Steel plate substrate skiing jumping platform slideway snowmaking base layer treatment structure and method

A base-level treatment and substrate technology, applied in the field of infrastructure construction of snow sports projects, can solve the problems of low friction between steel plates and snow, difficult to adhere to the thermal conductivity of snow-melting water drainage steel plates, etc. Solve the effect of snowmelt water drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

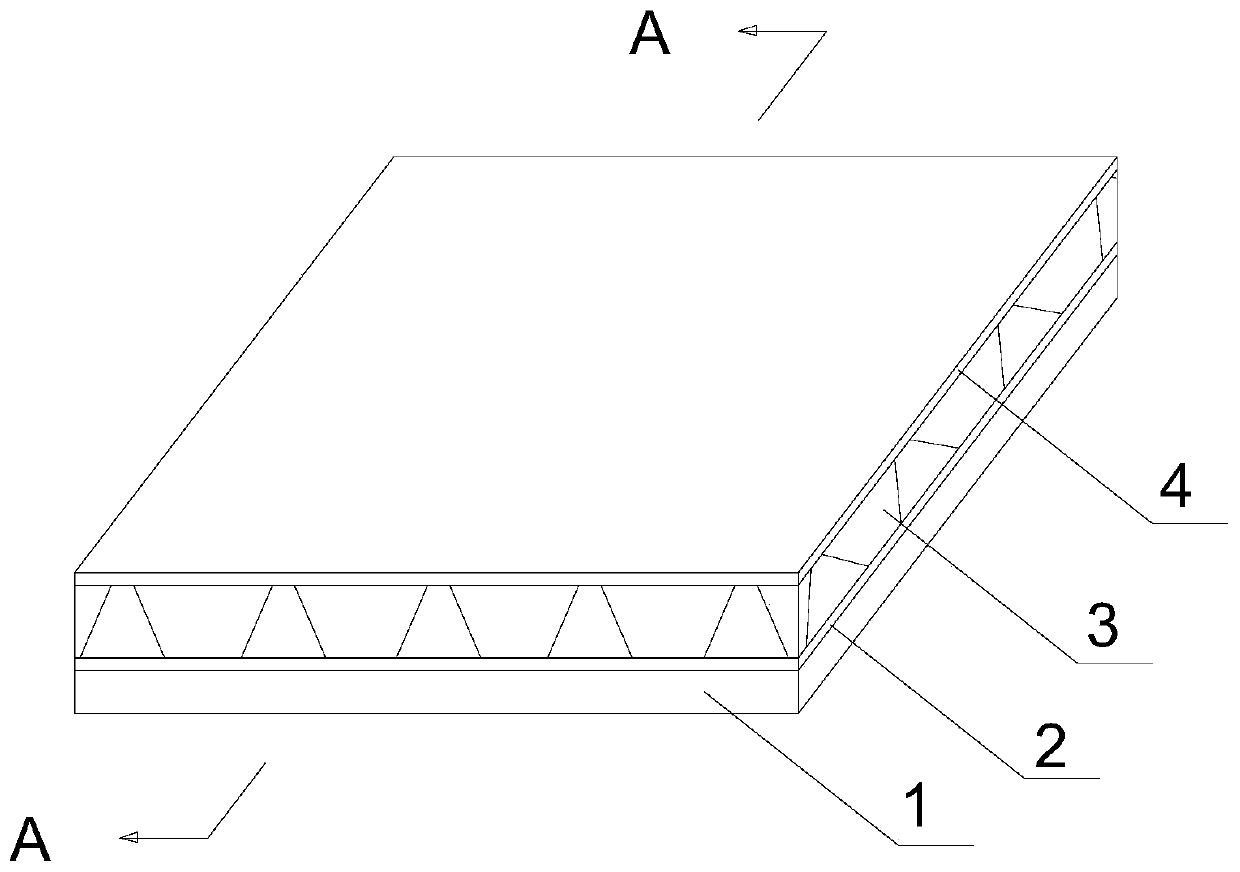

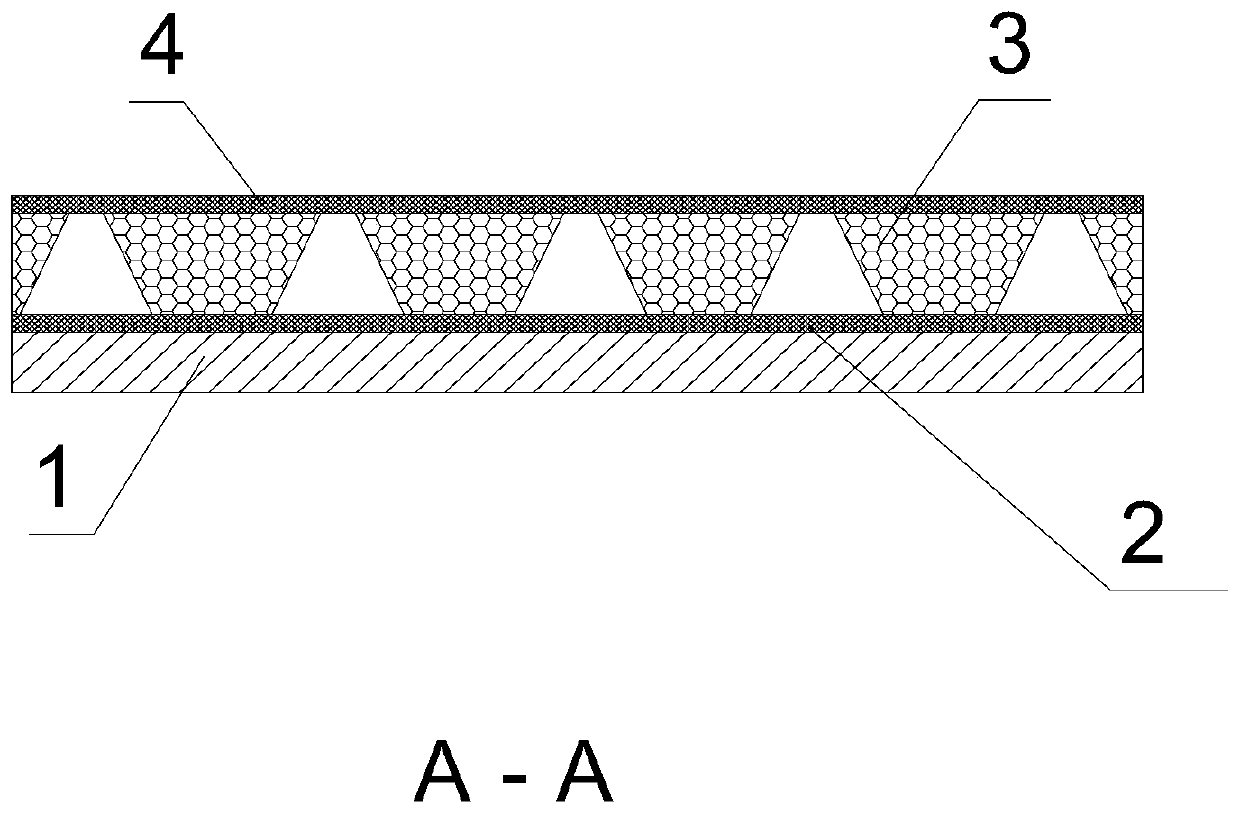

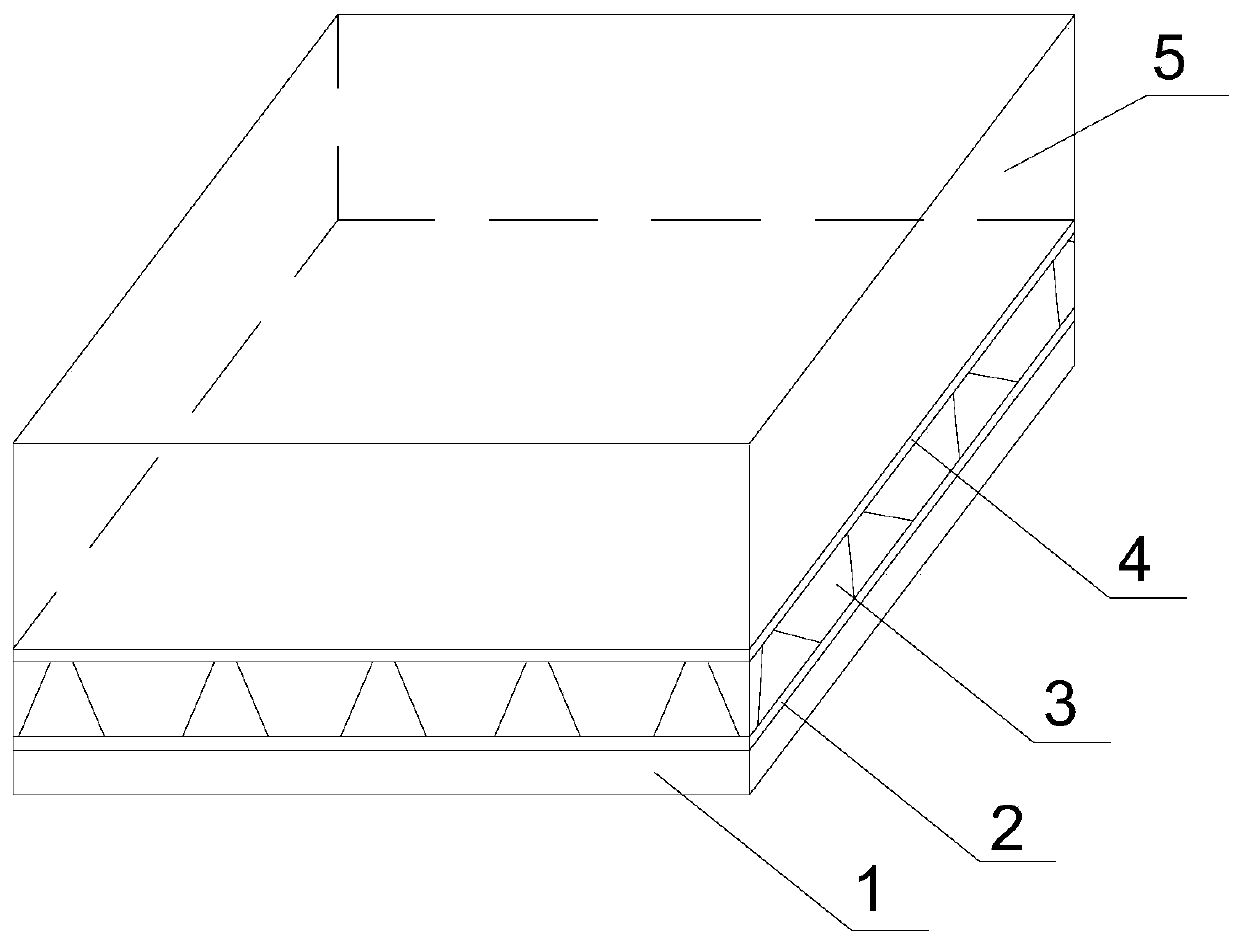

[0016] The invention comprises a steel plate base 1, a non-woven protective layer 2, a concave-convex hydrophobic plate 3, a non-woven filter protective surface layer 4, and a snowmaking layer 5.

[0017] 1. Apply adhesive glue on the entire surface of the steel plate base 1 to completely bond the non-woven fabric protective layer 2 on the steel plate base 1 .

[0018] 2. Then, apply glue on the entire surface of the non-woven protective layer 2 to completely bond the concave-convex hydrophobic plate 3 on the non-woven protective layer 2 .

[0019] 3. Finally, apply glue on the entire surface of the concave-convex hydrophobic plate 3 to completely bond the non-woven filter protection surface layer 4 on the concave-convex hydrophobic plate 3, and attach the snow-making layer 5 to the non-woven filter protective surface layer 4 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com