Enhanced optical fiber cloth liner for artificial transparent stone and preparation method of enhanced optical fiber cloth liner

An enhanced, optical fiber technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of unfavorable light collection, discontinuous luminescence, poor bonding force, etc., and achieve good randomness, natural and continuous luminous shape, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

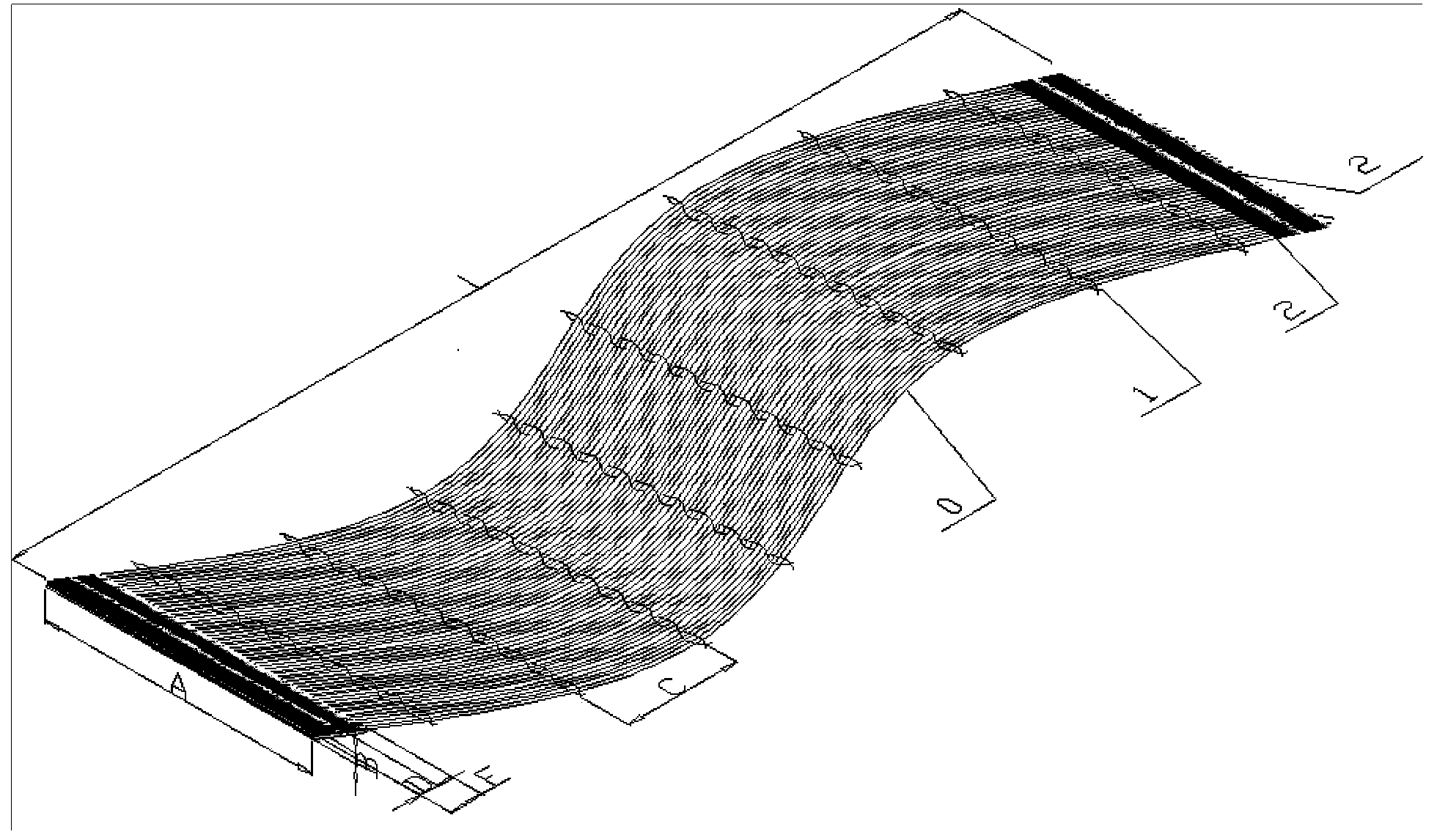

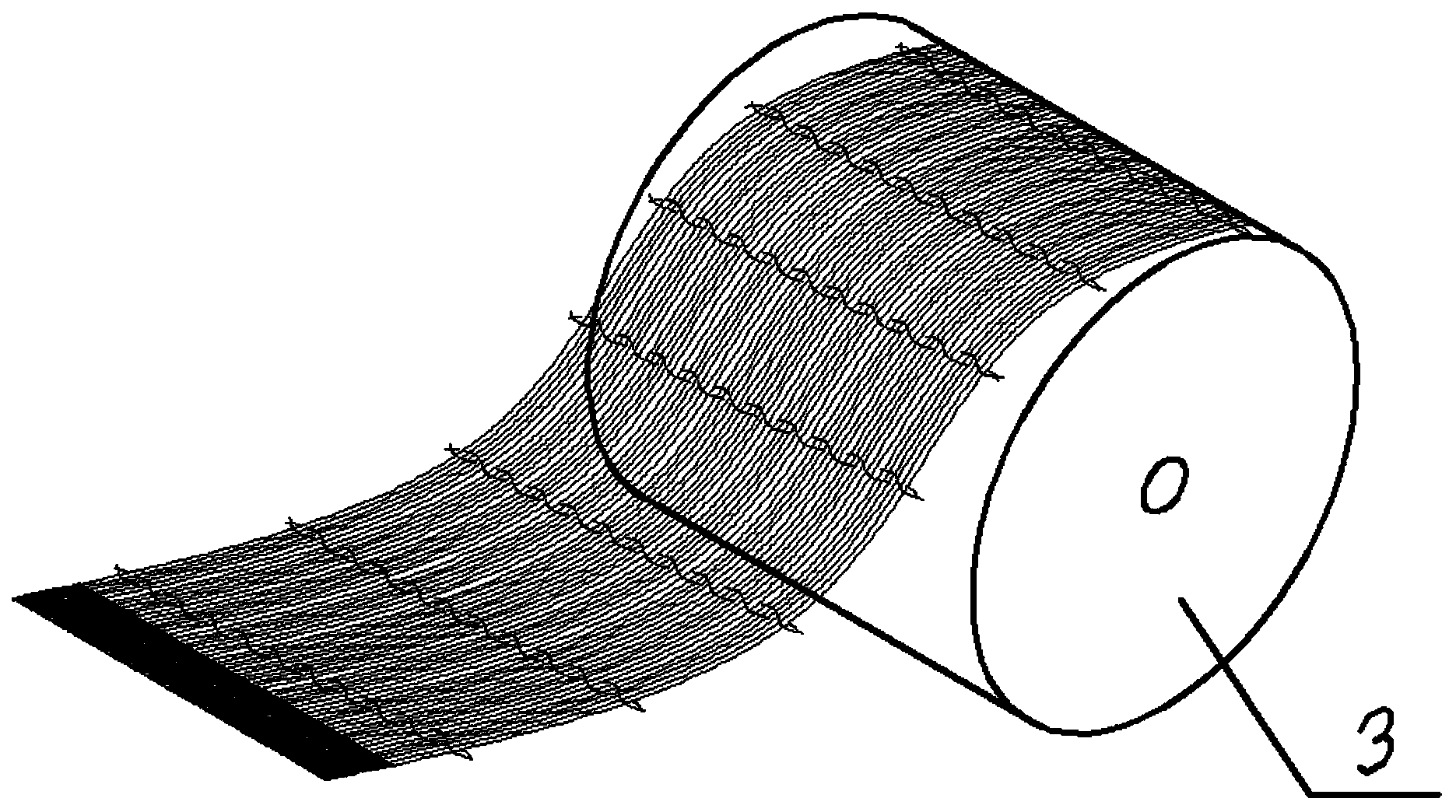

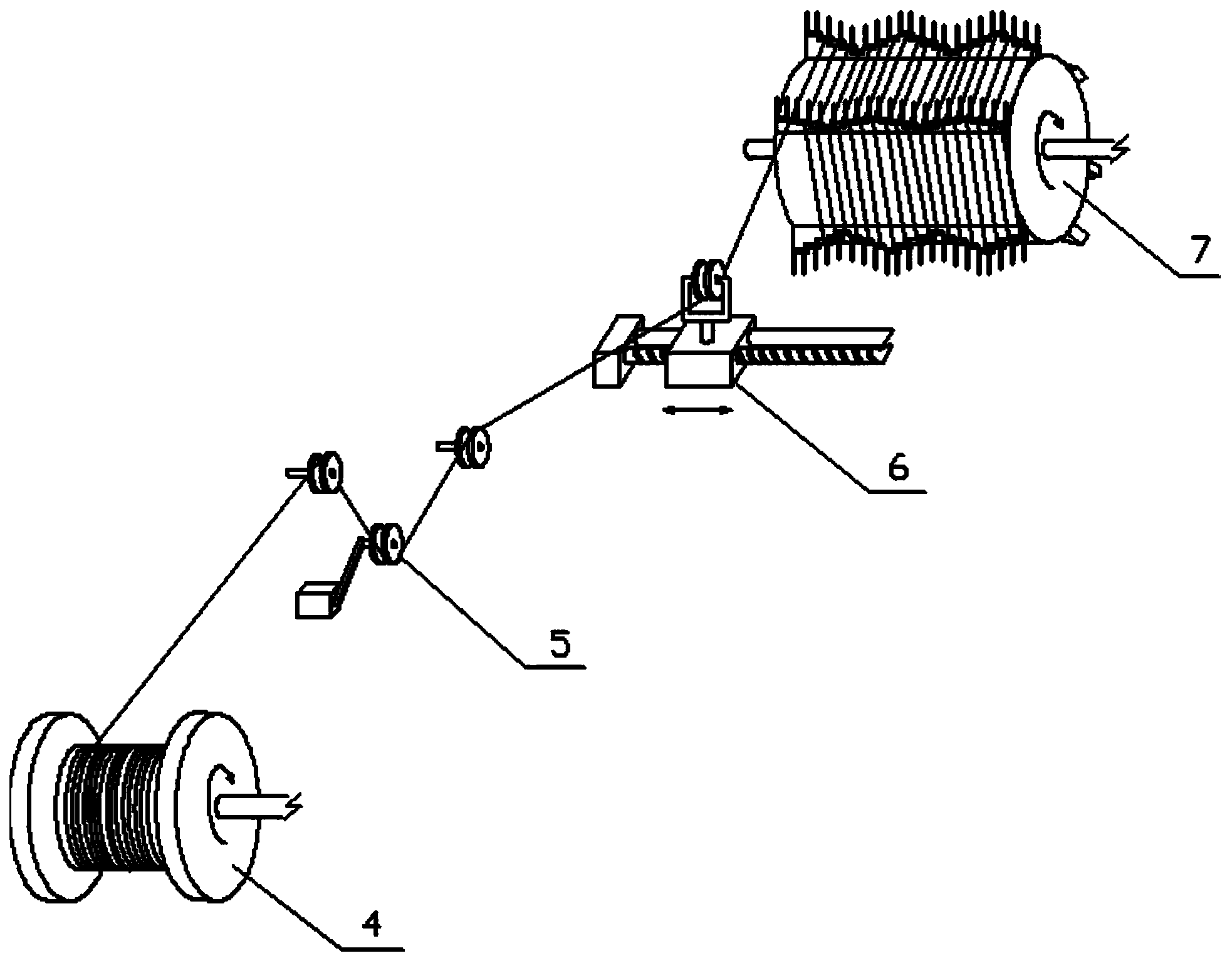

[0059] Reinforced optical fiber pad cloth for artificial light-transmitting stone, including radial optical fiber sheets, on which there are more than two latitudinal stitching glass fiber threads interspersed in the radial optical fiber sheets and stitching the radial optical fiber sheets into one ; The radial optical fiber sheet is composed of two or more glass fiber bundles arranged closely and continuously in the radial direction. There is a chemical reinforcement layer on the surface of the optical fiber monofilament. The radial optical fiber