A kind of water-based steel drum paint, preparation process and use

A preparation process and technology for steel drums, applied in epoxy resin coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problems of long drying time, short storage period, long time consumption, etc. Grinding and retort resistance, improving the efficiency of the reaction, increasing the effect of curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

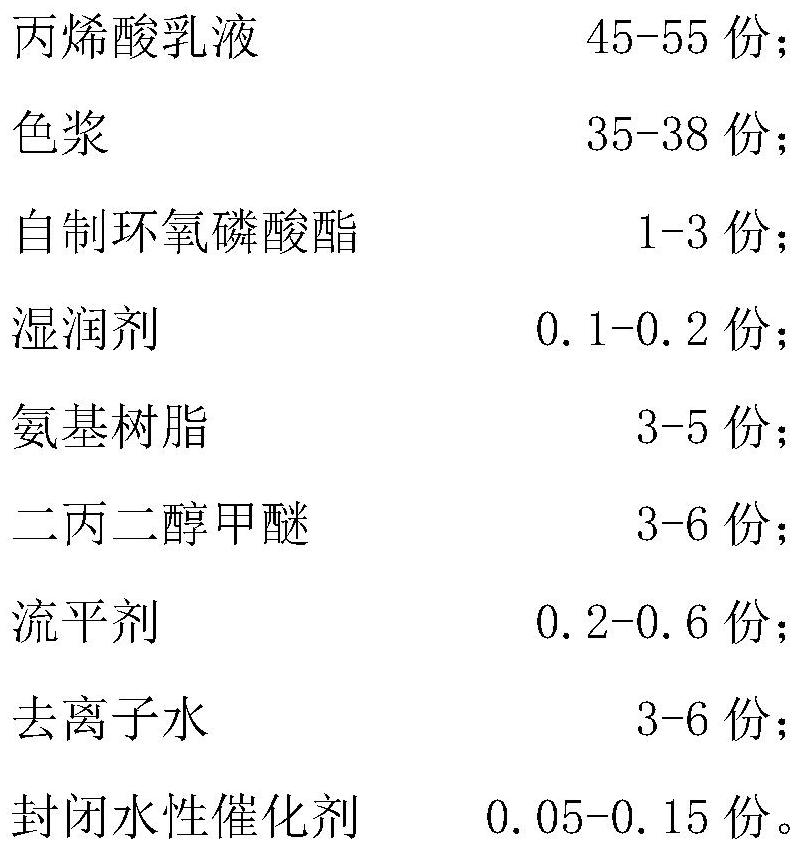

[0059] The invention discloses a preparation process of water-based steel drum paint, comprising the following steps:

[0060] S1: prepare epoxy modified acrylic resin;

[0061] Specifically, the preparation process of the self-made epoxy-modified acrylic resin described in step S1 is as follows:

[0062] S11: Prepare primer: prepare 15-20 parts of ethylene glycol butyl ether, dissolve 35-45 parts of Nantong Xingchen 901 solid epoxy resin into an epoxy solution, add 18-30 parts of acrylic monomer, and use it as primer after mixing spare;

[0063] S12: Preparation of monomer mixed solution: 17-30 parts of styrene, 45-65 parts of butyl acrylate, 5-15 parts of methyl methacrylate, 1-5 parts of hydroxypropyl acrylate, 3-5 parts of peroxide 2 - tert-butyl ethylhexanoate (TBPO) initiator and 10-20 parts of propylene glycol methyl ether solvent are mixed to make a mixed solution;

[0064] S13: Prepare other materials: additionally prepare 0.2-1.0 parts of tert-butyl peroxide 2-eth...

