Robot machining work normal constant force tracking method and device

A technology of robot processing and operation method, applied in the field of robot control and normal constant force tracking in robot processing operations, which can solve the problems of increasing production costs, difficulty in obtaining processing trajectories, and difficulty in normal tracking, and achieves improved force control. Accuracy, avoid cost increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

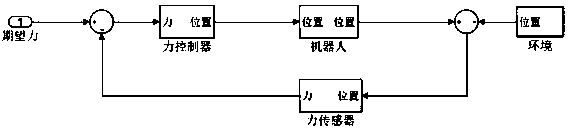

Method used

Image

Examples

Embodiment 1

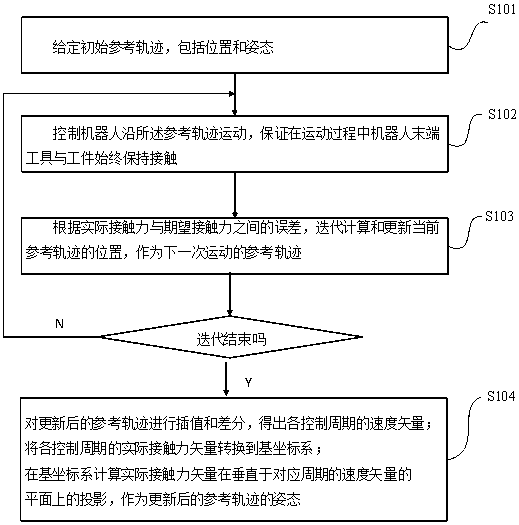

[0066] Such as figure 2 As shown, the robot processing operation normal direction constant force tracking method package in this embodiment

[0067] Include the following steps:

[0068] Step S101: Given an initial reference trajectory, including position and attitude

[0069] That is, given a rough reference trajectory X r , including position and attitude, where the attitude refers to the attitude direction of the end-processing tool of the robot.

[0070] Optionally, the initial reference trajectory can be obtained through teaching points, model export or traction teaching.

[0071] Step S102: Control the robot to move along the reference trajectory, ensuring that the end tool of the robot is always in contact with the workpiece during the movement.

[0072] Set the robot to move along the reference trajectory, and at the same time turn on the force control function, set appropriate force control parameters, such as reference force, damping, etc., to ensure that the en...

Embodiment 2

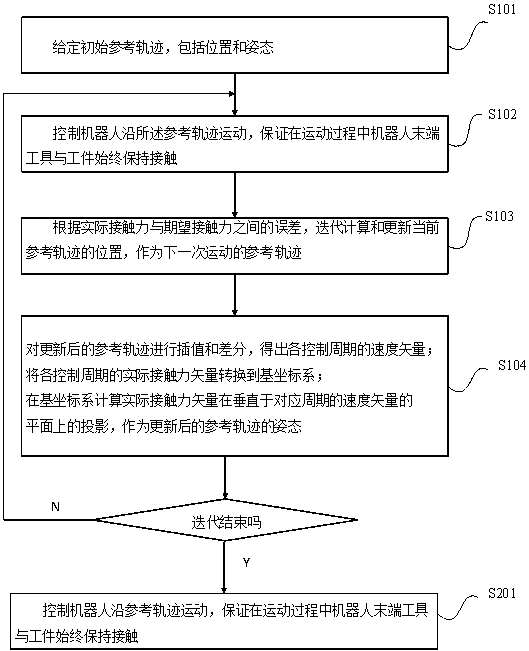

[0115] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that after updating the trajectory position each time, the attitude must be updated. This method increases the amount of computation, but can further improve the accuracy of the reference trajectory.

[0116] Optionally, the robot normal direction constant force tracking method further includes step S201: controlling the motion of the robot according to the reference trajectory obtained after the iteration, including position and posture, for formal workpiece processing.

[0117] attached Figure 4 An embodiment of the constant force tracking device for the normal direction of the robot processing operation according to the present disclosure is provided. Such as Figure 4 As shown, the device includes:

[0118] The force sensor, as a kind of actual contact force acquisition device, is used to measure the actual contact force between the end processing tool of the robot and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com