Method for growing graphene on Si/C composite material, material obtained through such method, and application of such material

A composite material, graphene technology, applied in the direction of graphene, electrical components, battery electrodes, etc., can solve the problems of graphene surface pollution, poor high-rate charge-discharge performance, complex transfer process, etc., to improve electrochemical performance. , Improve the charging rate and reduce the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

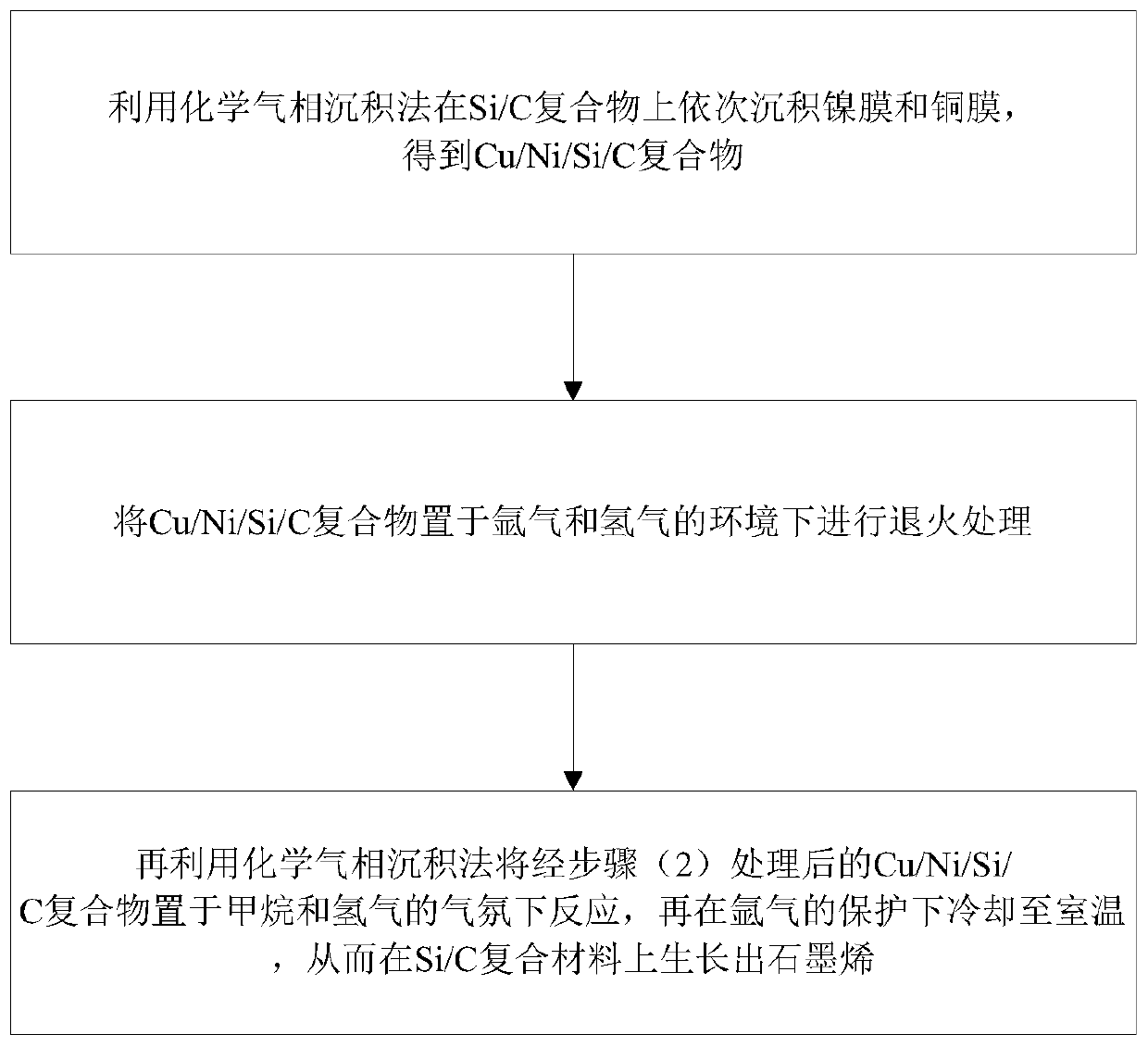

[0047] S1. A nickel film and a copper film are sequentially deposited on the Si / C composite using a chemical vapor deposition method to obtain a Cu / Ni / Si / C composite. This step specifically includes:

[0048] Put the Si / C composite into the reaction chamber, evacuate and heat to 130°C at the same time;

[0049] Into the argon gas, then into the gaseous nickel carbonyl to deposit the nickel film.

[0050] After the nickel film is deposited, continue to pass argon into the reaction chamber, heat to 330°C under the condition of continuous argon, and pass hydrogen and copper chloride vapor to deposit the copper film.

[0051] S2. The Cu / Ni / Si / C composite is annealed in an argon and hydrogen environment. The annealing conditions are as follows: the first annealing stage: the annealing temperature is 920°C, and the annealing time is 5 hours; the second annealing stage: the annealing temperature is 1050°C, and the annealing time is 25 hours.

[0052] S3. The Cu / Ni / Si / C composite treated by S...

Embodiment 2

[0054] S1. A nickel film and a copper film are sequentially deposited on the Si / C composite using a chemical vapor deposition method to obtain a Cu / Ni / Si / C composite. This step specifically includes:

[0055] Put the Si / C composite into the reaction chamber, evacuate and heat to 120°C at the same time;

[0056] Into the argon gas, then into the gaseous nickel carbonyl to deposit the nickel film.

[0057] After the nickel film is deposited, continue to pass argon into the reaction chamber, heat to 300°C under the condition of continuously passing argon, and pass hydrogen and copper chloride vapor to deposit the copper film at the same time.

[0058] S2. The Cu / Ni / Si / C composite is annealed in an argon and hydrogen environment. The annealing conditions are as follows: the first annealing stage: the annealing temperature is 900°C, and the annealing time is 10 hours; the second annealing stage: the annealing temperature is 1100°C, and the annealing time is 20 hours.

[0059] S3. The Cu / Ni...

Embodiment 3

[0061] S1. A nickel film and a copper film are sequentially deposited on the Si / C composite using a chemical vapor deposition method to obtain a Cu / Ni / Si / C composite. This step specifically includes:

[0062] Put the Si / C composite into the reaction chamber, evacuate and heat to 150°C at the same time;

[0063] Into the argon gas, then into the gaseous nickel carbonyl to deposit the nickel film.

[0064] After the nickel film is deposited, continue to pass argon into the reaction chamber, and heat to 350°C under the condition of continuously passing argon, while passing hydrogen and copper chloride vapor to deposit the copper film.

[0065] S2. The Cu / Ni / Si / C composite is annealed in an argon and hydrogen environment. The annealing conditions are as follows: the first annealing stage: the annealing temperature is 950°C, the annealing time is 2 hours; the second annealing stage: the annealing temperature is 1000°C, the annealing time is 30 hours.

[0066] S3. The Cu / Ni / Si / C composite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com