Dispensing tank for compound fertilizer anti-blocking agent production

An anti-caking agent and batching tank technology, which is applied in the field of batching tanks, can solve the problems of inconvenient cleaning, inconvenient pouring of ingredients, and easy adhesion of ingredients to the inner wall of the tank, so as to achieve the effect of convenient dumping and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

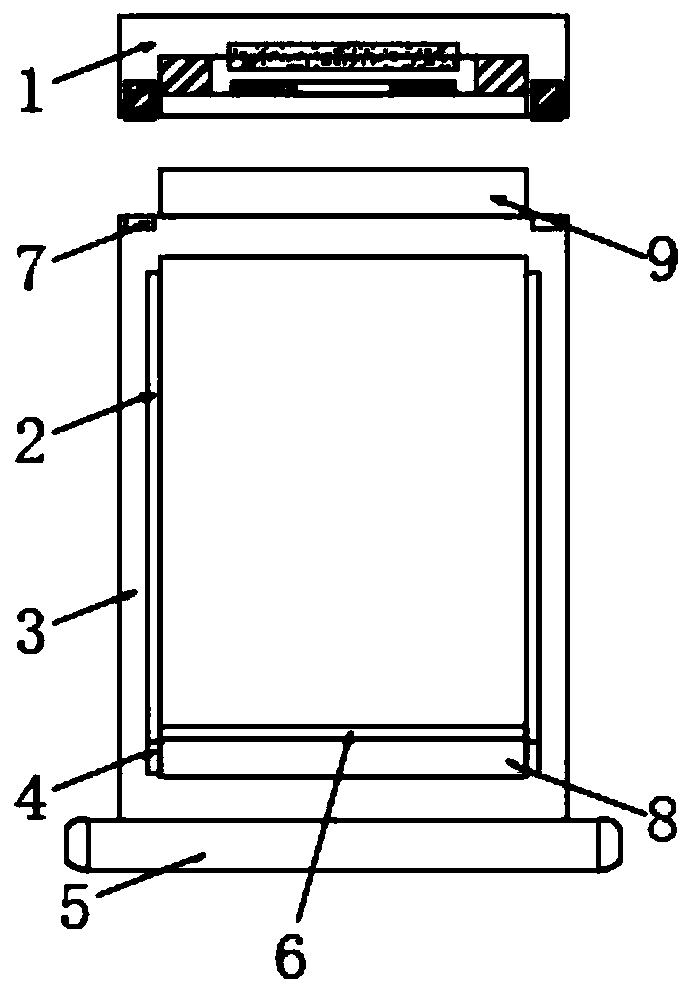

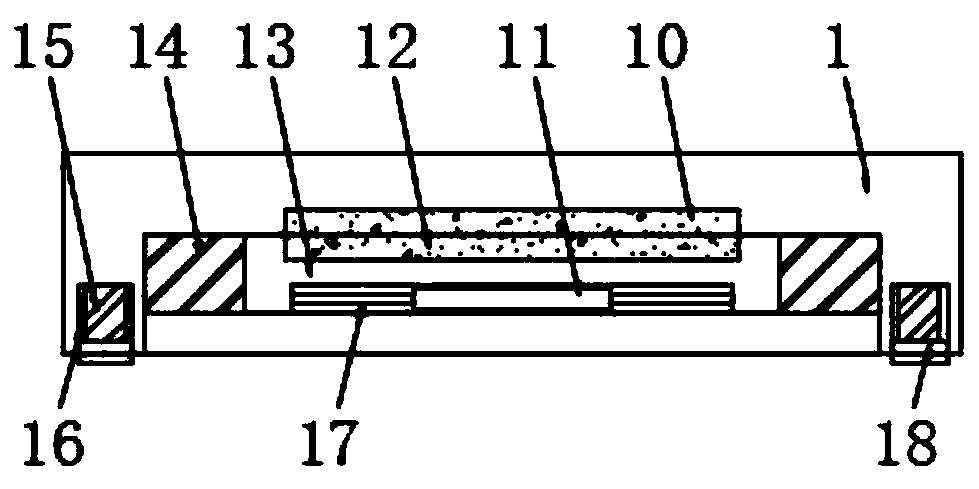

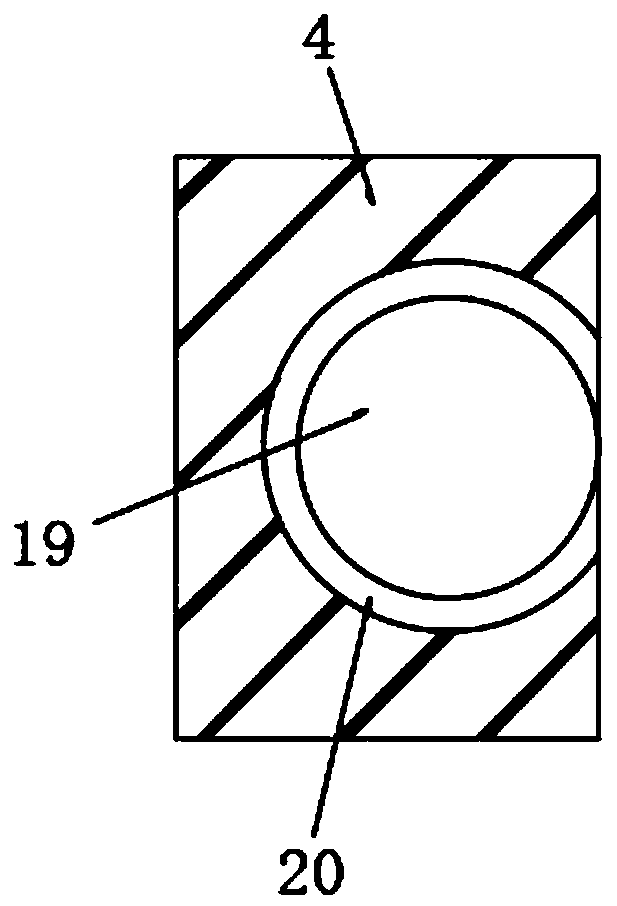

[0024] see Figure 1-4 , a batching tank for the production of a compound fertilizer anti-caking agent, comprising a batching tank body 3 and a batching tank cover 1, the batching tank cover 1 is located on the top of the batching tank body 3, and the upper end of the batching tank body 3 is fixedly connected with a tank body convex The edge 9, the bottom of the batching tank body 3 is fixedly connected with the tank body support 5, the middle position of the inner upper wall of the batching tank cover 1 is fixedly connected with the upper suction piece 10, and the inner side of the batching tank cover 1 is installed with an inner cleaning plate 13, The middle position of the upper surface of the inner cleaning plate 13 is fixedly connected with the lower suction piece 12 adapted to the upper suction piece 10, and the middle position of the bottom of the inner cleaning plate 13 is provided with a grid bar slot 17, and the inside of the grid bar slot 17 A hand-held grille 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com