Force control abrasive belt grinding machine

A grinding machine and grinding machine technology, applied in belt grinders, grinding machine parts, grinding machines, etc., can solve the problems of complicated time-consuming, increase business costs, etc., to ensure processing quality, reduce costs and time, and work efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

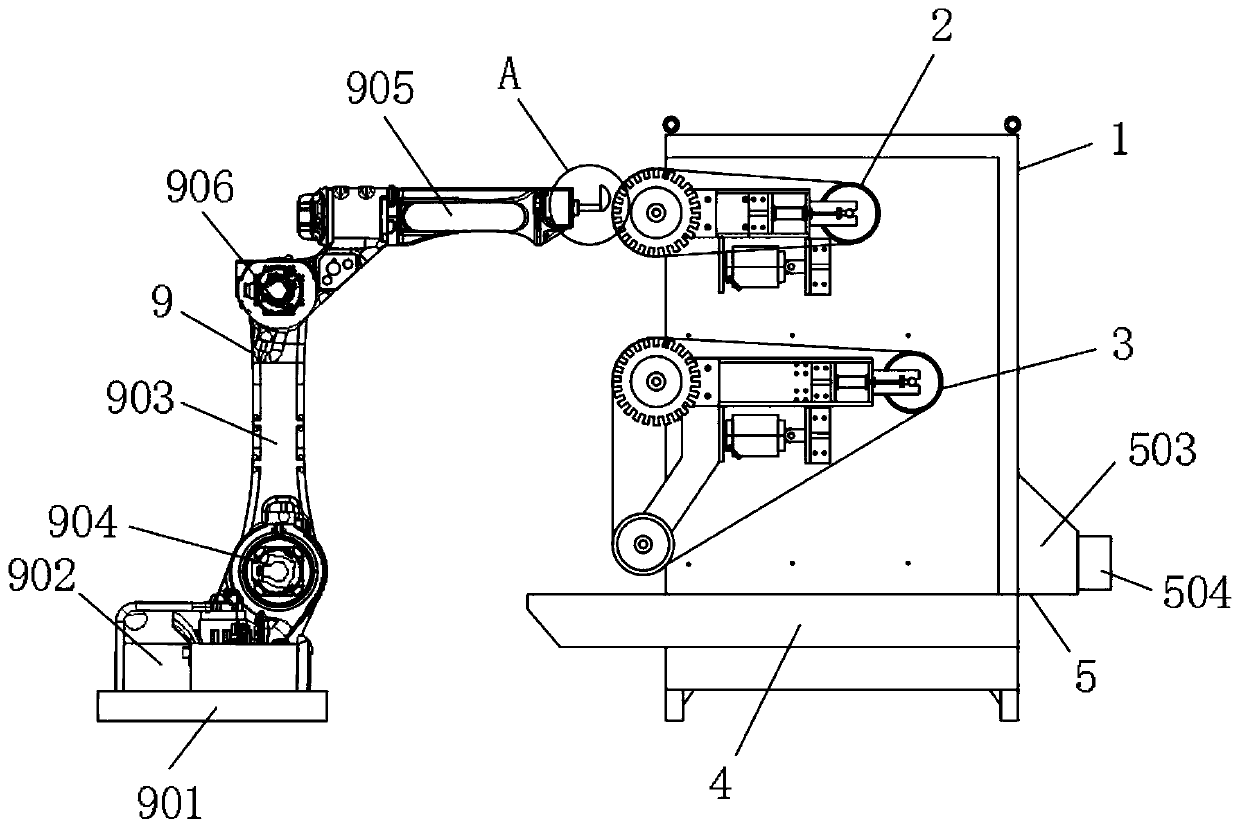

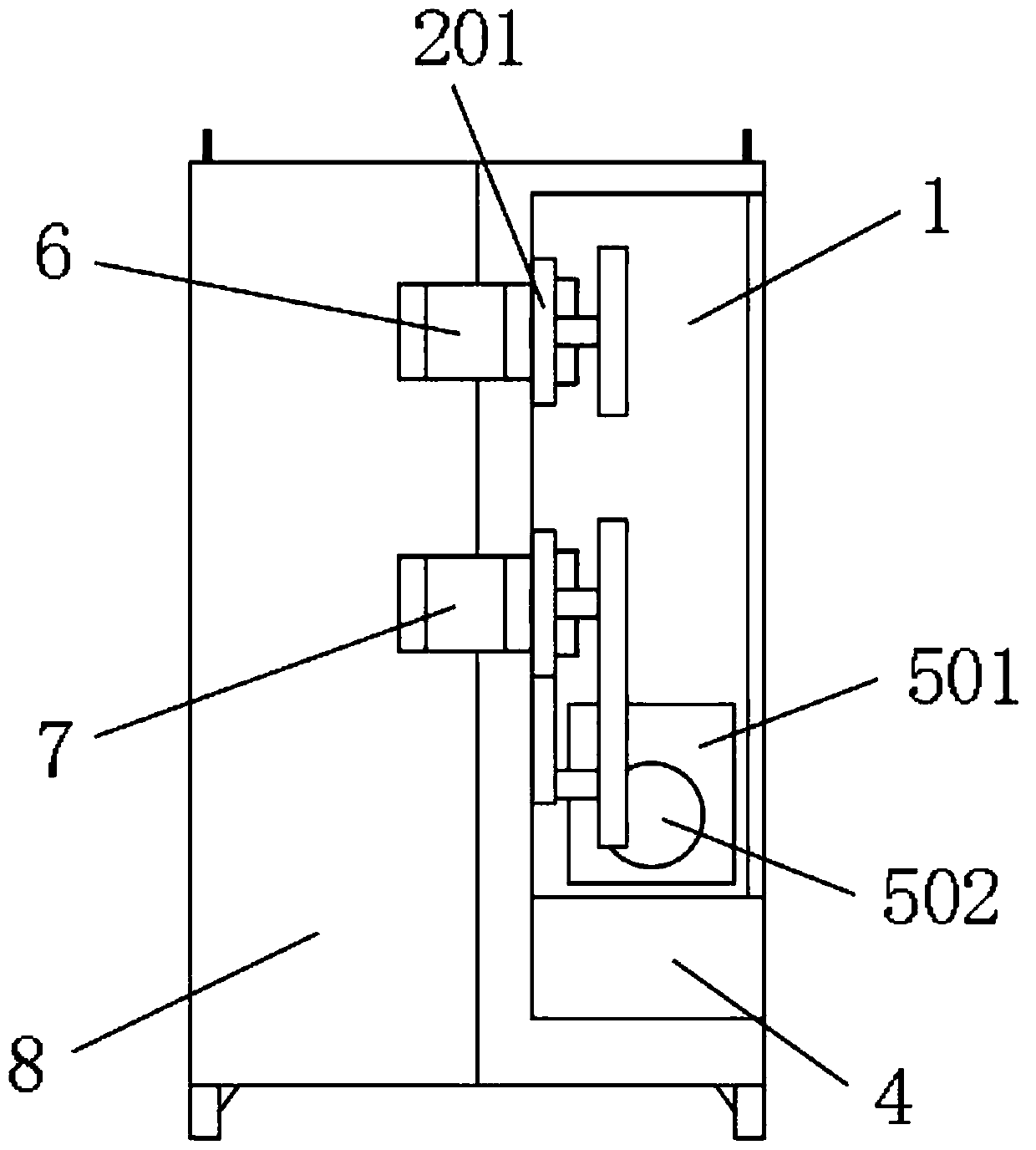

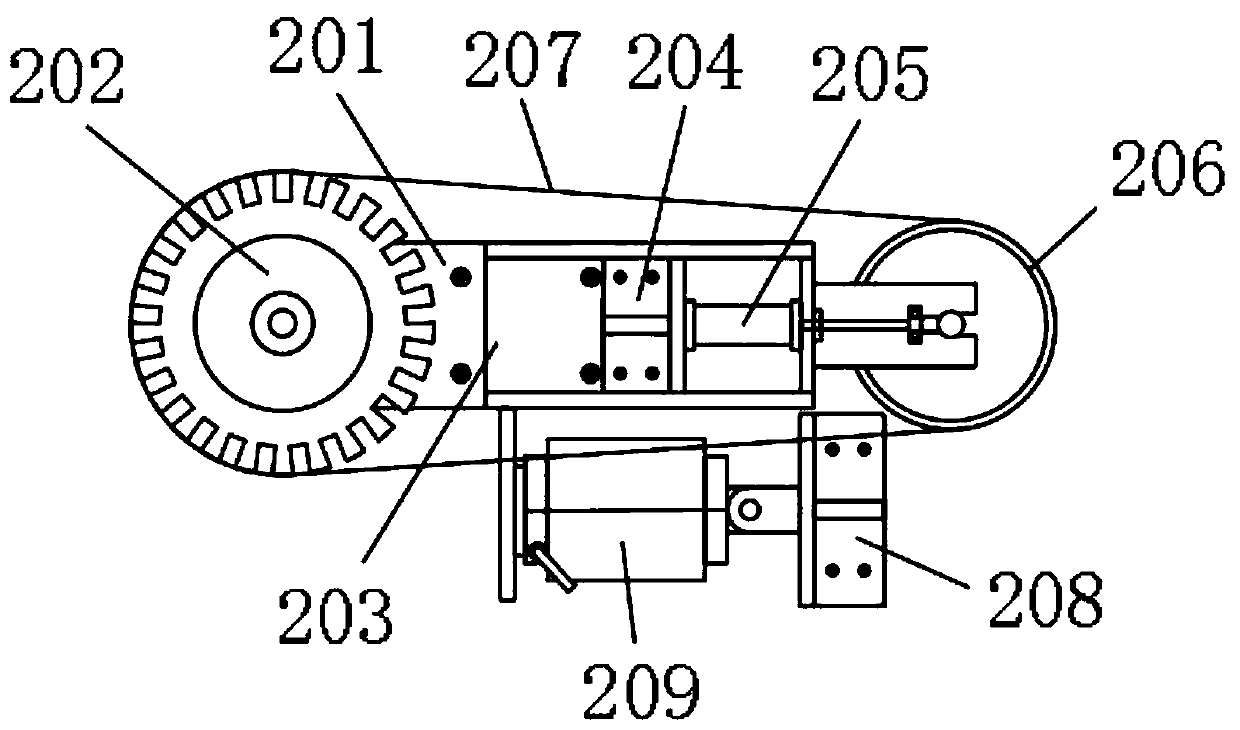

[0029] Such as Figure 1-6 As shown, the embodiment of the present invention provides a force-controlled abrasive belt sander, including a sander body 1, an upper belt mechanism 2 is provided on the top of the outer surface of the front end of the sander body 1, and the bottom of the outer surface of the front end of the sander body 1 is provided There is a lower sand belt mechanism 3, the bottom of the center of the sander body 1 is equipped with a water tank 4 corresponding to the upper sand belt mechanism 2 and the lower sand belt mechanism 3, and the outer wall of the sander body 1 is provided with the upper sand belt mechanism 2 The dust suction mechanism 5 corresponding to the lower belt mechanism 3, the rear end of the grinder body 1 is provided with an electrical control cabinet 8, one side of the grinder body 1 is provided with a robot feeding mechanism 9, and the top of the robot feeding mechanism 9 A workpiece 10 is provided on one side.

[0030] The upper belt mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com