Endogenous microbial single-well throughput oil recovery method

A technology for endogenous microorganisms and oil wells, which is applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc. It can solve the problems that affect the single-well huff and puff of endogenous microorganisms, and cannot effectively activate endogenous microorganisms. Cost-saving, targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

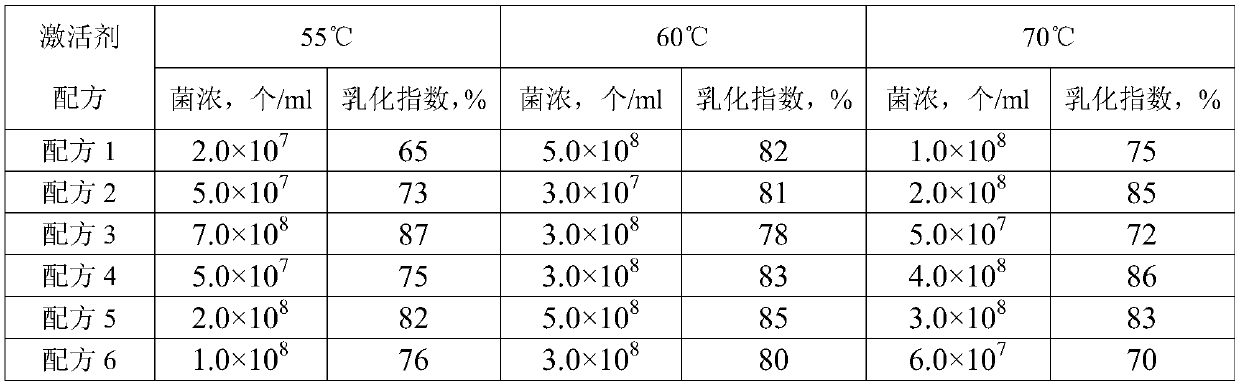

Embodiment 1

[0031] Test well F 2 Overview: Reservoir temperature is 62°C, formation water salinity is 8562mg / L, permeability is 750×10 -3 μm 2 , crude oil viscosity 2536mPa.s, water content 95.5%, test oil well has 3 oil layers, respectively F 2 1 , F 2 2 , F 2 3 , the temperature of the oil layer is 55°C, 60°C, and 70°C respectively, the total thickness of the oil layer is 8.2m, and the daily oil production of the oil well before the test is 1.2t. Implement the concrete steps of the present invention in this well as follows:

[0032] (1) Screening of test wells

[0033] Test well F 2 The reservoir temperature is 62°C, the formation water salinity is 8562mg / L, and the permeability is 750×10 -3 μm 2 , Crude oil viscosity 2536mPa.s, water content 95.5%, oil layer layer position is 3 layers, meets the screening standard of the present invention, can implement the present invention.

[0034] (2) Screening of activators

[0035] The specific steps of the screening of activators ar...

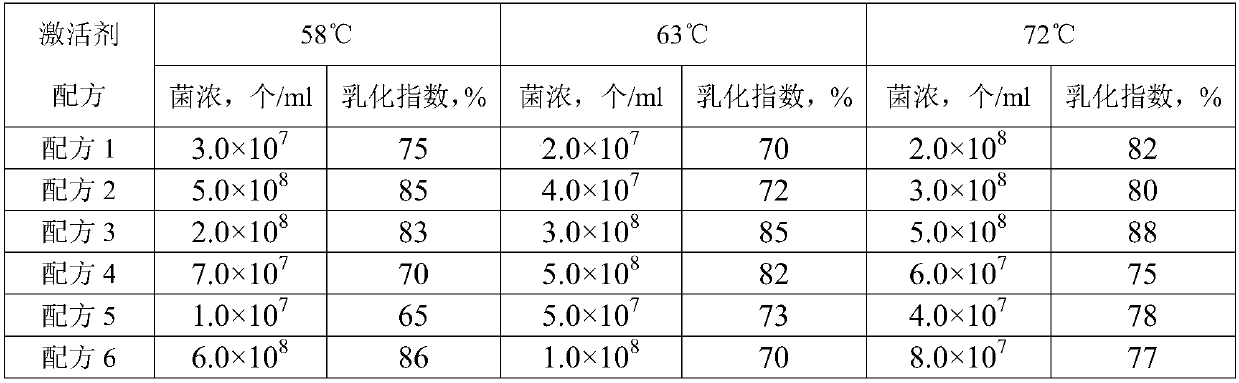

Embodiment 2

[0053]Test well F 5 Overview: Reservoir temperature is 65°C, formation water salinity is 12536mg / L, permeability is 900×10 -3 μm 2 , crude oil viscosity 3250mPa.s, water content 95.0%, test oil well has 3 oil layers, respectively F 5 1 , F 5 2 , F 5 3 , the temperature of the oil layer is 58°C, 63°C, and 72°C respectively, the total thickness of the oil layer is 12.5m, and the daily oil production of the oil well before the test is 2.1t. Implement the present invention in this well, concrete steps are as follows:

[0054] (1) Screening of test wells

[0055] Test well F 5 The reservoir temperature is 65°C, the formation water salinity is 12536mg / L, and the permeability is 900×10 -3 μm 2 , Crude oil viscosity 3250mPa.s, water content 95.0%, oil layer layer is 3 layers, meets the screening standard of the present invention, can implement the present invention.

[0056] (2) Screening of activators

[0057] The specific steps of the screening of activators are as foll...

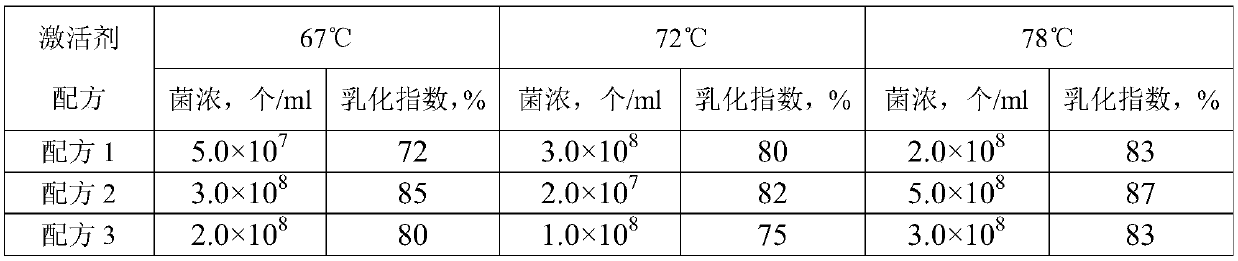

Embodiment 3

[0075] Test well F 12 Overview: Reservoir temperature is 70°C, formation water salinity is 4562mg / L, permeability is 1100×10 -3 μm 2 , crude oil viscosity 1856mPa.s, water content 94.8%, the test oil well has 3 oil layers, respectively F 12 1 , F 12 2 , F 12 3 , the oil layer temperature is 67°C, 72°C, 78°C respectively, the total thickness of the oil layer is 10.0m, and the daily oil production of the oil well before the test is 1.8t. Implement the concrete steps of the present invention in this well as follows:

[0076] (1) Screening of test wells

[0077] Test well F 12 The reservoir temperature is 70°C, the formation water salinity is 4562mg / L, and the permeability is 1100×10 -3 μm 2 , Crude oil viscosity 1856mPa.s, water content 94.8%, oil layer layer position is 3 layers, meets the screening standard of the present invention, can implement the present invention.

[0078] (2) Screening of activators

[0079] The specific steps of the screening of activators a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water salinity | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com