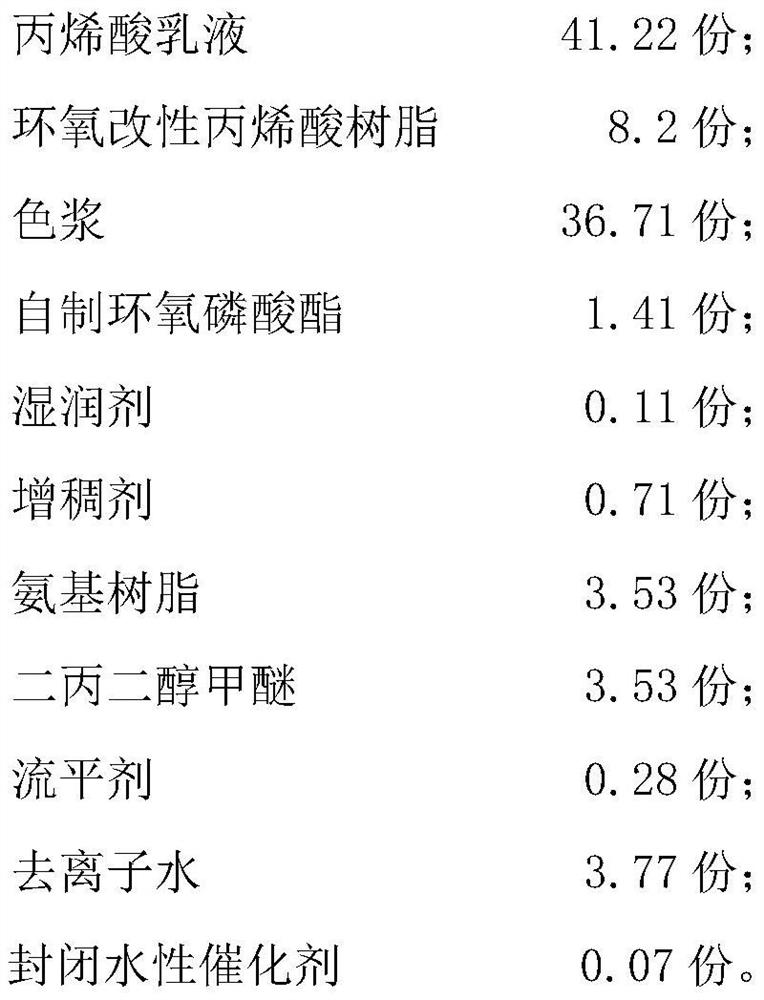

Embodiment 1

[0072] Including the following processes:

[0073] S11: Prepare primer: prepare 18 parts of butyl glycol ether, dissolve 42 parts of Nantong Xingchen 901 solid epoxy resin into an epoxy solution, add 25 parts of acrylic monomer, and use it as a primer after mixing;

[0074] S12: Preparation of monomer mixed solution: 24 parts of styrene, 55 parts of butyl acrylate, 10 parts of methyl methacrylate, 3 parts of hydroxypropyl acrylate, 4.2 parts of tert-butyl peroxide 2-ethylhexanoate initiator And 12 parts of propylene glycol methyl ether solvent are mixed to make a mixed solution;

[0075] S13: Prepare other materials: prepare 0.4 parts of tert-butyl peroxide 2-ethylhexanoate initiator, 0.8 parts of propylene glycol methyl ether solution as supplementary initiator, 10 parts of n-butanol, 32.4 parts of ethylene glycol butyl ether as diluent , 2.6 parts of dimethylethanolamine are used as neutralizing agent;

[0076] S14: Stir and mix:

[0077] S141: heating the primer prepared...

Embodiment 2

[0102] S21: Prepare an epoxy solution: heat 4.6 parts of butyl glycol ether and 8.6 parts of Nantong Xingchen 850S epoxy resin to 45°C under stirring, and dissolve it to prepare an epoxy solution;

[0103] S22: Pre-dissolving: dissolve 0.87 parts of 85% phosphoric acid, 0.4 parts of deionized water and 0.8 parts of ethylene glycol butyl ether at room temperature in advance;

[0104] S23: Prepare other materials: prepare 3.7 parts of ethylene glycol butyl ether and 1 part of dimethylethanolamine;

[0105] S24: Phosphating:

[0106] S241: adding the epoxy solution prepared in step S22 to the pre-dissolved material in step S21, heating to 60°C for 1 hour, then heating to 100°C-110°C within 1 hour, and keeping the temperature for 3 hours;

[0107] S242: add 3.3 parts of ethylene glycol butyl ether and cool to 50°C;

[0108] S243: Add 1 part of dimethylethanolamine and 0.4 part of ethylene glycol butyl ether, and stir evenly to prepare a water-soluble epoxy phosphate resin L1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com