Finned pipe type heat exchanger pipe inserting mechanism

A finned tube heat exchanger technology, applied in the field of highly automated production equipment, can solve the problems of many pipelines, low processing efficiency, uncontrollable, etc., and achieve the effects of avoiding manual operation, improving production efficiency, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

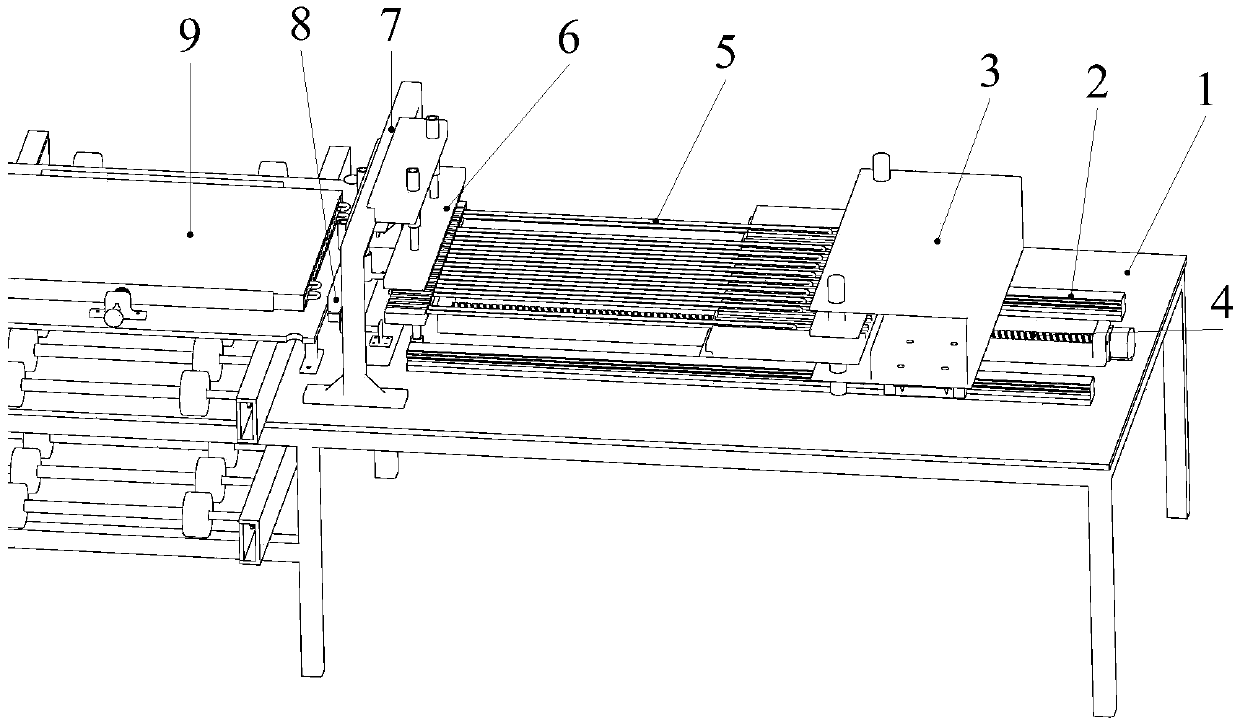

[0023] The invention provides an automatic intubation device, which is particularly suitable for the intubation of heat pipes with closely arranged heat sinks, for example, it is suitable for the intubation process of heat pipes in the assembly and production process of finned tube heat exchangers.

