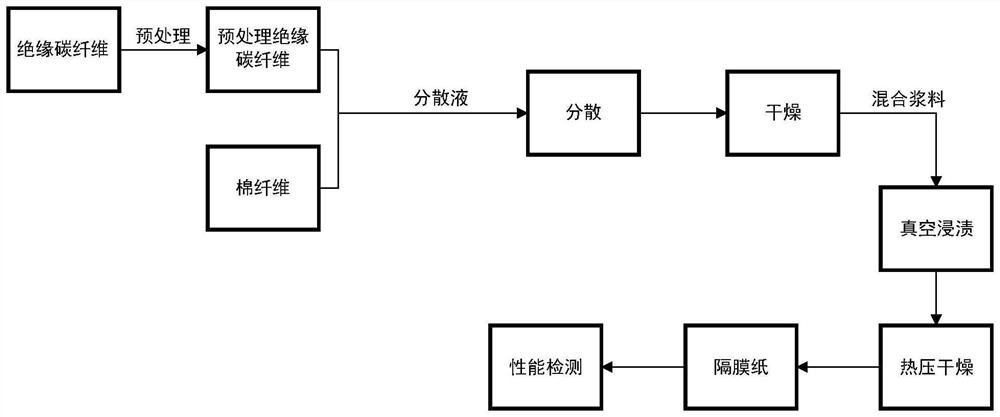

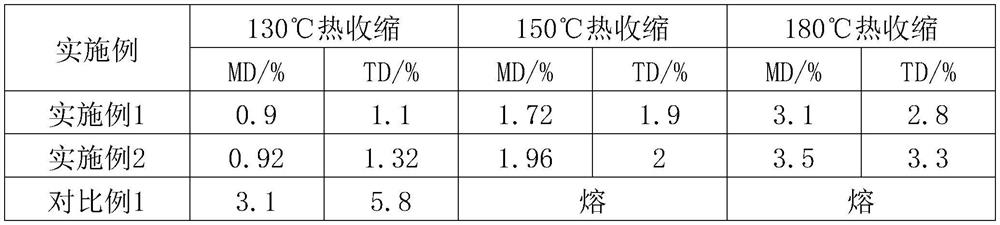

High-temperature-resistant diaphragm paper for lithium ion battery and preparation method thereof

InactiveCN114744366AImprove securityExtended service lifeFinal product manufactureCell component detailsElectrolytic agentCarbon fibers

The invention belongs to the technical field of lithium ion batteries, and particularly relates to high-temperature-resistant diaphragm paper for a lithium ion battery and a preparation method of the high-temperature-resistant diaphragm paper. Wherein the mixed fiber matrix comprises insulating carbon fibers and cotton fibers; the inorganic powder particles are loaded on the surface of the mixed fiber matrix; according to the high-temperature-resistant diaphragm paper for the lithium ion battery, the mixed fibers with excellent high-temperature resistance and excellent mechanical performance are adopted, battery short circuit caused by lithium dendrite puncture can be effectively avoided, the safety performance of the lithium ion battery is improved, and the service life of the lithium ion battery is prolonged. The prepared diaphragm paper contains the inorganic powder particles, so that the mechanical property and the heat resistance of the diaphragm paper are further improved, the affinity of the diaphragm paper and electrolyte is improved, meanwhile, the coating procedure is omitted through direct vacuum impregnation of the mixed fibers and the inorganic powder particles, the efficiency is improved, and the production cost is reduced. And the problem that inorganic powder particles fall off in the using process is also solved.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

Fiber-based wall decoration material

InactiveCN110128905AEasy to useRealize high-value recyclingFireproof paintsAntifouling/underwater paintsCalcium alginateNatural fiber

The invention discloses a fiber-based wall decoration material which comprises the following raw materials in parts by weight: 2-4 parts of calcium alginate, 6-8 parts of shell powder, 20-30 parts ofa SiO2 supported tourmaline / TiO2 compound, 100-130 parts of modified natural fiber, 4-7 parts of aminosilane, 1-2 parts of ammonium persulfate, 4-6 parts of coumarone gum and 20-30 parts of acrylamide. By selecting calcium alginate, shell powder and other self-flame-retardant and self-mildew-proof materials, the use of non-natural biocompatible materials is reduced, so that the affinity of the wall coating product is improved.

Owner:LIMING VOCATIONAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com