Hybrid module with separating clutch outside of the housing

A technology of hybrid power module and separation clutch, which is applied in the direction of hybrid electric vehicles, fluid-driven clutches, clutches, etc., can solve the problems of separation bearing extra structural space, control force limitation, etc., and achieve axial structural space saving, simple ventilation, and energy saving The effect of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

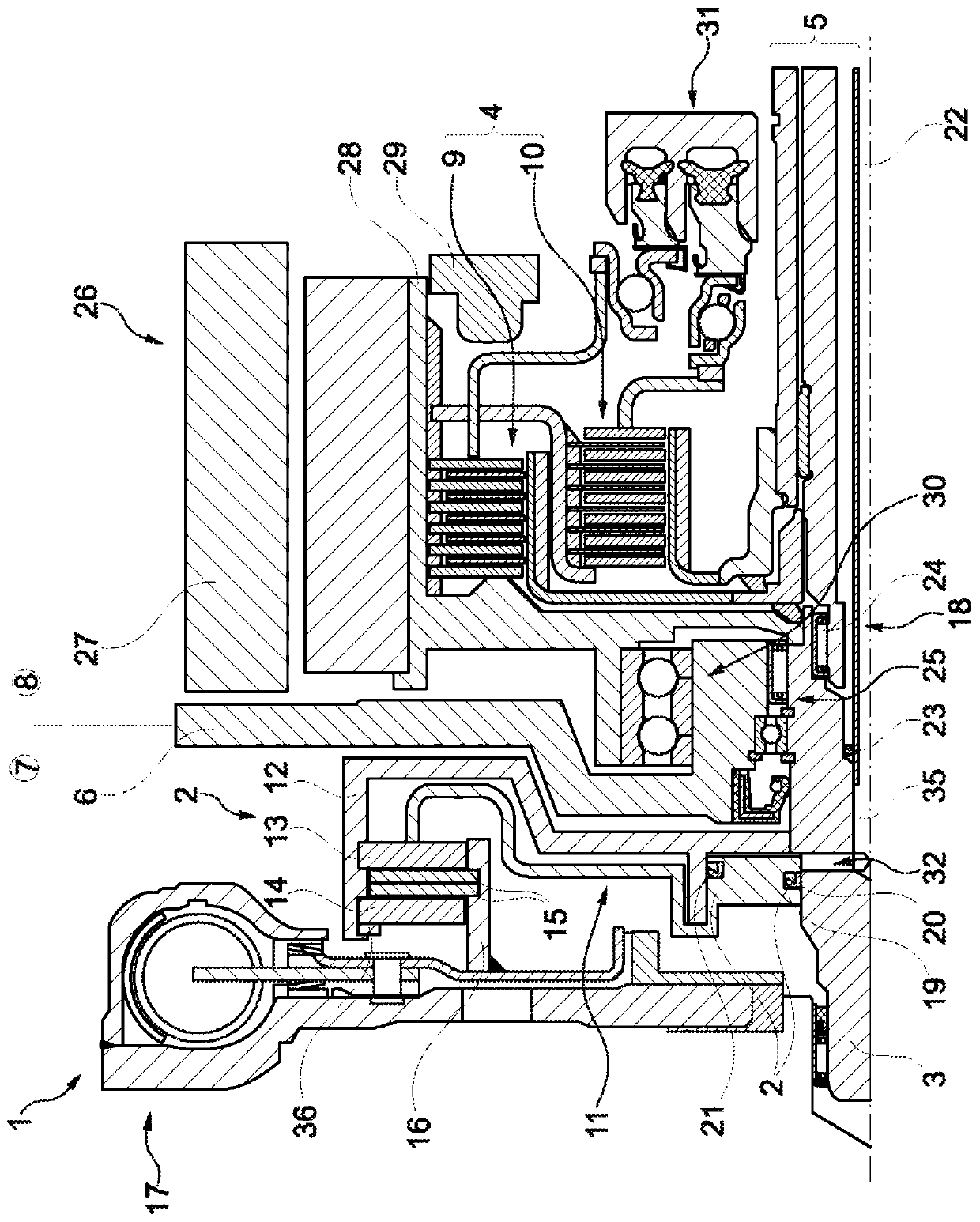

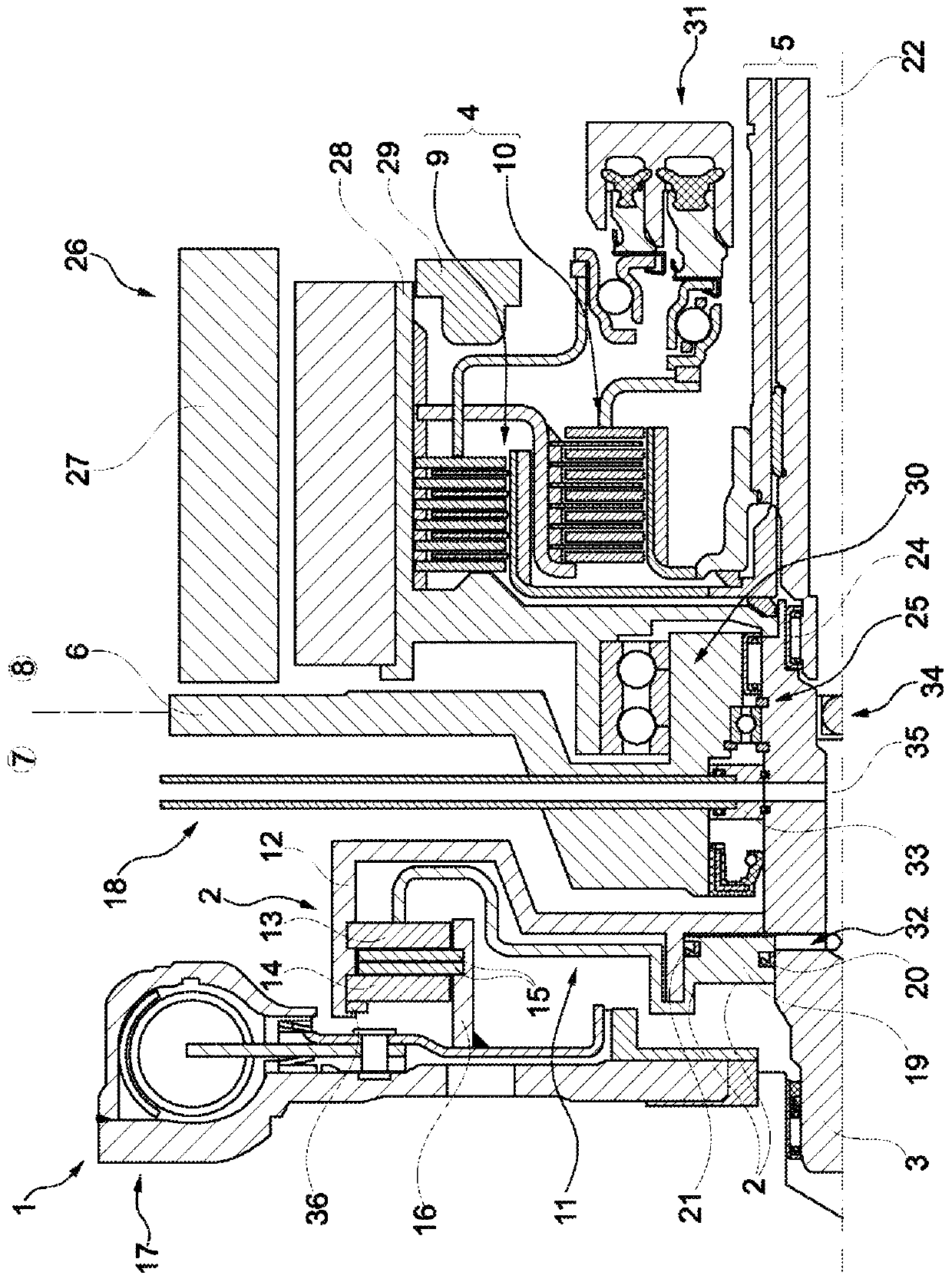

[0021] The drawings are merely exemplary and are used only for understanding the invention. The same elements are provided with the same reference numerals.

[0022] Features of various embodiments can be implemented in other embodiments as well. Therefore they can replace each other.

[0023] figure 1 An exemplary embodiment of a hybrid module 1 is shown, which is used, for example, in a drive train of a motor vehicle. The hybrid module 1 has a separating clutch (also referred to as K0 clutch) 2 for selectively coupling and disengaging an internal combustion engine (not shown) with an electric motor-drivable intermediate shaft 3 and a clutch device 4 , The clutch arrangement is equipped for the selective transmission of torque to the transmission input shaft 5 .

[0024] Furthermore, the hybrid module 1 has a housing 6 , which spatially separates the separating clutch 2 and the clutch device 4 from one another and thus divides the installation space into a dry area 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com