Skin care emulsion filling equipment with stirring function

The technology of filling equipment and skin care lotion is applied in the field of skin care lotion filling equipment, which can solve the problems of lotion precipitation and uneven canning of lotion-like skin care cosmetics, and achieve the effect of reducing the amount of sticking to the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

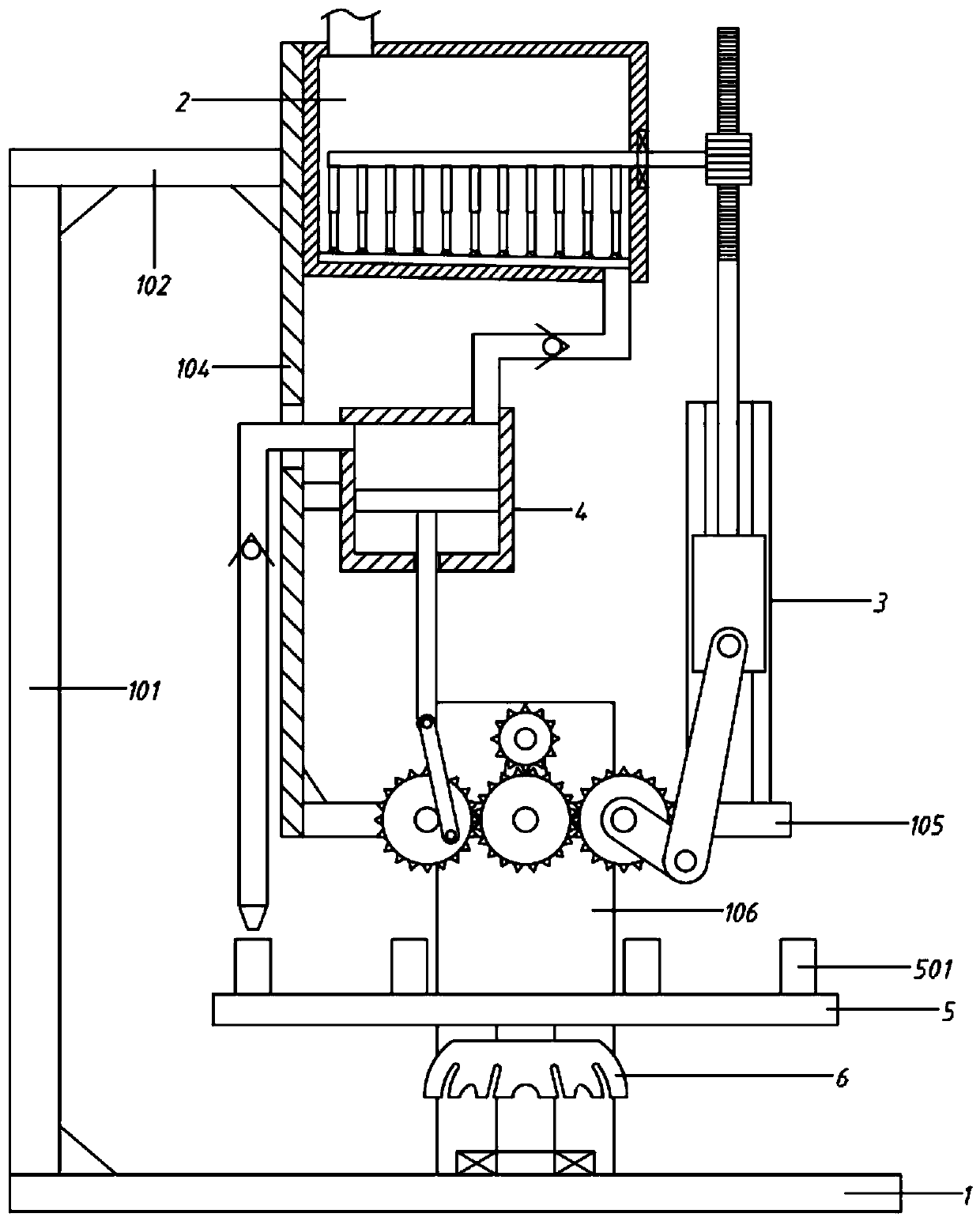

[0048] A skin care lotion filling equipment with a stirring function, including a mixing drum 2, a reciprocating component 3 and a support;

[0049] The bracket includes a No. 1 support plate 104 and a No. 2 support plate 105. The No. 1 support plate 104 is vertically arranged, and the No. 2 support plate 105 is horizontally arranged on the right side of the No. 1 support plate 104. The left end of the No. 2 support plate 105 is fixed to the No. 1 support plate. plate 104;

