Single-layer low-permeability inorganic nano-heat insulation film with high weather resistance and high definition and preparation method thereof

An inorganic nanometer, high-definition technology, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problems of high production cost, low infrared blocking rate, low definition, etc., and achieves UV resistance and high temperature resistance. Stability, low visible light transmittance, the effect of ensuring weather stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

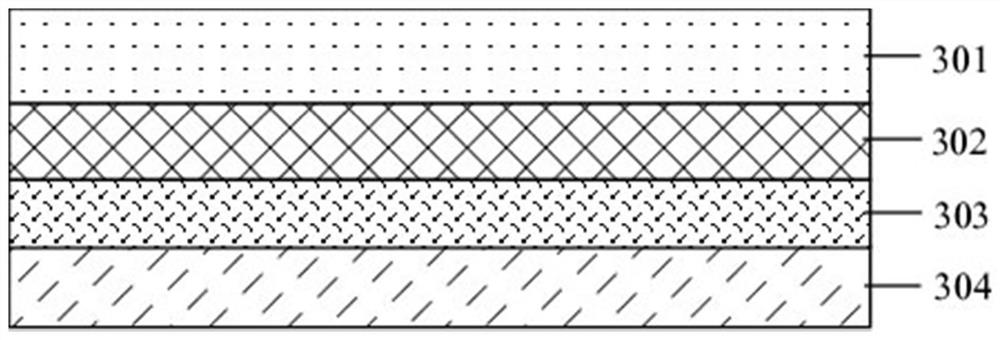

[0049] The preparation method of the above-mentioned single-layer low-permeability inorganic nano-heat insulation film specifically includes the following steps:

[0050] S1, release film selection: select a 23μm thick PET film, one side of which is coated with release silicone oil, and its peel strength is 15-30 g / inch;

[0051] S2, base film selection: select a piece of transparent PET which has been precoated and corona treated on both sides, and the haze is less than 1% as the base film, and the precoated precoat is PU precoat;

[0052] S3, preparation of inorganic nano-pigment slurry: first mix and stir the dispersant and solvent in the pre-mixing tank, then pass it into the grinding chamber of the ball mill for grinding, and gradually add silicon nitride titanium or carbon black, and obtain nitrided pigments after grinding. Silicon titanium slurry or carbon black slurry;

[0053] S4, preparation of UV-curable coating: first add the solvent into the mixing tank, then add...

Embodiment 1

[0058] Release film selection: Select a silicone oil release film with a release force of 20 g / inch.

[0059] Base film selection: select a 38 μm thick PET base film with a haze of less than 1%, and its longitudinal and transverse thermal shrinkage rates are 1.2% and 0.2% respectively. The base film is corona treated on one side and pre-coated with PU on the other side.

[0060]Preparation of silicon nitride titanium slurry: Weigh 10 parts of silicon nitride titanium with a particle size of 20nm (the doping ratio of silicon is 5%), 2 parts of a small molecule dispersant with a molecular weight of 800, and a polymer dispersion with a molecular weight of 5000. 7 parts of dispersant and 81 parts of ethyl acetate, first mix the dispersant and solvent in the premix tank for 15 minutes, then gradually add silicon nitride titanium, stir at 500RPM for 30 minutes, and finally circulate into 8 Grinding in the grinding chamber of a ball mill, with a linear speed of 10 m / s, after 36 hour...

Embodiment 2

[0067] Preparation of UV-curable coating: Weigh 6.55 parts of silicon nitride titanium slurry, 6.55 parts of carbon black slurry, 32.32 parts of hexafunctional aliphatic polyurethane acrylic resin with a molecular weight of 1000, silicon-modified copolymer flow 0.42 parts of leveling agent, 0.75 parts of 2-hydroxy-2-methyl-1-phenylacetone, 0.49 parts of 2-hydroxy-2-methyl-1-phenylacetone, 0.49 parts of phenyl bis(2,4,6-tri 0.46 parts of methylbenzoyl)phosphine oxide and 52.46 parts of ethyl acetate. First add the solvent to the mixing tank, then add silicon nitride titanium slurry and carbon black slurry respectively, stir at 300RPM for 5 minutes, then add the rest of the materials, stir at 500RPM for 30 minutes to obtain the required UV Light-curing coatings.

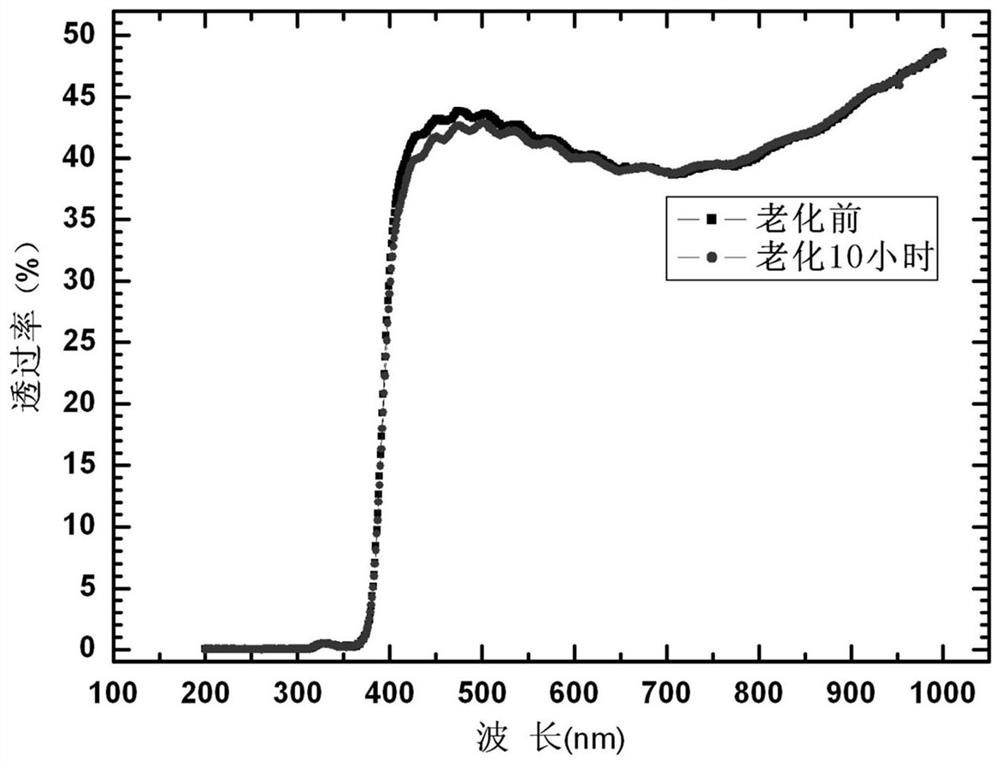

[0068] In Example 2, except for the UV-curable coating, other coatings and materials are the same as in Example 1. Sample 2 was prepared by the same method as described in Example 1. The carbon black content of samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com