Novel phosphoric acid process active carbon production converter

A technology of activated carbon production and converter, applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unsuitable control of the temperature in the carbonization section of the furnace tail, insufficient impregnation degree of sawdust and phosphoric acid, and weakened catalytic effect of phosphoric acid, etc., to achieve Reduce the content of phosphoric acid, increase the yield, and reduce the effect of burning ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

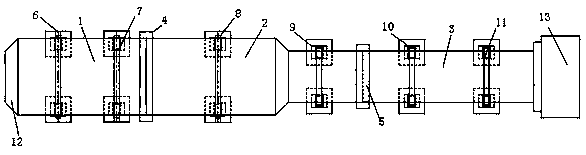

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

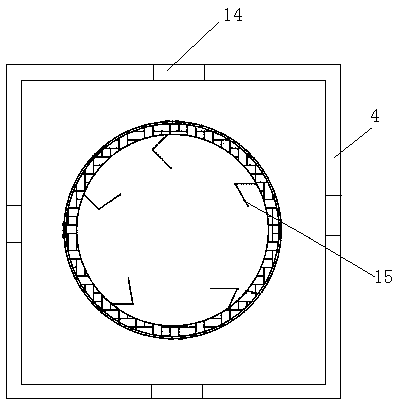

[0013] like figure 1 , figure 2 As shown, a new type of converter for the production of phosphoric acid activated carbon includes a preheating section converter 1, a carbonization section converter 2 and an activation section converter 3, and the preheating section converter 1, carbonization section converter 2 and activation section converter 3 are sequentially connected along the axial direction ;

[0014] The discharge end of the preheating section converter 1 and the feed end of the carbonization section converter 2 are provided with a connecting part A4. The connecting part A4 has a shell structure. The feed end of the furnace is sealed in the shell, and there is a gap between the discharge end of the converter 1 in the preheating section and the feed end of the converter 2 in the carbonization section to facilitate the entry of hot gas, and a heat supply vent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com