Application of red phosphorus/carbon nanotube composite material in sodium ion capacitor

A technology of carbon nanotubes and composite materials, which is applied in the application field of red phosphorus/carbon nanotube composite materials in sodium ion capacitors, and can solve problems such as electrode damage and slow diffusion of sodium ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

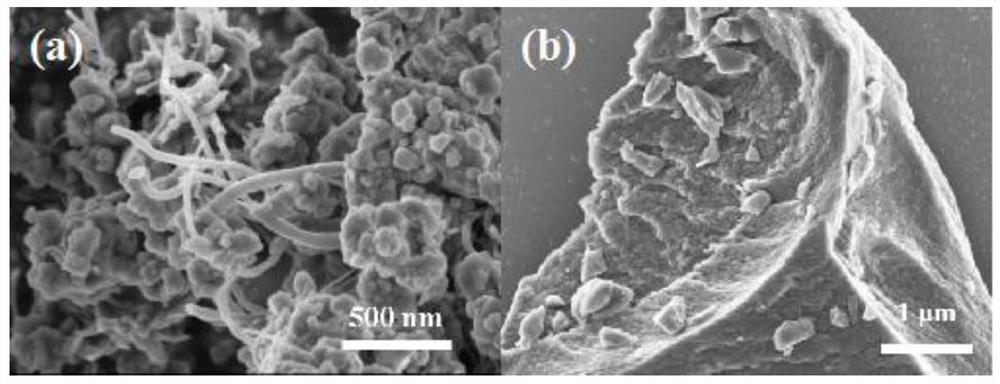

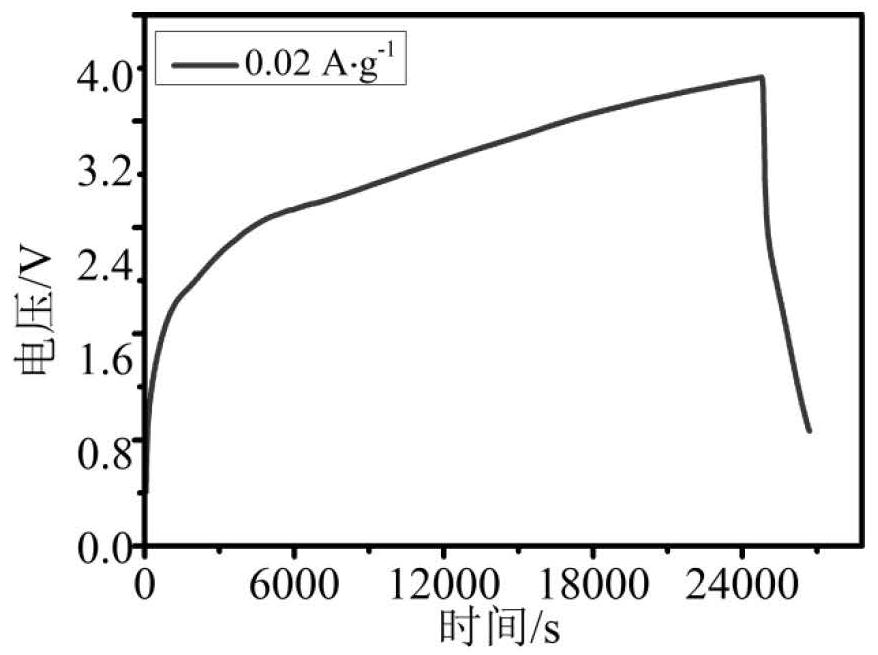

Embodiment 1

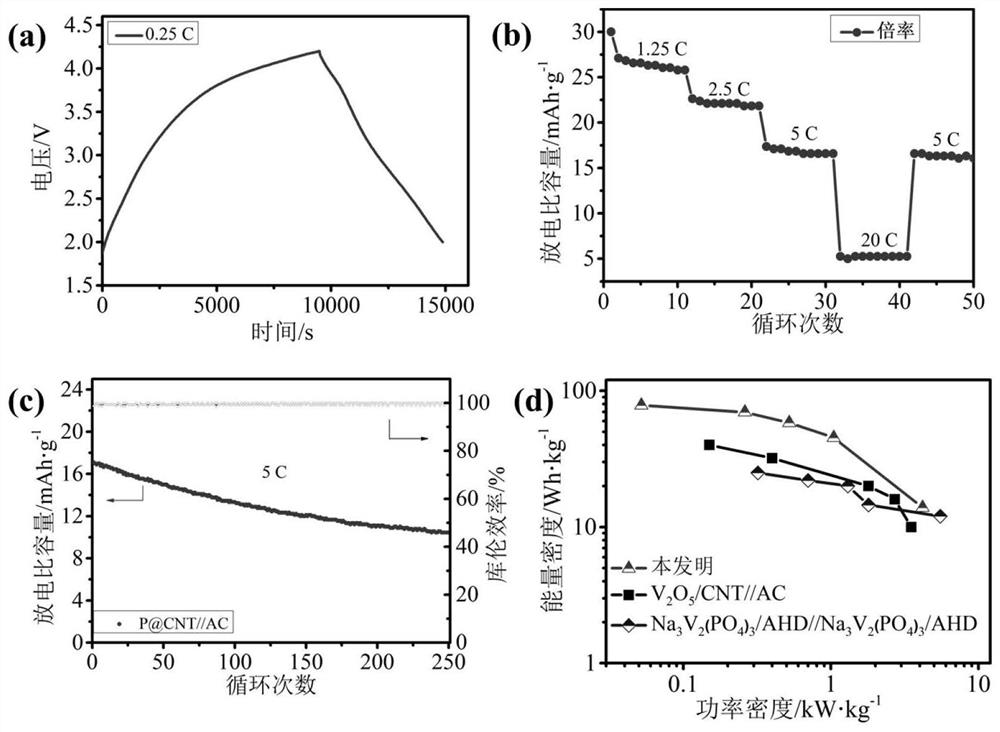

[0038] Under an argon protective atmosphere, the red phosphorus was put into a ball mill jar for ball milling for 24 hours at a milling speed of 500 r / min. The obtained red phosphorus and carbon nanotubes are uniformly mixed according to the mass ratio of 2:1, and the obtained mixture is put into a glass tube to evacuate into a vacuum atmosphere, and heated with a muffle furnace. The temperature program of the muffle furnace is set as follows: at 5°C min -1 Raise the temperature to 450°C at a rate of 2 hours, then keep it at this temperature for 2 hours, and then increase the temperature at 2°C·min -1 Cooled to 300°C at a constant rate, then maintained at this temperature for 12 hours, and finally cooled naturally to room temperature. Finally, the red phosphorus / carbon nanotube composite material is obtained. The obtained red phosphorus / carbon nanotube composite material is used as the negative electrode, and the activated carbon is used as the positive electrode to assemble...

Embodiment 2

