Brittle capsules for use in tobacco products, methods of manufacture and applications thereof

A technology of brittle capsules and tobacco products, applied in the field of tobacco products, can solve the problems of short retention time of essence and uneven release of essence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A method for the manufacture of crisp capsules used in tobacco products, the method comprising the following steps:

[0072] 1) Preparation of emulsion: the oil-soluble liquid and the aqueous solution containing multivalent metal ions are emulsified under high-speed homogeneous stirring to obtain an oil-in-water emulsion with a high oil-water ratio;

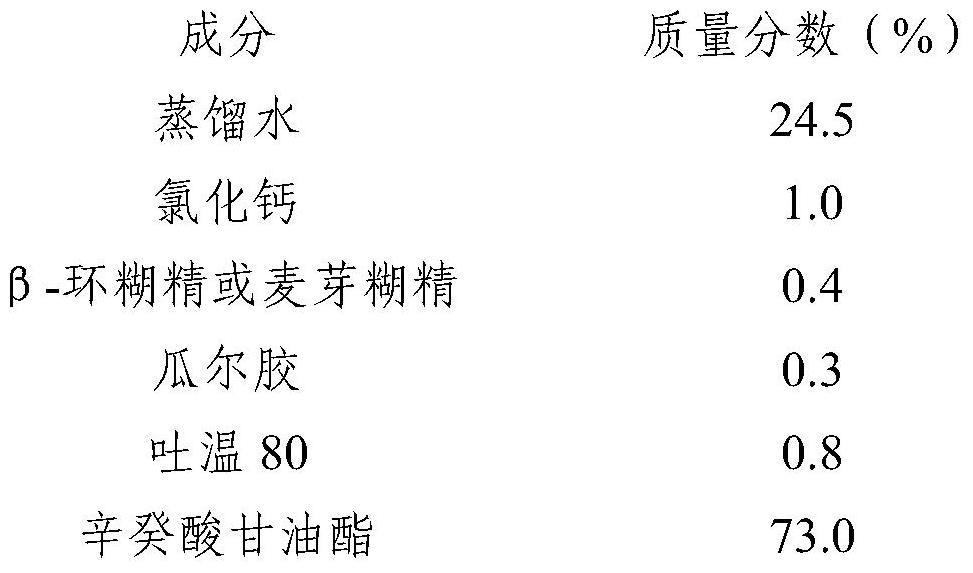

[0073] The formulation of the emulsion is as follows:

[0074]

[0075] 2) Dropping: drop the emulsion obtained in step 1) into the monovalent alginic acid salt solution (film-forming liquid) through the sharp hole forming method, and the dripping pills undergo gelation reaction in the constantly stirring film-forming liquid 30min, obtain the rudimentary capsule with certain capsule shell thickness;

[0076] The film-forming solution formula is as follows:

[0077]

