Method for improving performance of gas turbine

A technology of gas turbine and performance, which is applied in the directions of gas turbine device, combustion method, engine function, etc., can solve the problems of high disassembly and combination, undesired, cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the same reference numerals denote the same or similar components.

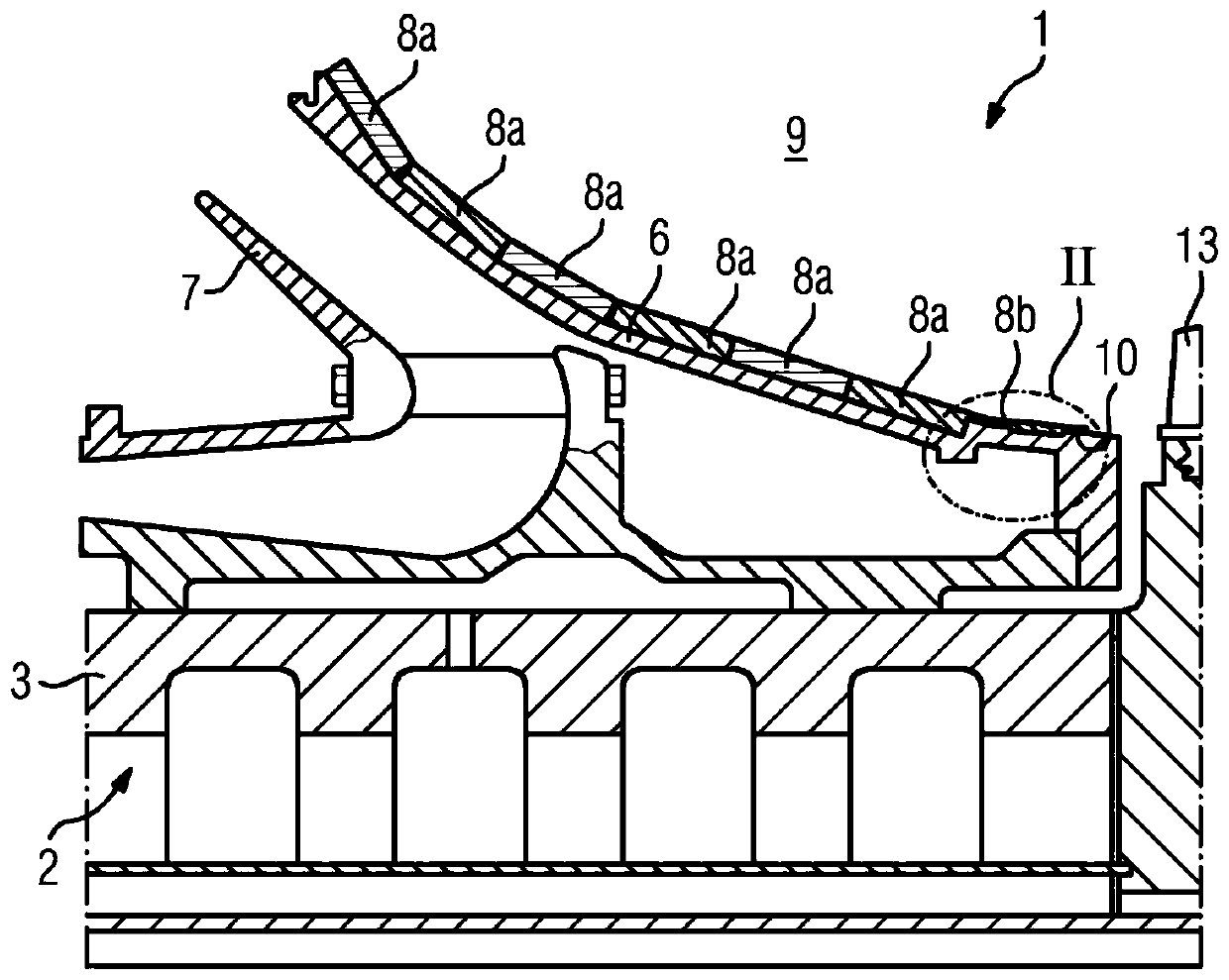

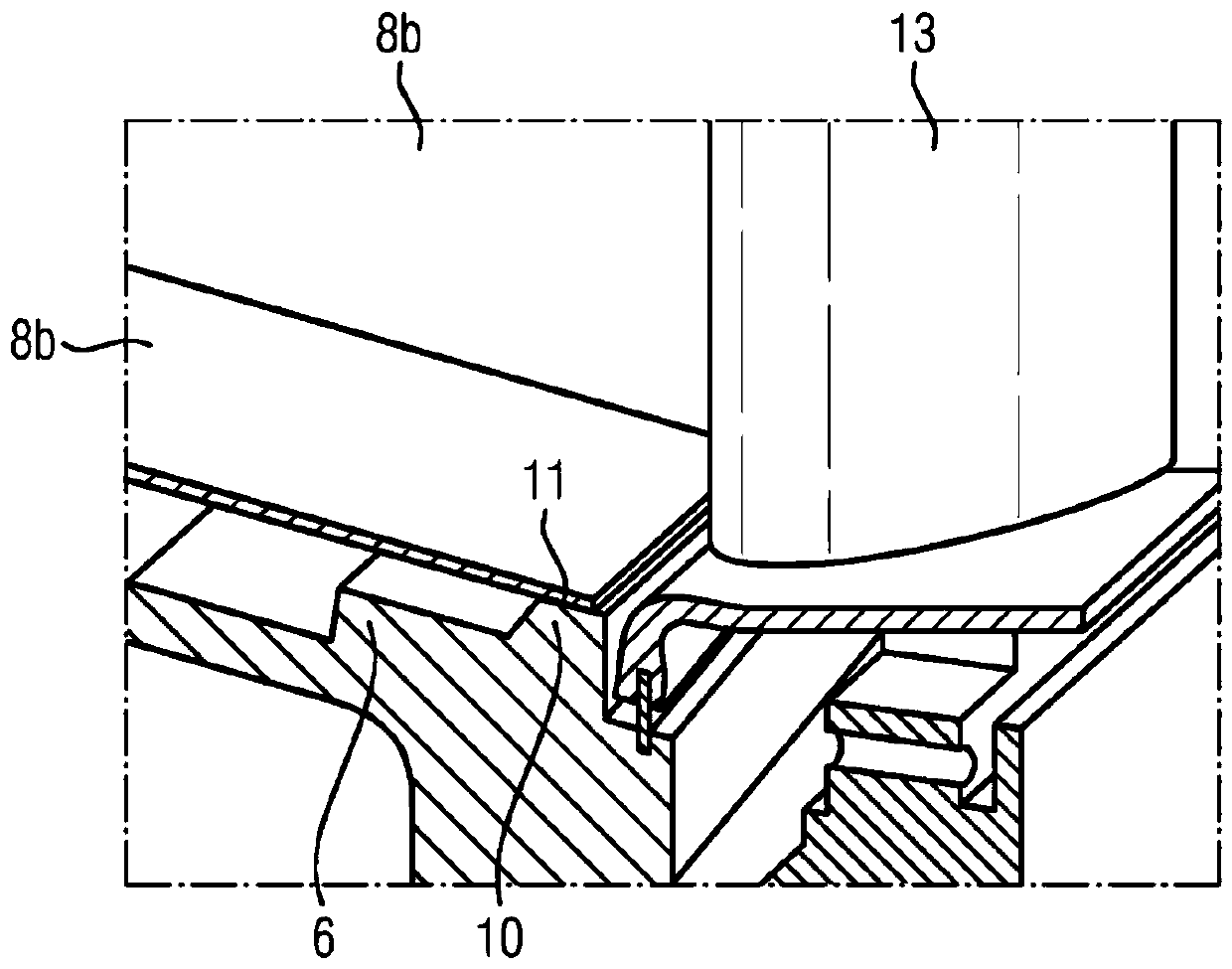