[0042]Under an argon protective atmosphere, the red phosphorus was put into a ball mill jar for ball milling for 24 hours at a milling speed of 500 r / min. The obtained red phosphorus and carbon nanotubes are uniformly mixed according to the mass ratio of 2:1, and the obtained mixture is put into a glass tube to evacuate into a vacuum atmosphere, and heated with a muffle furnace. The temperature program of the muffle furnace is set as follows: at 5°C min -1 Raise the temperature to 450°C at a rate of 2 hours, then keep it at this temperature for 2 hours, and then increase the temperature at 2°C·min -1 Cooled to 300°C at a constant rate, then maintained at this temperature for 12 hours, and finally cooled naturally to room temperature. Finally, the red phosphorus / carbon nanotube composite material is obtained. The obtained red phosphorus / carbon nanotube composite material is used as the negative electrode, and the activated carbon is used as the positive electrode to assemble ...

Embodiment 3

[0045] Under an argon protective atmosphere, the red phosphorus was put into a ball mill jar for ball milling for 20 hours, and the ball milling speed was 600r / min. The obtained red phosphorus and carbon nanotubes are uniformly mixed according to the mass ratio of 2:1, and the obtained mixture is put into a glass tube to evacuate into a vacuum atmosphere, and heated with a muffle furnace. The temperature program of the muffle furnace is set as follows: at 3°C min -1 Raise the temperature to 450°C at a rate of 2 hours, then keep it at this temperature for 2 hours, and then increase the temperature at 2°C·min -1 Cooled to 300°C at a constant rate, then maintained at this temperature for 12 hours, and finally cooled naturally to room temperature. Finally, the red phosphorus / carbon nanotube composite material is obtained. The obtained red phosphorus / carbon nanotube composite material is used as the negative electrode, and the activated carbon is used as the positive electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com