Alloy anode material for aluminum-air battery, preparation method thereof and aluminum-air battery

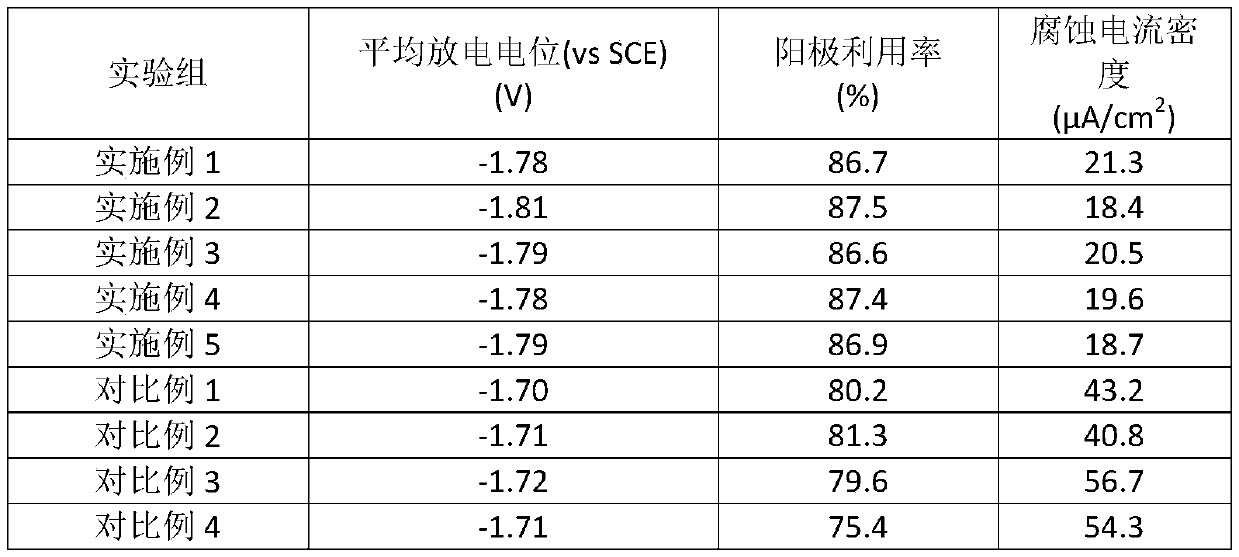

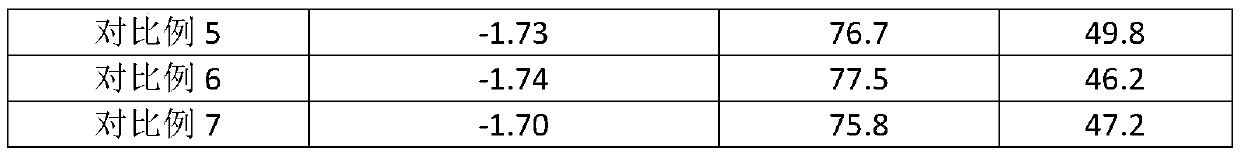

An aluminum-air battery and alloy anode technology, applied in the field of electrochemistry, can solve problems such as low discharge potential, and achieve the effect of low discharge potential and high anode utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The method for preparing an alloy anode material for an aluminum-air battery provided in an embodiment of the present invention includes: preparing the alloy anode material for an aluminum-air battery from a raw material containing Pb, Bi, Ga, Li, B and Al, wherein Pb in the raw material is , Bi, Ga, Li, B and Al are configured according to the chemical composition of alloy anode materials for aluminum-air batteries.

[0041] Specifically include:

[0042] S1. First melt 99.99% pure aluminum ingot in the melting furnace and heat it up to 700-800°C, keep it warm for 10-40 minutes, and then add alloying elements to the molten aluminum, among which the alloying elements Pb, Bi, Ga, and B are pure metals respectively. The alloy element Li is added in the form of Al-Li master alloy. After adding alloying elements, the alloy melt is heated to 720-820°C and held for 30-60 minutes. After refining and standing, it is poured to make a billet. The pouring temperature is 710-810°C...

Embodiment 1

[0050] The alloy anode material for an air battery provided in this embodiment has the following chemical composition by mass fraction: 1.4% Pb, 1.8% Bi, 0.8% Ga, 0.6% Li, 0.0008% B, and the rest is Al.

[0051] Its preparation method is as follows:

[0052] In the smelting furnace, 99.99% pure aluminum ingots are first melted and heated to 750°C, kept for 30 minutes, and then pure Pb, pure Bi, pure Ga, pure B and Al-Li intermediate alloys are successively added according to the composition requirements. After adding alloying elements, the alloy melt is heated to 760°C and held for 40 minutes. After refining and standing still, it is poured to make a billet. The pouring temperature is 740°C.

[0053] Perform homogenization annealing on the slab, the homogenization annealing temperature is 450°C, and the holding time is 18h; after removing the oxide layer on the surface of the ingot, the slab is rolled to 1.5mm, and then heat treated, the annealing temperature is 380°C, and the a...

Embodiment 2

[0055] The alloy anode material for an air battery provided in this embodiment has the following chemical composition by mass fraction: 0.01% Pb, 2.5% Bi, 0.01% Ga, 2% Li, 0.0001% B, and the rest is Al.

[0056] Its preparation method is as follows:

[0057] In the smelting furnace, 99.99% pure aluminum ingots are first melted and heated to 700°C, kept for 40 minutes, and then pure Pb, pure Bi, pure Ga, pure B and Al-Li intermediate alloys are successively added according to the composition requirements. After adding alloying elements, the alloy melt is heated to 720°C and held for 60 minutes. After refining and standing still, it is poured to make a slab, and the pouring temperature is 710°C.

[0058] Homogenizing annealing is carried out on the slab, the homogenizing annealing temperature is 420°C, and the holding time is 24h; after removing the oxide layer on the surface of the ingot, the slab is rolled to 1.5mm, and then heat treated, the annealing temperature is 350°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com