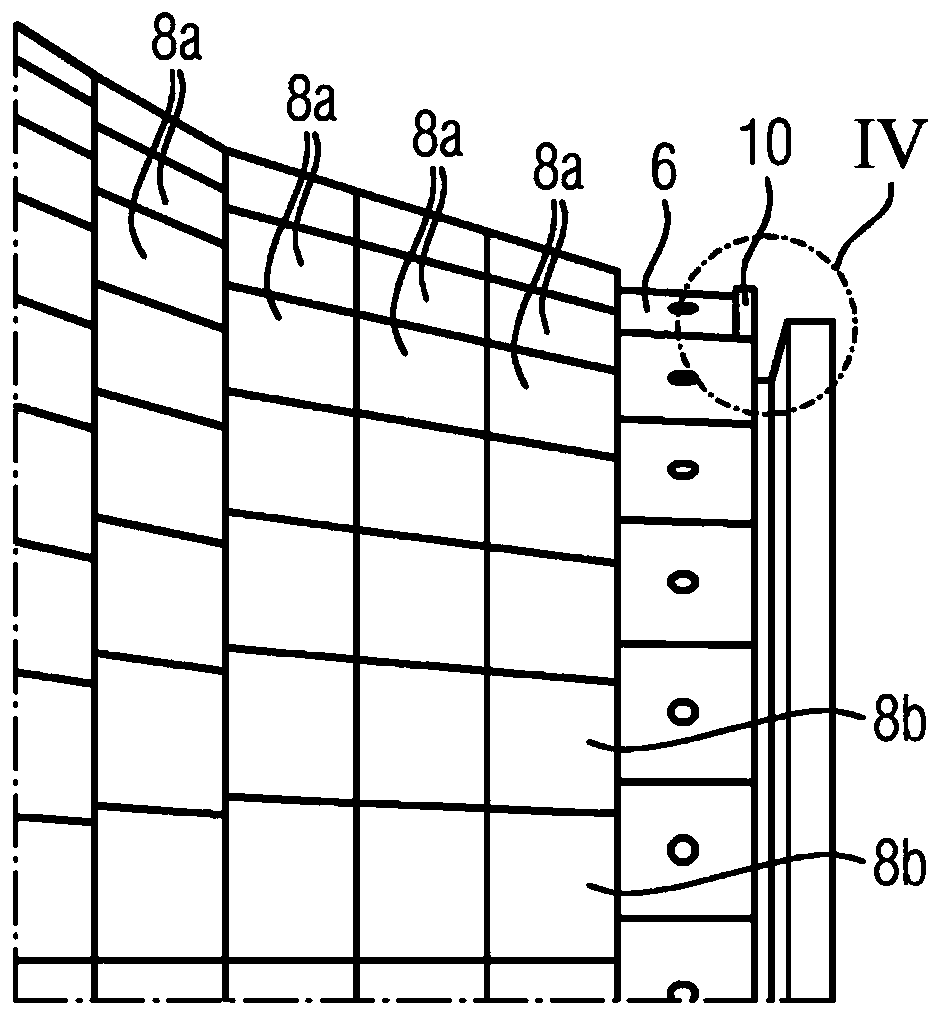

[0028] The gas turbine 1 comprises a rotor 2 having a shaft 3 on which is arranged or fastened a plurality of axially adjacent rows 4 of turbine rotor blades of the turbine region of the gas turbine 1 and a plurality of adjacent rows of the compressor region. Set of compressor rotor blade rows 5. Furthermore, the gas turbine 1 comprises a funnel-shaped hub 6 extending around the shaft 3 , which is arranged between the turbine region and the compressor region and decreases in diameter in the direction of the turbine rotor blade row 4 and thus in the downstream direction. Small. The hub 6 is oriented concentrically with respect to the shaft 3 with a radial annular gap and is held stationary on the housing 7 of the gas turbine 1 so that it does not rotate with the shaft 3 . A plurality of annular rows of heat shielding elements 8a, 8b are fastened axially adjacent to the outer side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com