Composite panel and production method thereof

A composite board and production method technology, applied in the field of building materials, can solve the problems of continuous production difficulty, weak adhesion, waste of resources, etc., and achieve the effects of reducing glue coating process, improving adhesion stability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

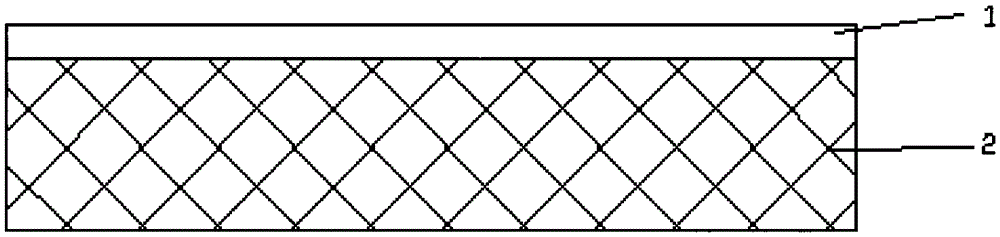

[0023] Embodiment one: if figure 1 The schematic diagram of the structure of the composite board is shown, including the surface layer 1 and the plastic composite substrate layer 2. The surface layer 1 and the plastic composite substrate layer 2 are hot-pressed and pasted together. The pasting of the surface layer 1 and the plastic composite substrate layer 2 is not used. Glue can realize that the composite board does not contain formaldehyde. After reducing the glue coating process, it is easy to realize continuous production, automatic production becomes possible, and the production efficiency is improved. At the same time, the adhesion stability between the layers of the composite board is improved. Surface layer 1 can select plastic film, ceramic tile, glass, rubber, paper, leather, metal, stone material, cloth, carpet, cork etc. for use, and surface layer 1 can also increase decal because of the needs of appearance. The plastic composite substrate 2 is extruded from a lay...

Embodiment 2

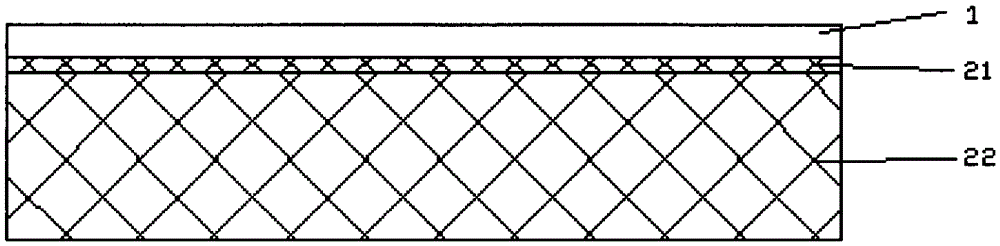

[0025] Embodiment two: if figure 2 The schematic diagram of the composite plate structure is shown, the surface layer 1 and the plastic composite substrate layer are heat-compressed and pasted together, wherein the plastic composite substrate layer is extruded and synthesized by two layers of plastic substrates 21, 22, and the two layers of plastic substrates 21, 22 All are extruded and synthesized from a mixture containing PVC powder, heavy calcium and light calcium composite powder, stabilizer, toughener, PE wax, internal lubricant, plasticizer, and impact modifier, and hot-pressed with surface layer 1 The glued plastic substrate 21 has high requirements on hardness and impact resistance. In the plastic substrate mixture formula, increase the proportion of heavy calcium and reduce the proportion of PVC powder and light calcium; plastic substrate 22 has high requirements on hardness and impact resistance. Generally, the ratio of PVC powder and light calcium is increased, the...

Embodiment 3

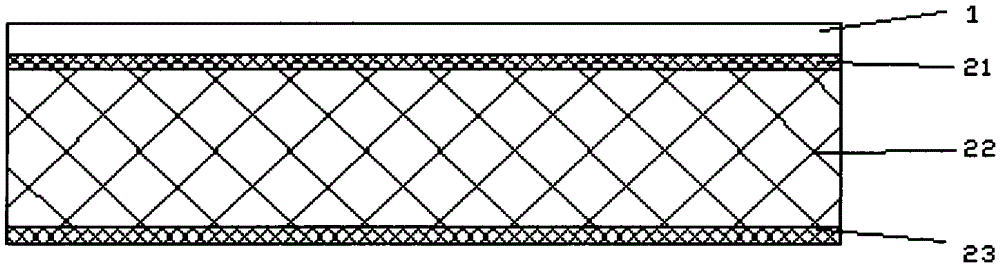

[0026] Embodiment three: as figure 2 The schematic diagram of the structure of the composite board is shown. The surface layer 1 and the plastic composite substrate layer are heat-compressed and pasted together, wherein the plastic composite substrate layer is extruded and synthesized by three layers of plastic substrates 21, 22, 23, and the three-layer plastic substrate 21 , 22, and 23 are all extruded from a mixture containing PVC powder, heavy calcium and light calcium composite powder, stabilizer, toughener, PE wax, internal lubricant, plasticizer, and impact modifier. Material 22 has low requirements on hardness and impact resistance. Generally, the proportion of PVC powder and light calcium will be increased in the formula of plastic base material mixture, the proportion of heavy calcium will be reduced, and foaming agent will be added; while plastic base material 21, 23 High requirements on hardness and impact resistance, increase the ratio of heavy calcium and reduce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com