A kind of matte polyester film for fabric cold transfer printing and its preparation method and application

A technology for cold transfer printing and polyester film, which is applied in the field of matte polyester film for cold transfer printing of fabrics and its preparation, can solve the problems of increasing production cost and operation difficulty, affecting the final quality of products, and printing white spots of downstream customers. , to reduce the coating process, improve printing white spot defects, and achieve good transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

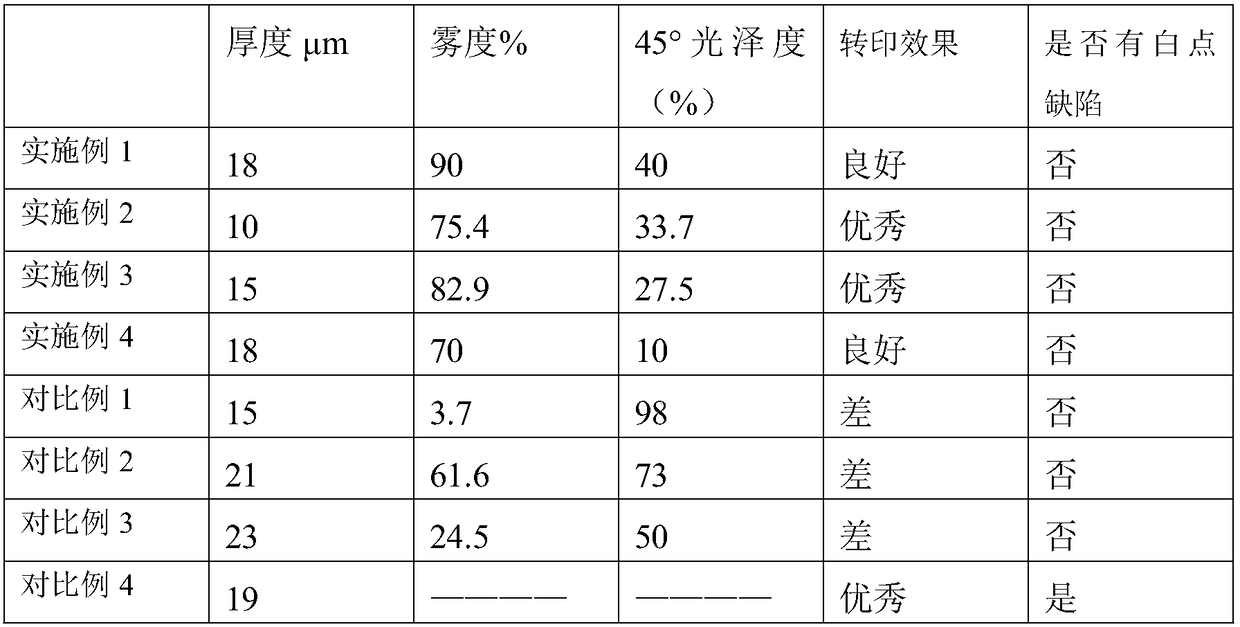

Examples

Embodiment 1

[0028] Fabric cold transfer printing matte polyester film preparation raw materials, by mass percentage:

[0029] 20% silicon-based polyester chips, 40% full-dull polyester chips, 20% regenerated particles of waste polyester materials, 20% glossy polyester chips.

[0030] Preparation of silicon-based polyester chips: use high-quality white carbon black, silicon oxide content > 99%, silicon oxide particle size range is 2μm, has excellent specific surface area and excellent dispersibility, and the mass content of silicon oxide is synthesized by DMT method 3000mg / kg silicon-based polyester chips; the intrinsic viscosity of the obtained silicon-based polyester chips is 0.645±0.01dL / g, and the moisture in the silicon-based polyester chips is <0.5% and diethylene glycol ≤1.5% according to the mass ratio.

[0031]Preparation of full-dull polyester chips: Titanium dioxide imported from Japan was selected, and full-dull polyester chips with a mass percentage of titanium dioxide of 2.0%...

Embodiment 2

[0037] Fabric cold transfer printing matte polyester film preparation raw materials, by mass percentage:

[0038] 25% silicon-based polyester chips, 15% full-dull polyester chips, 40% regenerated particles of waste polyester materials, 20% glossy polyester chips.

[0039] Preparation of silicon-based polyester chips: using high-quality white carbon black, the particle size range of silicon oxide is 10 μm, with excellent specific surface area and excellent dispersibility, using PTA method to synthesize silicon-based polyester chips with a silicon oxide mass content of 12000mg / kg Ester chips; the intrinsic viscosity of the obtained silicon-based polyester chips is 0.645±0.01dL / g, and the moisture in the silicon-based polyester chips is less than 0.5% and diethylene glycol is ≤1.5% according to the mass ratio.

[0040] Preparation of full-dull polyester chips: Titanium dioxide imported from Japan was selected, and full-dull polyester chips with a mass percentage of titanium dioxi...

Embodiment 3

[0046] Fabric cold transfer printing matte polyester film preparation raw materials, by mass percentage:

[0047] 30% silicon-based polyester chips, 10% full-dull polyester chips, 10% regenerated particles of waste polyester materials, 50% glossy polyester chips.

[0048] Preparation of silicon-based polyester chips: using high-quality white carbon black, the particle size range of silicon oxide is 5 μm, with excellent specific surface area and excellent dispersibility, and the silicon-based polyester with a silicon oxide mass content of 6000 mg / kg is synthesized by PTA method. Ester chips; the intrinsic viscosity of the obtained silicon-based polyester chips is 0.645±0.01dL / g, the moisture content in the silicon-based polyester chips is <0.5%, and the diethylene glycol is not more than 1.5%.

[0049] Preparation of full-dull polyester chips: Titanium dioxide imported from Japan was selected, and full-dull polyester chips with a mass percentage of titanium dioxide of 2.5% were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com