sheet is made up of 380,000 glass optical fiber monofilaments with a length of 1400mm. The distance between two adjacent weft-sewn glass fiber lines is 5cm. There are 28 glass fiber wires in total; both ends of the radial optical fiber sheet have shaped sections with a length of 20mm.

[0060] The width of the radial optical fiber sheet is 500cm, and the thickness is 1.5mm; the diameter of the weft stitching glass fiber line is 1mm. ...

Embodiment 2

[0078] It is basically the same as in Example 1, except that the diameter of the single glass fiber is 30 μm; the width of the radial fiber sheet is 30 cm, and the thickness is 1 mm; the diameter of the weft stitched glass fiber is 0.8 mm. The distance between two adjacent latitudinal suture glass fiber lines is 4cm; the width of the notch groove is 30mm, and the depth of the notch groove is 40mm; the height of each step is 0.6cm, and the width is 2cm;

[0079] The chemical reinforcement layer is prepared by mixing alcohol solution of KH-560 and oil derivative 1140, wherein the mass content of KH-560 in the alcohol solution is 0.1%, and the mass content of oil derivative 1140 is 0.1%.

Embodiment 3

[0081] It is basically the same as that of Example 1, except that the diameter of the glass fiber monofilament is 70 μm; the width of the radial optical fiber sheet is 100 cm, and the thickness is 3 mm; the diameter of the latitudinal stitching glass fiber line is 2 mm. The distance between two adjacent latitudinal suture glass fiber lines is 8cm; the width of the notch groove is 50mm, and the depth of the notch groove is 70mm; the height of each step is 2cm, and the width is 3cm;

[0082] The chemical reinforcement layer is prepared by mixing KH-560 and oil derivative 1140 in alcohol solution, wherein the mass content of KH-560 in the alcohol solution is 5%, and the mass content of oil derivative 1140 is 10%.

[0083]Using the pads (machine discontinuous manufacturing) obtained in the above-mentioned embodiments to prepare marble, the specific process is to pour a layer of marble raw material slurry in the marble casting mold, and then lay a layer of pads, and the adjacent two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com