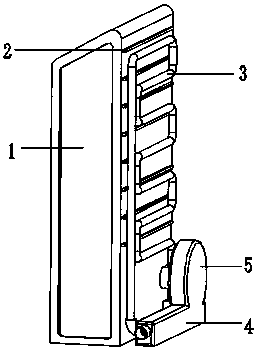

Water-cooled water-driven cooling charging pile

A charging pile, water-driven technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of inability to adapt to heat dissipation conditions, heat can not be discharged in time, etc., to achieve safe use, easy to operate, not easy to leak water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

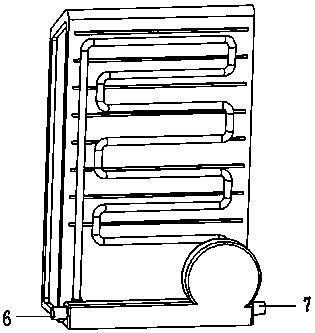

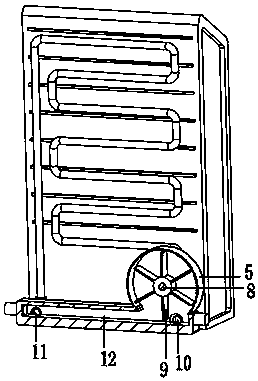

[0027] A specific application of this embodiment is: the present invention continuously pours water into the water channel 4, part of the water flow enters the water storage pipe 10, flows into the inner cavity of the water storage tank 17, and passes the water through the water channel 4, so that the water flow impacts the blades 9, The blade 9 can be rotated so that the impeller main shaft 8 can continue to rotate, the rotation of the impeller main shaft 8 drives the driving shaft 16 to rotate, and the meshing between the driving gear 19 and the driven gear 21 enables water to be sucked into the gap between the teeth. It is brought into the water pipe 3 from both sides of the pump water tank 14. Through the reduction of the gap between the teeth, the water is pumped out to realize the water intake, and the water flows through the water pipe 3, so that the flow of water in the water pipe 3 passes through the heat conduction effect of the heat conduction plate 2 , so that the h...

Embodiment 2

[0029] A specific application of this embodiment is: the present invention connects the water channels 4 of each group of charging piles 1 through an external water pipe, and by continuously pouring water into the water channel, part of the water flows into the water storage pipe 10 and flows into the inner cavity of the water storage tank 17. Through the water flowing through the water channel 4, the water flow impacts the blade 9, so that the blade 9 can rotate, so that the impeller main shaft 8 can continue to rotate, the rotation of the impeller main shaft 8 drives the driving shaft 16 to rotate, and the driving gear 19 and the driven gear The meshing of 21 enables water to be sucked into the gap between the teeth, and is brought into the water pipe 3 from both sides of the pump water tank 14. Through the reduction of the gap between the teeth, the water is pumped out to realize water intake, and the water flows through the water pipe 3, so that The flow of water in the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com