Light diffusing polyester film

A technology of polyester film and light diffusion, applied in the field of materials, to achieve high light transmittance, avoid environmental pollution, and sufficient optical diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

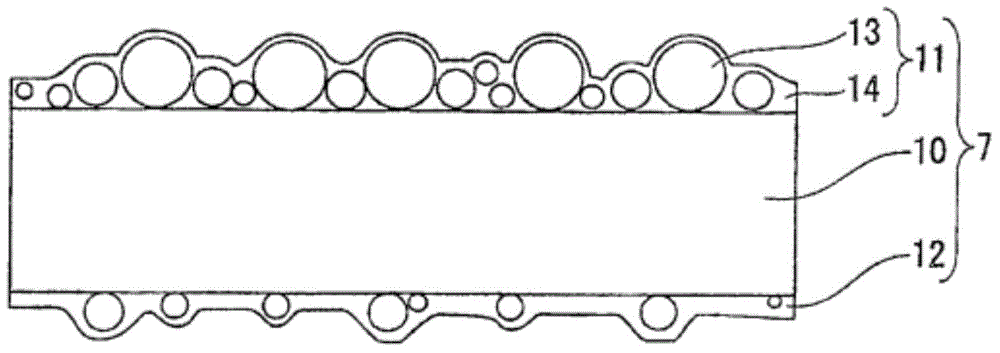

Image

Examples

Embodiment 1

[0030] Surface layer: 25% Yizheng chemical fiber FG610, 75% Yizheng chemical fiber SB500

[0031] Middle layer: 5% PP, 10% Changzhou Lucky LK7020 (2.5% silicon dioxide mass ratio, particle size about 4um), 85% Yizheng chemical fiber SB500

[0032] The properties of the optical diffusion film prepared after biaxial stretching and heat setting are shown in Table 1.

Embodiment 2

[0034] Surface layer: 15% Shanghai Lianle MB40 (silica mass ratio content 40%, particle size about 5-6um), 75% Yizheng chemical fiber SB500

[0035] Middle layer: 3% PP, 97% Yizheng chemical fiber SB500

[0036] The properties of the optical diffusion film prepared after biaxial stretching and heat setting are shown in Table 1.

Embodiment 3

[0038] Surface layer: 30% Shanghai Lianle MB40 (silica mass ratio content 40%, particle size about 5-6um), 75% Yizheng chemical fiber SB500

[0039] Middle layer: 3% PP, 97% Yizheng chemical fiber SB500

[0040] The properties of the optical diffusion film prepared after biaxial stretching and heat setting are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com