Device and method for running casing operation by using turnbuckle faucet

A faucet and casing technology, which is applied to drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of untimely circulation of mud and rotating casing when casing is run, so as to improve production efficiency and safety, The effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

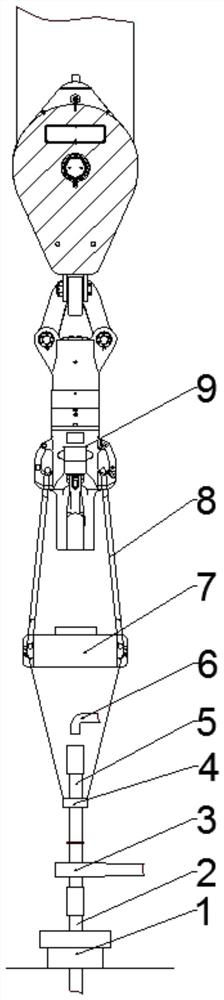

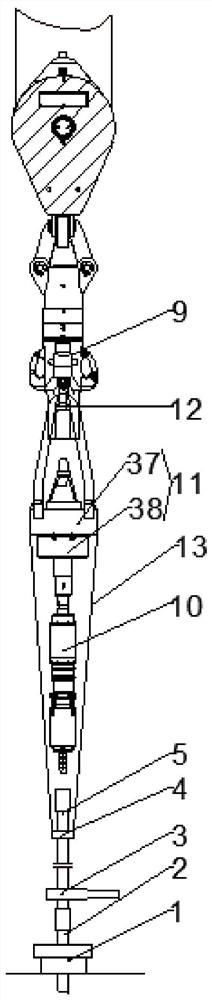

[0057] The device for running the casing by using the turnbuckle faucet, including: the main winch, the big hook 9 driven by the main winch to move up and down, the main hook body 12, the drill floor slips 1 on the drill floor, hydraulic casing tongs 3. It also includes: a turnbuckle faucet 11 suspended on the main hook body 12 of the big hook 9, a sleeve clamping head 10 detachably fixed to the bottom end of the turnbuckle faucet 11, and a wire rope 13 suspended on the bottom of the turnbuckle faucet. The casing elevator 4 on the turnbuckle faucet 11 and below the turnbuckle faucet 11 and the casing clamping head 10, wherein the turnbuckle faucet 11 includes a common faucet 37 and is detachable from the common faucet 37 The provided spinner 38, the common faucet 37 can specifically be an XSL225 type faucet, and the spinner 38 is a 225 spinner;

[0058] The operation method of the device using the turnbuckle faucet for casing operation includes the following steps:

[0059] S...

Embodiment 2

[0070] The device for running the casing by using the turnbuckle faucet, including: the main winch, the big hook 9 driven by the main winch to move up and down, the main hook body 12, the drill floor slip 1 arranged on the drill floor, and also includes: suspension The turnbuckle faucet 11 on the main hook body 12 of the big hook 9, the casing clamping head 10 detachably connected to the bottom end of the turnbuckle faucet 11, is suspended on the turnbuckle faucet 11 through a wire rope 13 And the casing elevator 4 and hydraulic casing tongs 3 located below the turnbuckle faucet 11 and the casing clamping head 10;

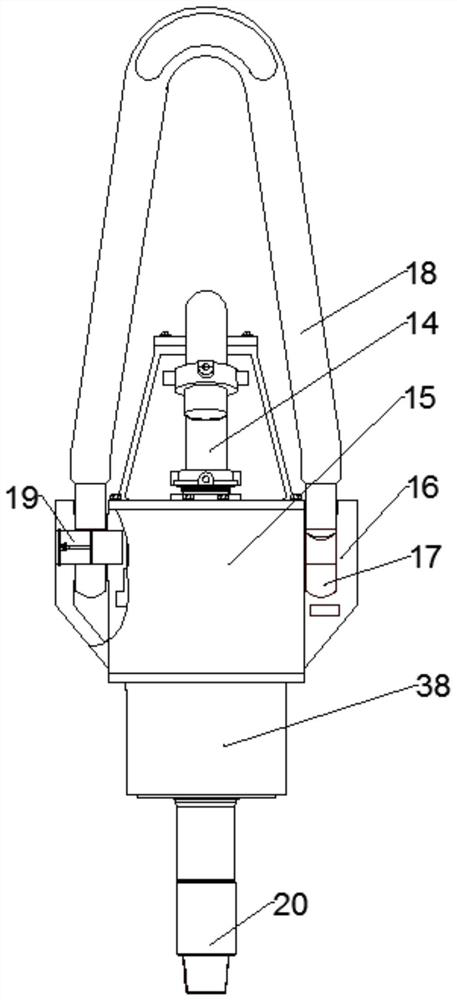

[0071] Wherein, the turnbuckle faucet 11 includes an ordinary faucet 37 and a turnbuckle 38 detachably arranged with the ordinary faucet 37, the gooseneck of the turnbuckle faucet 11 is connected with the water hose of the mud circulation system, and the ordinary faucet 37 includes a basic The function is similar to the faucet body 14 of the XSL225 type faucet, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com