Control method and system for outlet moisture content of cut tobacco drying procedure

A control method and control system technology, which is applied in the field of control of outlet moisture content, can solve problems such as unstable control of moisture content changes and large influence of subjective experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

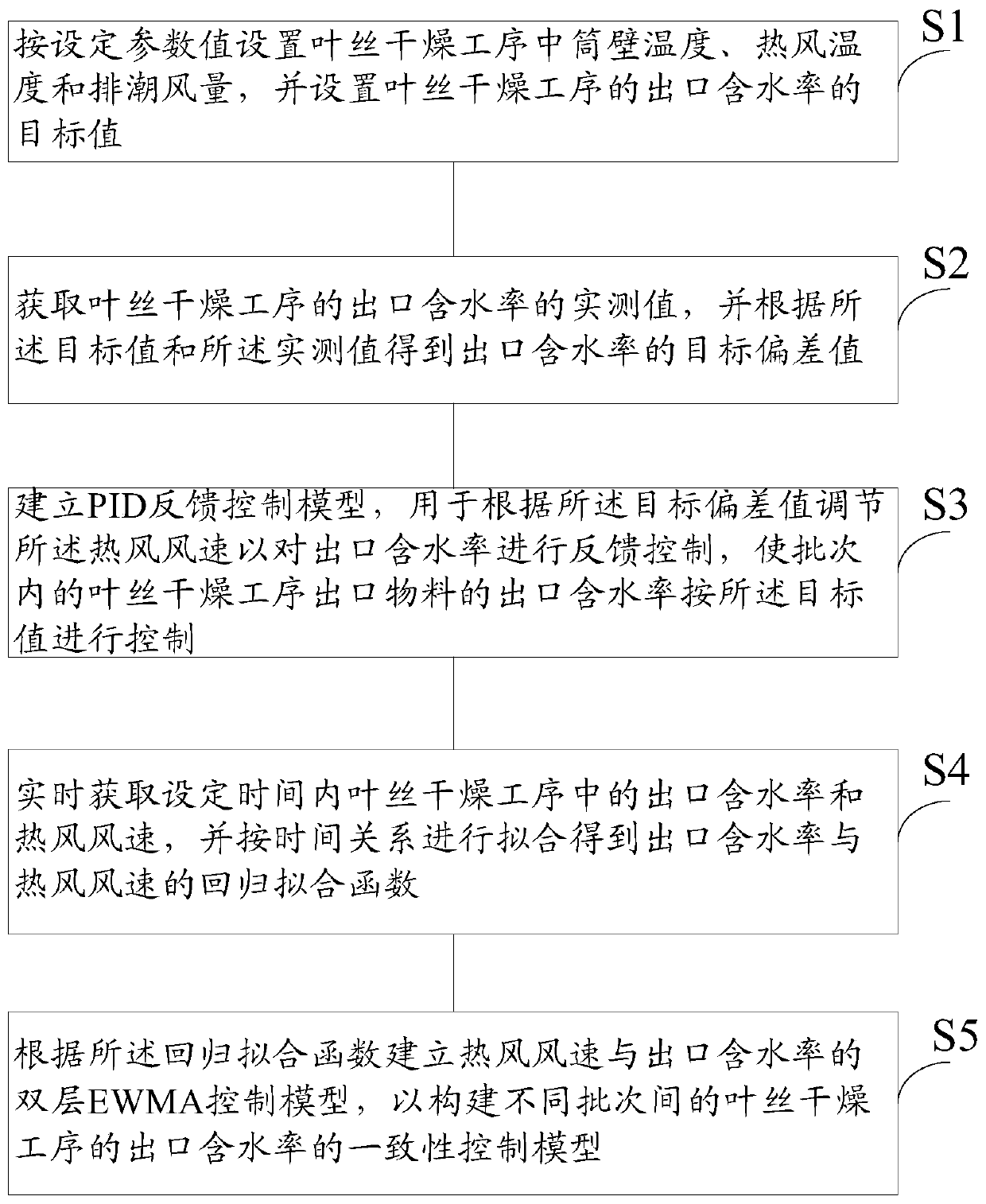

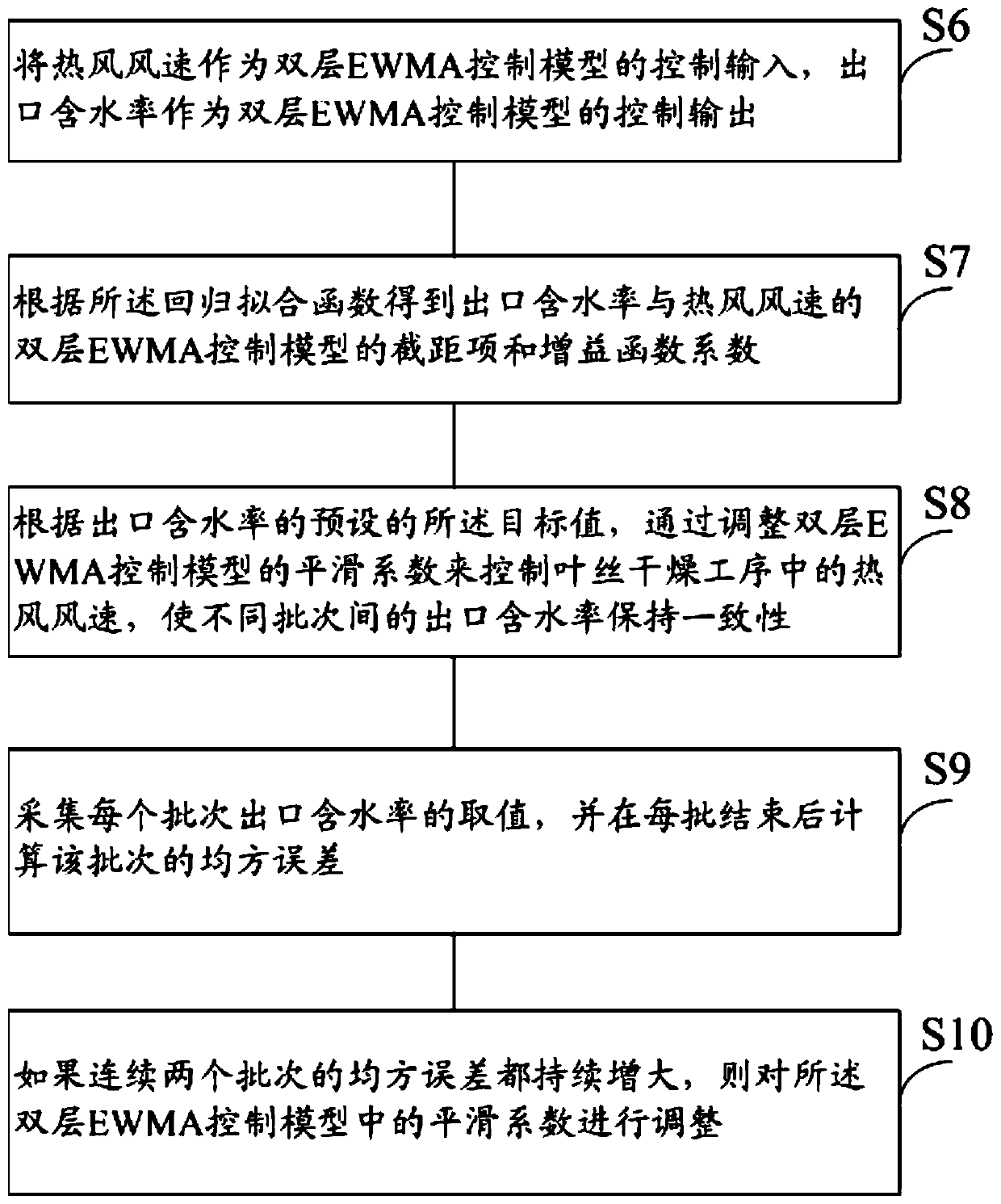

[0053] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

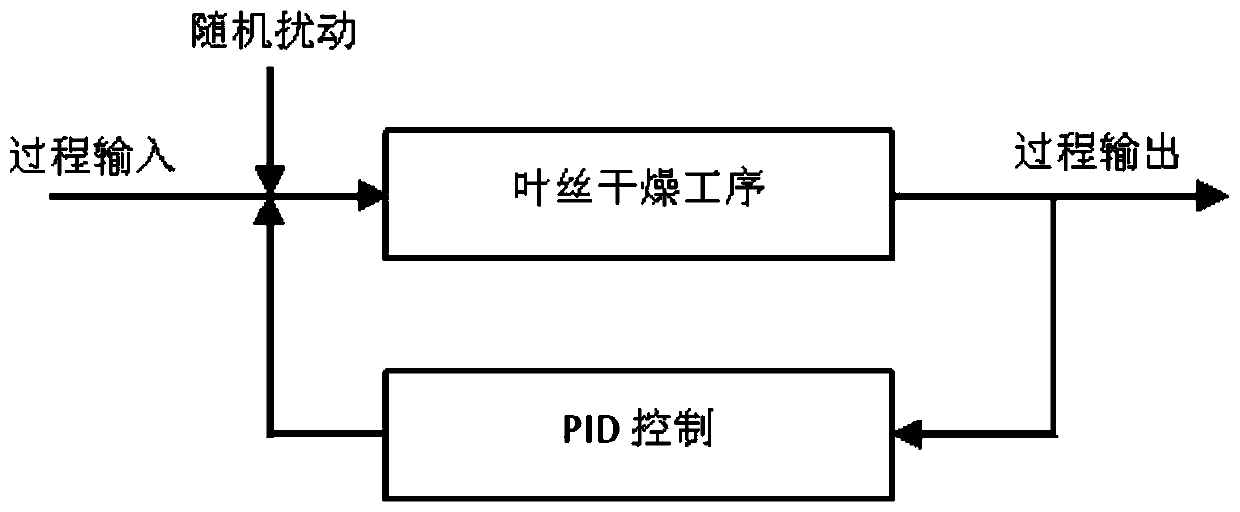

[0054] Aiming at the problem that the outlet moisture content control in the current leaf shred drying process is greatly affected by the subjective experience of the operator, and the consistency of different batches is low. The invention provides a method and system for controlling the outlet water content of the shredded leaves drying process. In the same batch, the PID feedback control model is set to adjust the hot air velocity to control the outlet water content, so as to solve the problem of the outlet materials in the existing shredded leaves drying process. The change control of the moisture content is unstable and greatly affected by the subjective experience of the operator. It can improve the batch co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com