SMC lining plate and forming die

A technology for forming molds and linings, applied in optics, instruments, optical components, etc., can solve the problems affecting the efficiency of CSP and the life of CSP mirrors, and reduce adhesion, ensure smoothness, and improve bearing strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

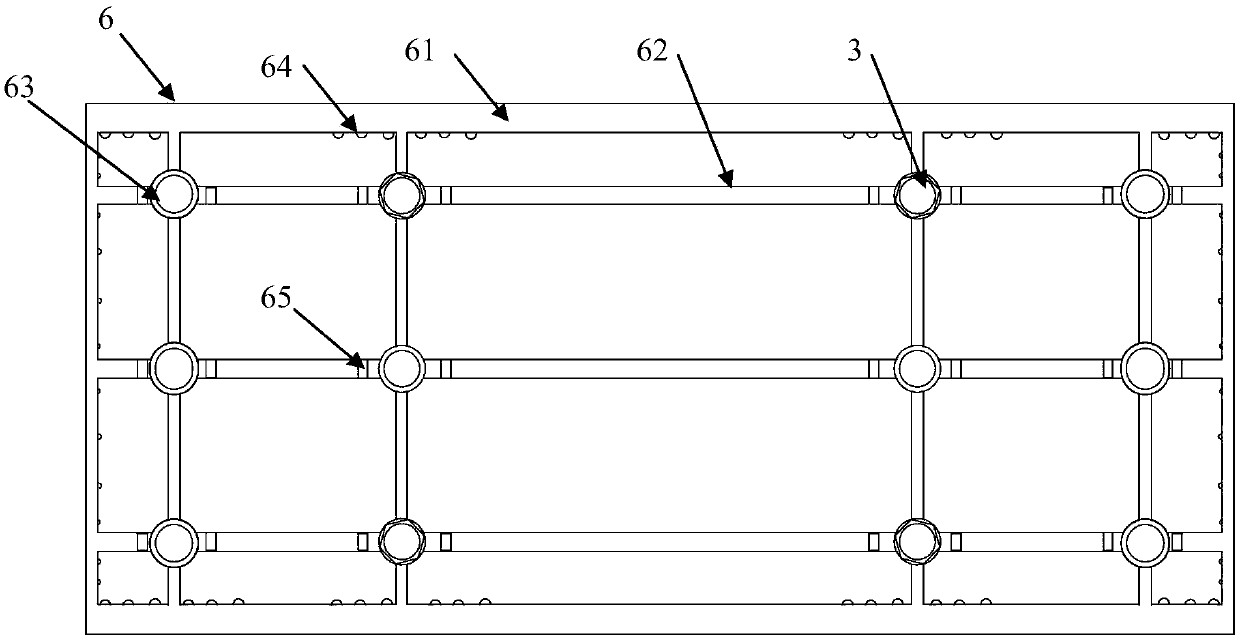

[0028] The SMC liner 6 of the present invention includes an arc-shaped upper surface plate, a peripheral edge 61 integrally molded on the back of the upper surface plate, and a plurality of criss-cross rims integrally molded in the peripheral edge. Plate-shaped reinforcing ribs 62 are integrally molded with nuts 3 at the intersections of some of the reinforcing ribs, and cylindrical reinforcing holes 63 are formed at the intersections of the rest of the reinforcing ribs.

[0029] The SMC liner of the present invention adopts the cavity structure formed by the upper surface plate and the surrounding ring, which meets the overall strength design requirements, and a plurality of criss-crossing plate-shaped reinforcing ribs are arranged inside the surrounding ring to improve The load-bearing strength of the upper surface plate is improved, and reinforcing holes or nuts are set at the intersection of the reinforcing ribs, which can effectively meet the subsequent assembly requiremen...