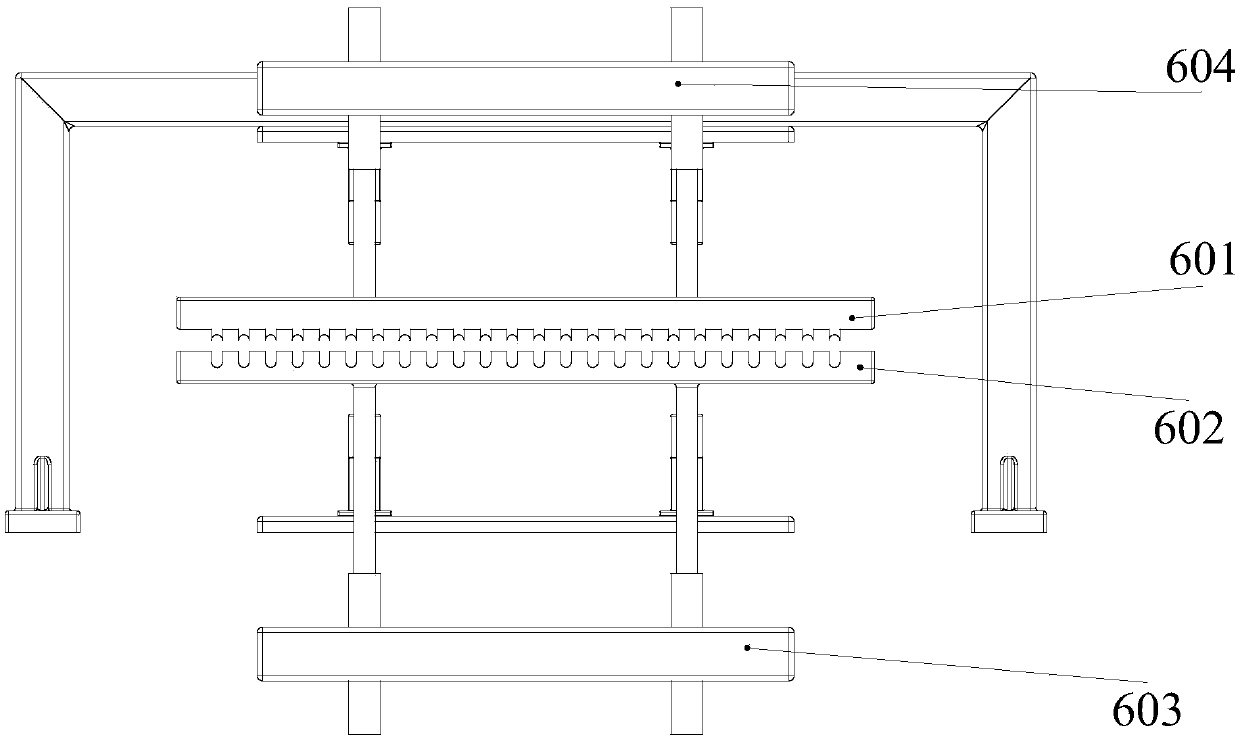

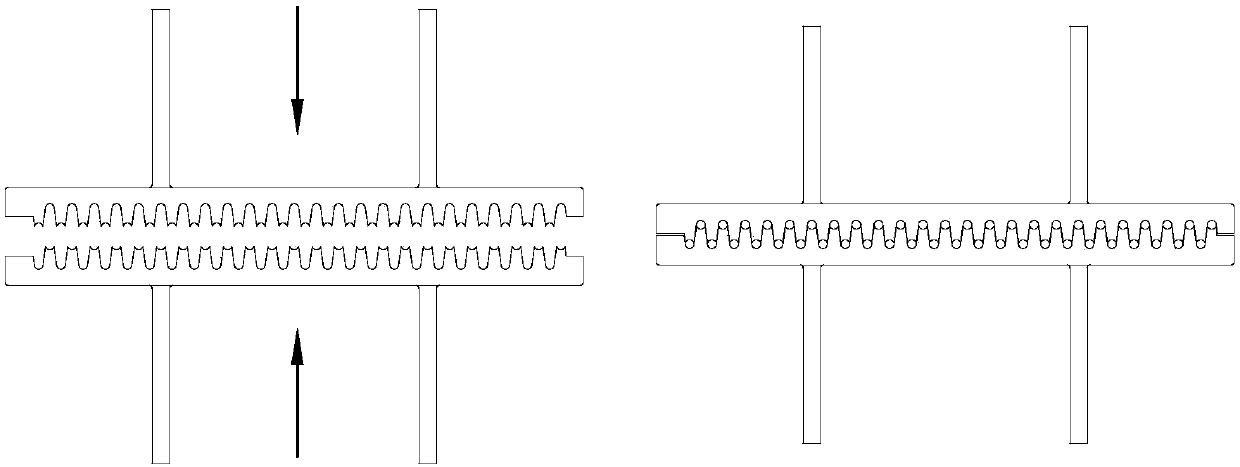

[0024] refer to figure 1 , figure 2 , Figure 5 , a row of U-shaped tubes has been placed between the tube placement groove 304 and the lower tooth plate 602 at the previous station. Next, the lead screw motor guide rail 4 drives the push tube assembly 3 to move for a certain distance in the direction of the heat exchanger 9 to be intubated. 302 presses against the U-shaped tube 5, and cooperates with the tube placement groove 304 to limit the vertical direction of the U-shaped tube 4. Then the guide rail 4 of the screw motor drives the pushing tube assembly 3 to move toward the heat exchanger 9 to be intubated, and the pushing tube plate 306 pushes the U-shaped tube 5 to inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com