Barrier coating film without prime coat and preparation method thereof

A coating film and barrier coating technology, applied in the field of new polymer materials, can solve the problems of easy mechanical scratches, expensive manufacturing equipment, and difficult drying of AlOx/SiOx coatings, so as to save primer coating process, The effect of good adhesion and high oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

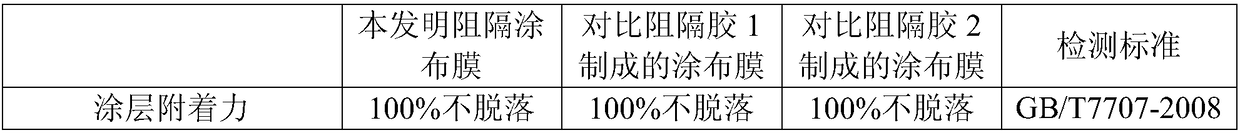

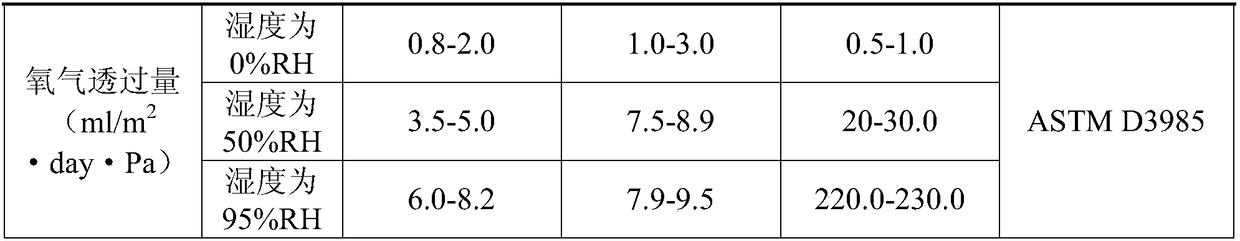

Examples

Embodiment 1

[0040] A. Preparation of PVDC emulsion:

[0041] a) Take 7kg of vinylidene chloride monomer, 1.48kg of methyl methacrylate, 0.84kg of acrylic acid, 0.3kg of methacrylonitrile, 0.02kg of sodium bicarbonate, 0.1kg of ammonium persulfate, and dodecyl diphenyl ether Sodium disulfonate 0.04kg, sodium 2-acrylamido-2-methylpropanesulfonate 0.08kg, edetate 0.04kg, deionized water 10.1kg, for use;

[0042]b) Preparation of mixed monomer and mixed emulsifier: put the prepared vinylidene chloride monomer, methyl methacrylate, acrylic acid, and methacrylonitrile in the reaction kettle, and stir evenly to make a 9.62kg mixed emulsifier. Monomer, then put the above-mentioned sodium dodecyl diphenyl ether disulfonate and 2-acrylamido-2-methyl propane sulfonate into the container, stir evenly to make 0.12kg mixed emulsifier, stand-by;

[0043] c) Initiator solution preparation: 0.09 kg of ammonium persulfate was dissolved with 1.52 kg of deionized water and set aside;

[0044] d) Preparati...

Embodiment 2

[0054] A. Preparation of PVDC emulsion:

[0055] a) Take 15.2kg of vinylidene chloride monomer, 3.2kg of methyl methacrylate, 1.54kg of methacrylic acid, 0.49kg of acrylonitrile, 0.03kg of sodium bicarbonate, 0.12kg of ammonium persulfate, dodecylbenzenesulfonate 0.06kg of sodium nitrate, 0.12kg of sodium 2-acrylamido-2-methylpropanesulfonate, 0.04kg of ethylenediaminetetraacetate, 19.2kg of deionized water, for use;

[0056] b) Preparation of mixed monomer and mixed emulsifier: put the prepared vinylidene chloride monomer, methyl methacrylate, acrylic acid, and acrylonitrile in the reaction kettle, and stir evenly to make 20.43kg of mixed monomer , the above-mentioned sodium dodecylbenzenesulfonate and 2-acrylamido-2-methylpropanesulfonate prepared above are placed in the container, stirred evenly to make 0.18kg mixed emulsifier, stand-by;

[0057] c) Initiator solution preparation: Dissolve 0.11 kg of ammonium persulfate with 3.46 kg of deionized water and set aside;

[00...

Embodiment 3

[0068] A. Preparation of PVDC emulsion:

[0069] a) Take 24kg of vinylidene chloride monomer, 4.08kg of methyl methacrylate, 2.1kg of acrylic acid, 0.6kg of methacrylonitrile, 0.04kg of sodium bicarbonate, 0.02kg of ammonium persulfate, and 2 sec-dodecylsulfonic acid 0.06kg of sodium, 0.12kg of sodium 2-acrylamido-2-methylpropanesulfonate, 0.12kg of ethylenediaminetetraacetate, 28.86kg of deionized water, for use;

[0070] b) Preparation of mixed monomer and mixed emulsifier: put the above prepared vinylidene chloride monomer, methyl methacrylate, acrylic acid, and methacrylonitrile in a reaction kettle, and stir evenly to make a 30.78kg mixed emulsifier. Monomer, then place the above-mentioned sodium dodecyl sulfonate and 2-acrylamido-2-methylpropanesulfonate prepared in the container, stir to make 0.18kg mixed emulsifier, stand-by;

[0071] c) Initiator solution preparation: Dissolve 0.11 kg of ammonium persulfate with 3.46 kg of deionized water and set aside;

[0072] d) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com