High-temperature-resistant diaphragm paper for lithium ion battery and preparation method thereof

A lithium-ion battery and separator paper technology, which is applied in the direction of secondary batteries, battery pack parts, secondary battery repair/maintenance, etc., can solve the problem of easy falling off of inorganic powder, save the coating process and improve safety Performance and service life, effects of improving mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

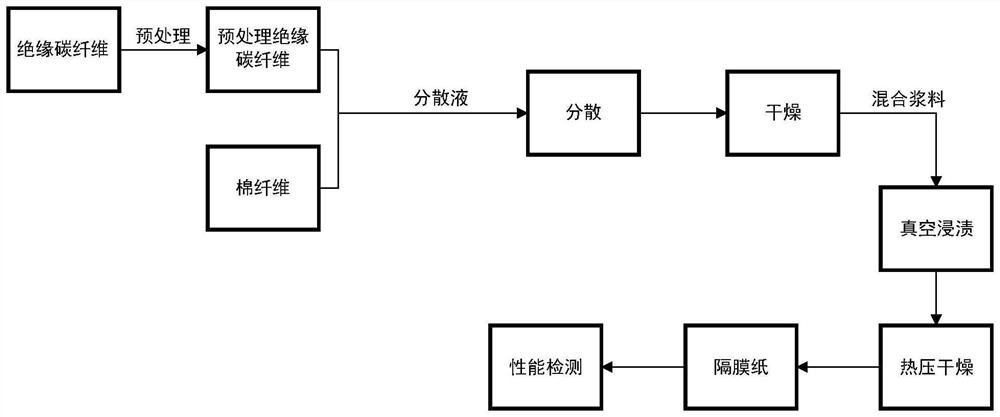

[0014] like figure 1 As shown, the present invention also provides a method for preparing high temperature resistant diaphragm paper for lithium ion batteries, comprising the following steps: step S1, respectively preparing a diaphragm paper substrate and a mixed slurry; step S2, using a vacuum impregnation method to prepare the mixed slurry The material is loaded onto the substrate of the separator paper, and then hot-pressed and dried to obtain a high-temperature resistant separator paper for lithium ion batteries.

[0015] In this embodiment, specifically, the preparation of the diaphragm paper substrate in step S1 includes: weighing an appropriate amount of insulating carbon fiber, adding it to a 3 mol / L sodium hydroxide alkaline aqueous solution, pre-processing, and then adding distilled water to the insulating carbon fiber Suction filtration, wash to neutrality, and dry; make the dispersant into a dispersion of a certain concentration, weigh an appropriate amount of insu...

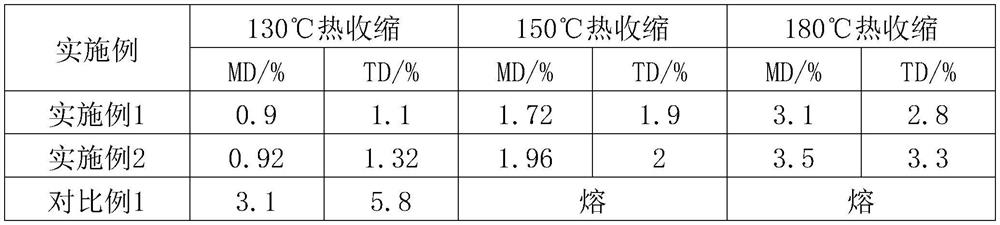

Embodiment 1

[0024] Weigh 0.3 g of insulating carbon fiber, add it to 500 mL of 3 mol / L sodium hydroxide alkaline aqueous solution, pretreat for 3 min, and then filter the insulating carbon fiber with distilled water until it is neutral, and dry. Polyacrylamide (PAM) was dissolved in water by stirring to make a dispersion with a concentration of 3wt%. The mass of the dispersion was 1kg. The pretreated insulating carbon fiber and 0.1g cotton fiber were added to the dispersion. The dispersing machine is used for dispersing and dispersing. After the fibers are uniformly dispersed, the fiber dispersion is poured into the paper machine, the dispersion is filtered off, and dried in an oven at 70°C to obtain a membrane paper matrix.

[0025] 20 g of phenolic resin, 40 g of alumina, and 2 g of curing agent were added to 138 g of ethanol solution, and stirred evenly to obtain a mixed slurry. Put the membrane paper substrate into the vacuum impregnation kettle, adjust it to a negative pressure state...

Embodiment 2

[0027] Weigh 0.2 g of insulating carbon fiber, add it to 500 mL of 3 mol / L sodium hydroxide alkaline aqueous solution, pre-treat for 3 min, and then filter the insulating carbon fiber with distilled water until it is neutral, and dry. Dissolve PE0 in water by stirring to make a dispersion with a concentration of 5wt%, the mass of the dispersion is 1kg, add the pretreated insulating carbon fiber and 0.2g cotton fiber into the dispersion, and use a fiber dispersing machine to disperse and disperse. , after the fibers are evenly dispersed, the fiber dispersion is poured into a paper machine, the dispersion is filtered off, and dried in an oven at 70°C to obtain a membrane paper matrix.

[0028] 20 g of phenolic resin, 40 g of alumina, and 2 g of curing agent were added to 138 g of ethanol solution, and stirred evenly to obtain a mixed slurry. Put the membrane paper substrate into the vacuum impregnation kettle, adjust it to a negative pressure state, pump the mixed slurry into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com