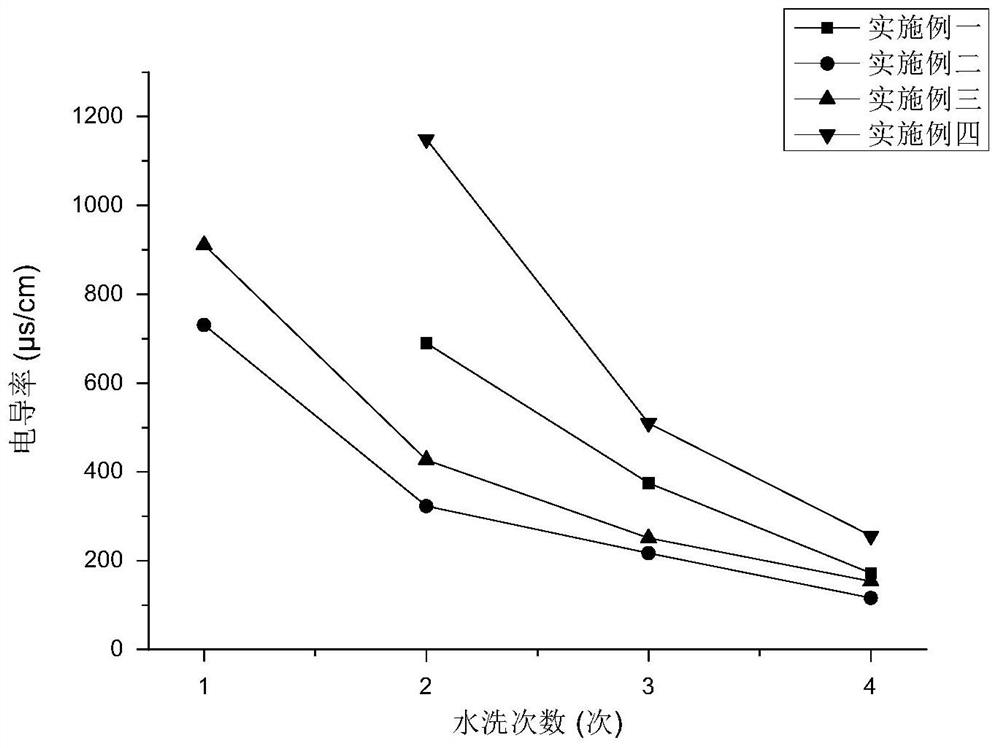

[0078] 3) Washing for the first time: wash the prototype capsule obtained in step 2) with water for the first time, and wash away excess monovalent al...

Embodiment 2

[0087] A method for manufacturing brittle capsules used in tobacco products, the difference from Example 1 is that the formula of the film-forming liquid and the second washing method are different; the formula of the film-forming liquid of this embodiment is as follows:

[0088]

[0089]

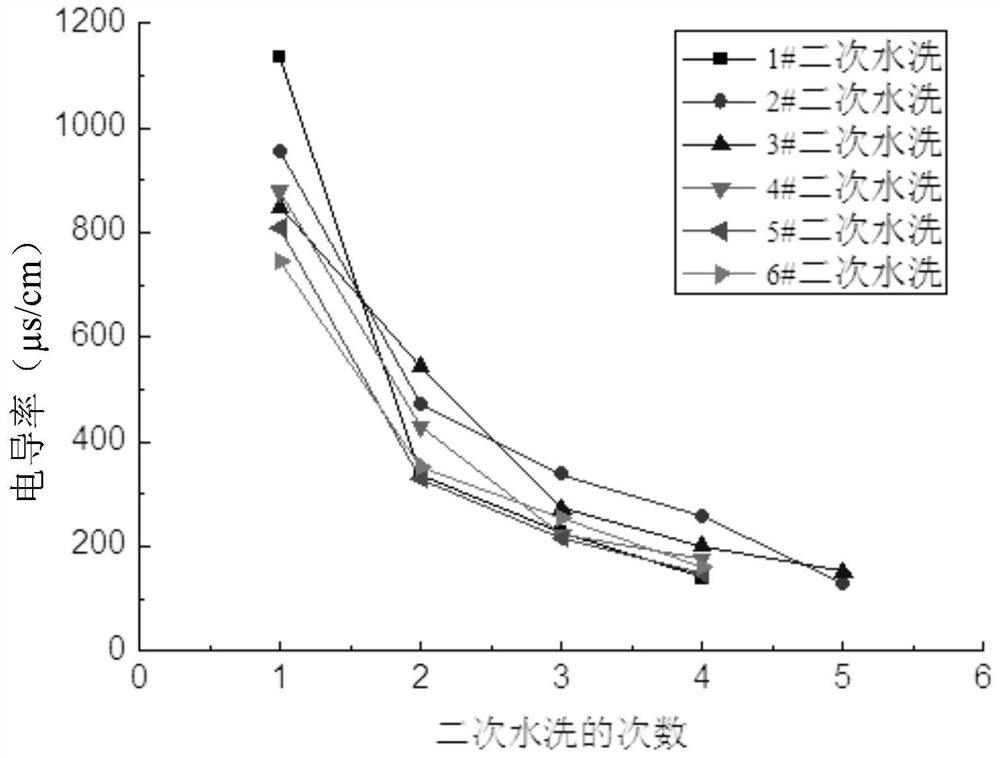

[0090] The second washing control is as follows:

[0091]

[0092] When the electrical conductivity of the final cleaning solution was 116 μs / cm in the second water washing, the drained capsules were put into a tumbler cage for preliminary setting for 2 hours. The shaped capsules are dried in the air, and the finally obtained finished capsules have good hardness and brittleness, and can withstand certain ambient temperature and humidity without dehydration with absolute ethanol and moisture-proof treatment.

Embodiment 3

[0094] A method for manufacturing brittle capsules used in tobacco products. The difference from Example 1 is that the formulation of the emulsified solution, the formulation of the film-forming solution, the curing time and the second washing method are different; the emulsified formulation of this embodiment is as follows:

[0095]

[0096] The film-forming solution formula is as follows:

[0097]

[0098] The curing time is 6 hours;

[0099] The second washing control is as follows:

[0100]

[0101]

[0102] When the electrical conductivity of the final cleaning solution was 153.8 μs / cm in the second water washing, the drained capsules were placed in a tumbler cage for preliminary shaping for 2 hours. The shaped capsules are dried in a certain environment temperature and humidity (20° C., 30%) for 18 hours to obtain target capsules with good hardness and brittleness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com