Embodiment 2

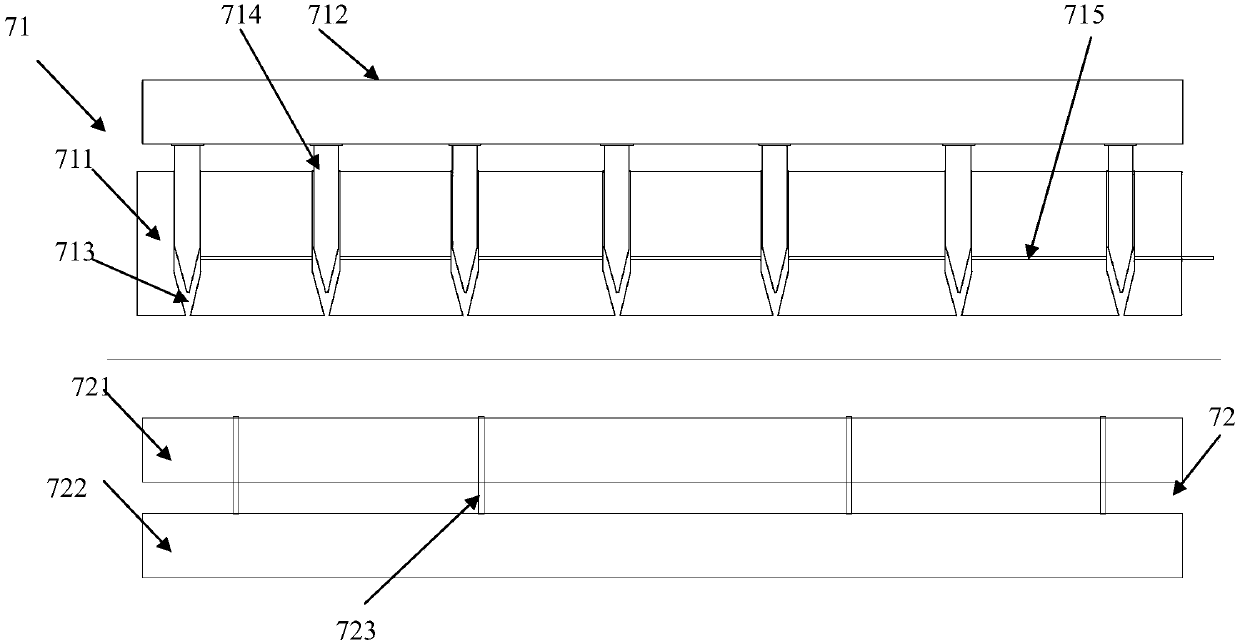

[0033] The molding die for preparing the SMC liner of the present invention includes an upper template 71 and a lower template 72,

[0034] The upper template includes a upper template 711 and an upper ejector plate 712 located above the upper template. The upper template is provided with a plurality of through air holes 713. The upper template is provided with a plurality of The upper blocking rod 714 used to seal the air hole, the air hole is controllably communicated with the compressed air source through the air channel 715;

[0035] The lower template includes a lower template 721 and a lower ejector plate 722 arranged below the lower template. The lower template is provided with a plurality of thimble holes, and the lower ejector plate is provided with a The ejector rod 723 corresponding to the thimble hole.

[0036] Specifically, the SMC liner is formed by a hydraulic press. The working pressure of the hydraulic press is 2000T, and the pressure is maintained for 2-4 mi...

Embodiment 3

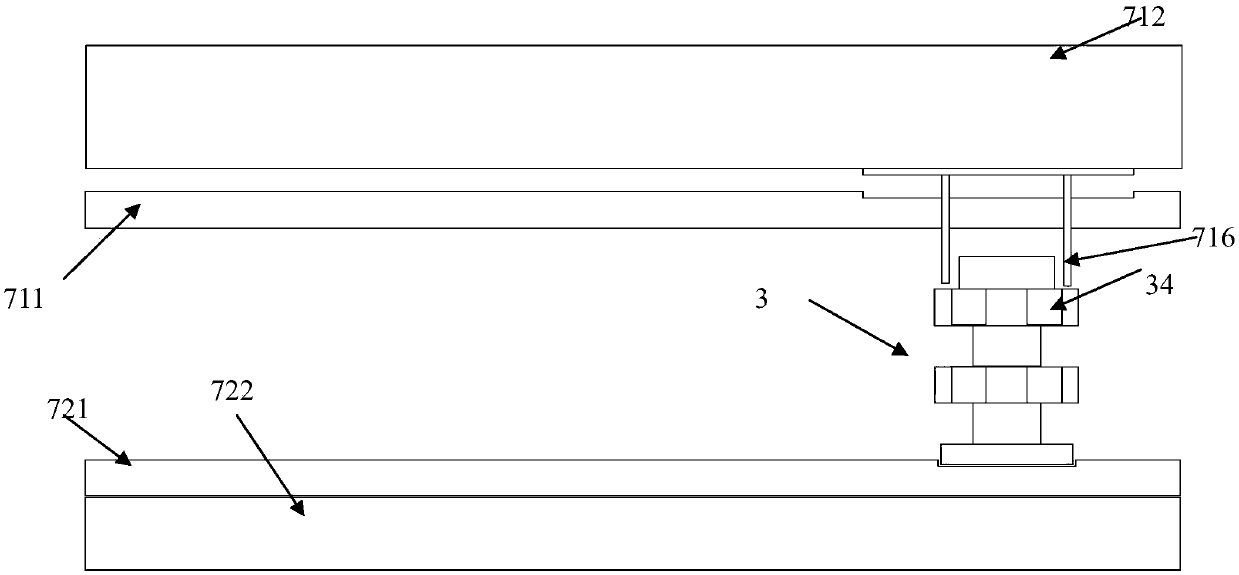

[0041] Further, in order to prevent the SMC material in the molten state from flowing into the cavity of the nut during molding, a nut positioning cavity for accommodating the nut 3 is provided on the lower mold plate, and a nut positioning cavity for accommodating the nut 3 is provided on the upper molded bar. The corresponding pressure rod perforation of the top ring, the nut pressure pin 716 that can match through the pressure rod perforation and be pressed on the top ring is arranged on the upper thimble plate, such as the nut pressure pin 716 There are four needles. Four nut pressing pins are used to press the nut and the lower plate tightly to reduce the generation of gaps, which can effectively prevent the entry of SMC and avoid the inconvenience of subsequent installation. Of course, the nut pressing pins can also be directly arranged on the upper mold plate.

[0042] Preferably, it also includes a SMC liner board retrieving mechanism, which includes a frame and a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com