Integrated device for pearl producing, screening and cleaning

A pearl and cleaning technology, applied in sieves, solid separation, chemical instruments and methods, etc., can solve the problems of high work intensity, difficult work efficiency, time-consuming and laborious, and achieve the effect of improving stability and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

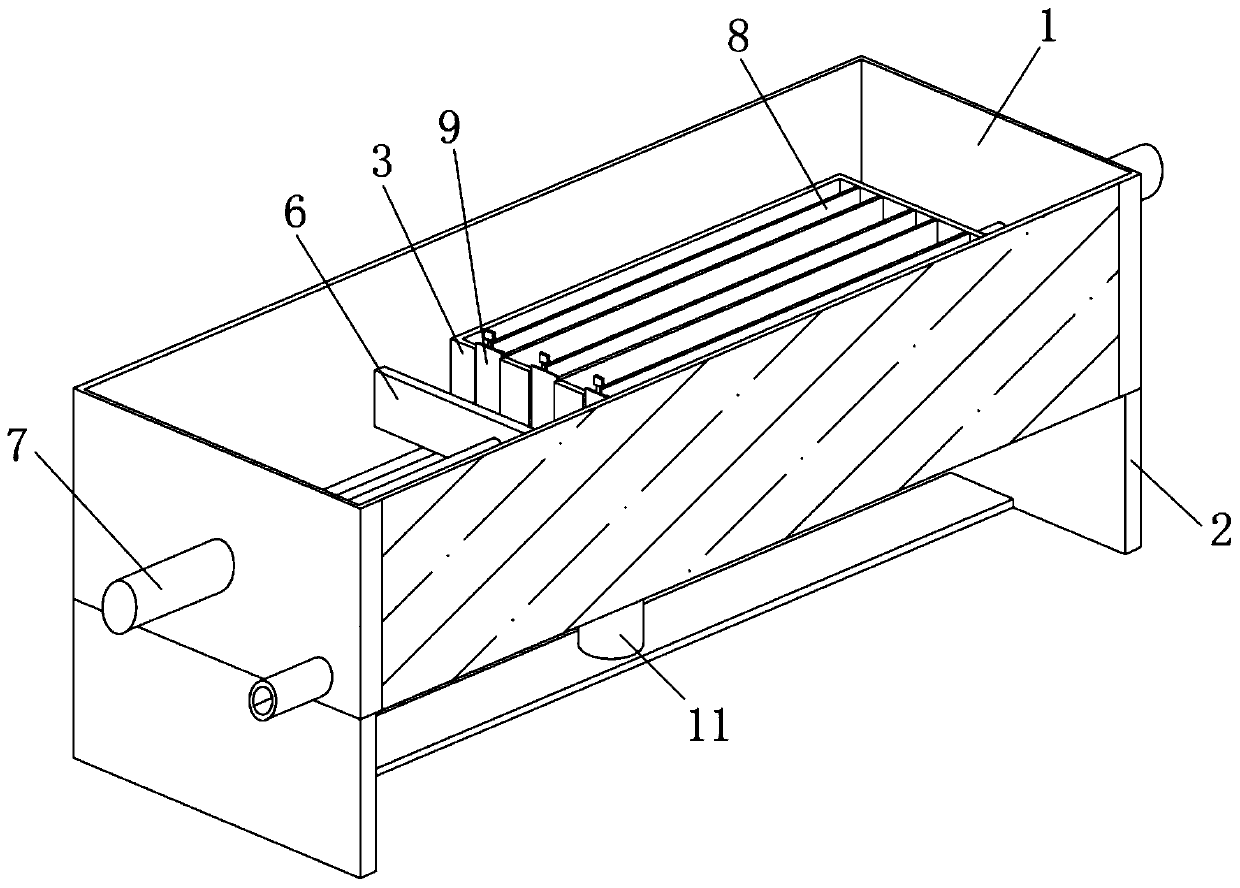

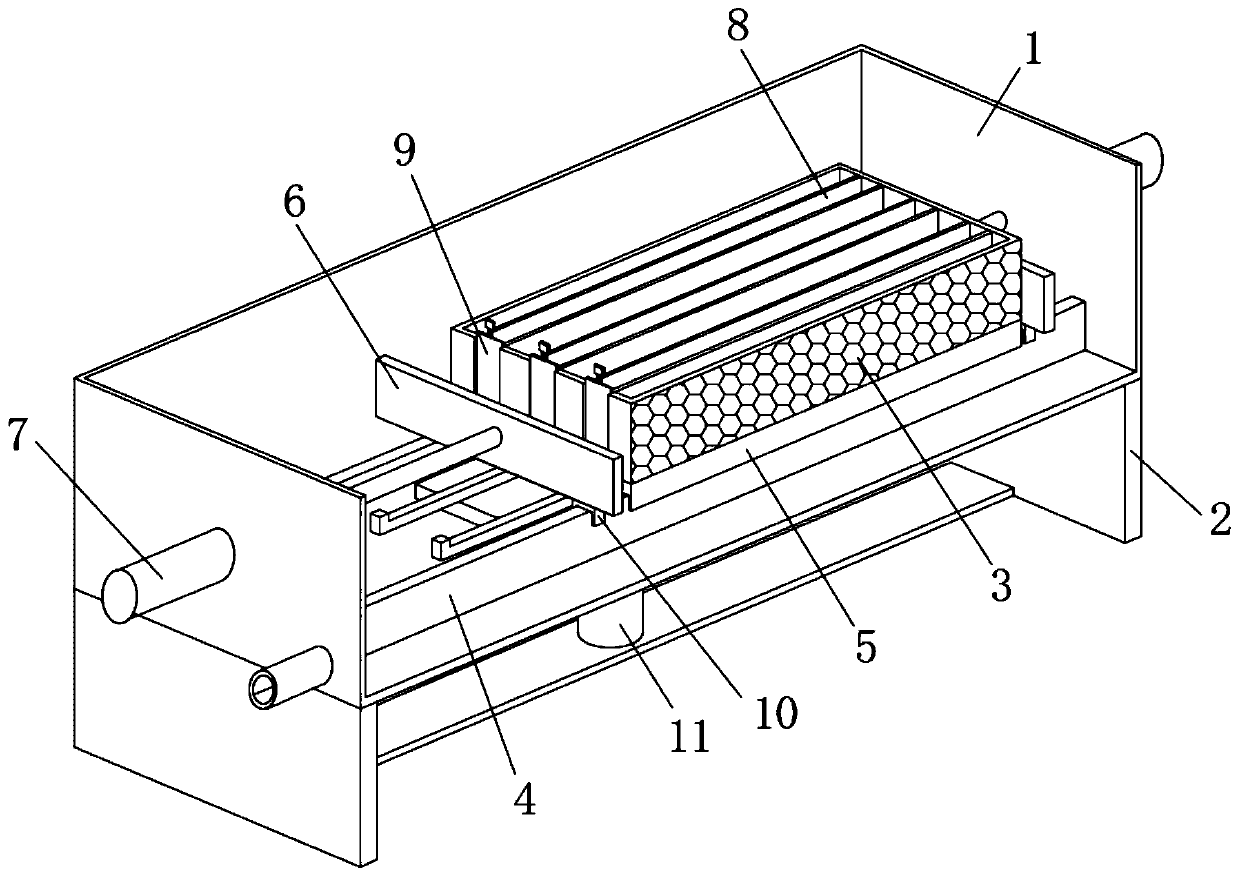

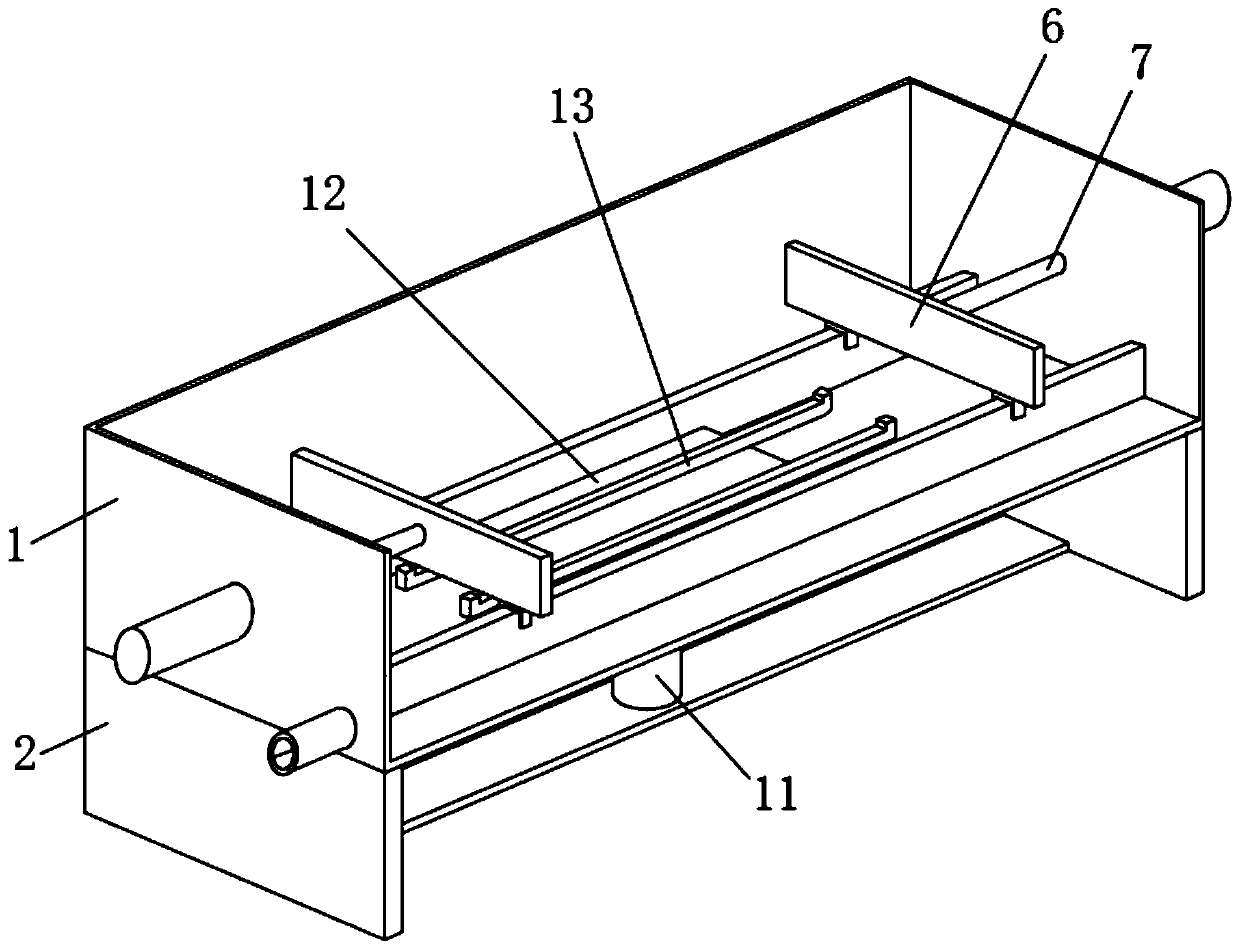

[0040] see figure 1 , an integrated device for pearl production, screening and cleaning, comprising a cleaning box 1 and a screening box 3 slidingly connected to the inner bottom of the cleaning box 1, both sides of the lower end of the cleaning box 1 are fixedly connected with support seats 2, and there are placed in the cleaning box Cleaning fluid, the bottom of the cleaning box 1 is provided with a drain pipe with a valve, the pearls to be cleaned and screened are placed in the screening box 3, the inner bottom of the cleaning box 1 is fixedly connected with a strip slide 4 on both sides, and the screening box The two sides of the bottom end of 3 are slidably connected to two strip slide plates 4 respectively. Match the sliding cavity of the sliding connection, and the strip-shaped sliding plate 4 and the sliding cavity are rectangular structures, and the hollow sliding frame 5 is slidably connected to the strip-shaped sliding plate 4. Those skilled in the art pass the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com