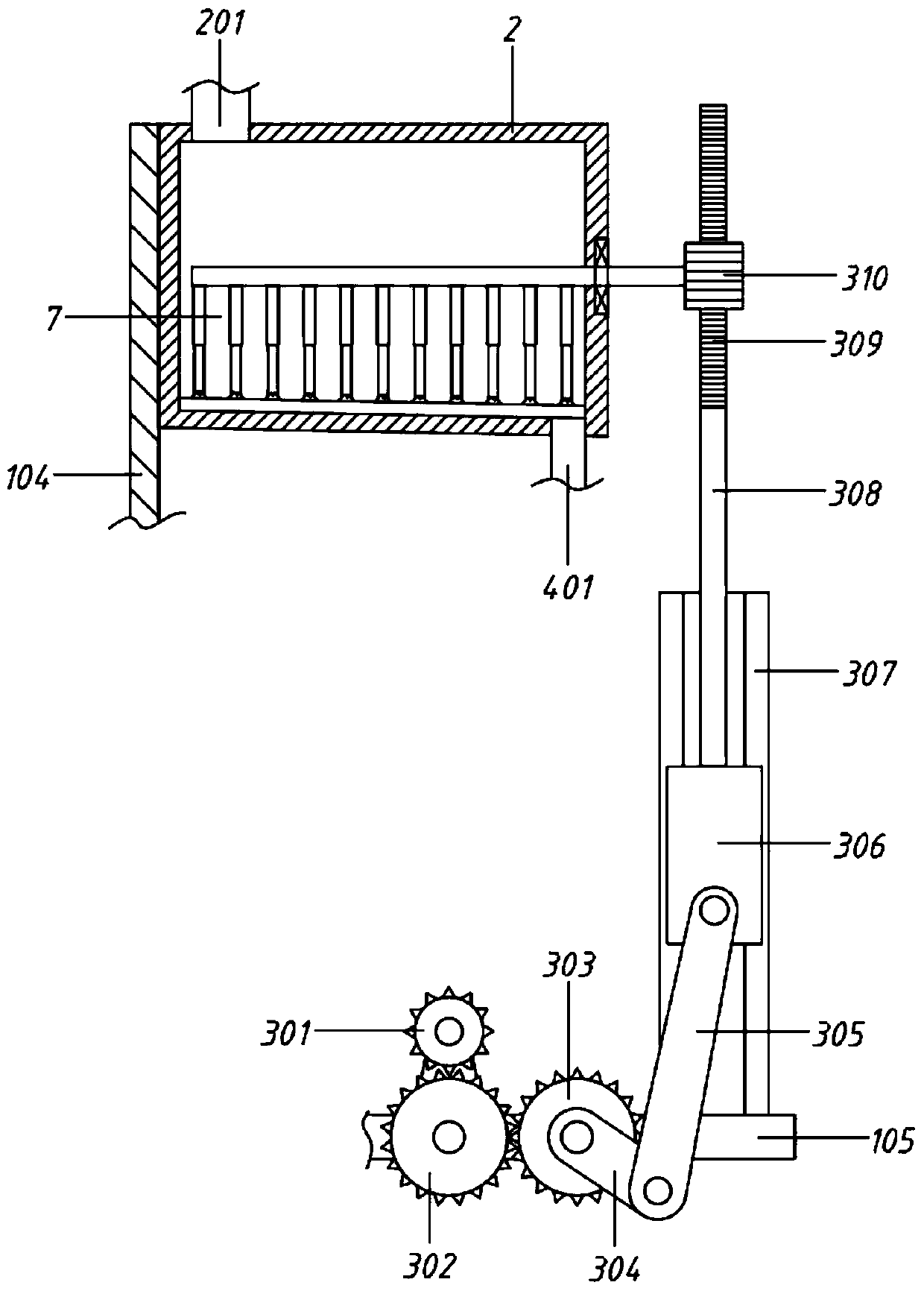

[0050] The mixing drum 2 is fixed on the top of the right side of No. 1 support plate 104; the mixing drum 2 is installed horizontally, the top is connected with the liquid inlet pipe 201, and the bottom is connected with the catheter 401;

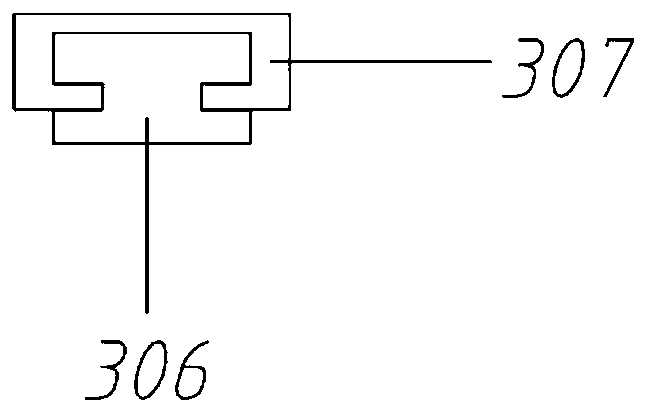

[0051] Reciprocating assembly 3 includes servo motor 103, driving gear 301, No. 1 gear 302, No. 2 gear 303, No. 1 rod 304, No. 2 rod 305, slider 306 and slide rail 307; Servo motor 103 is housed on No. 2 support plate 105 , the output end of the servo motor 103 protru...

Embodiment 2

[0058] A skin care lotion filling equipment with a stirring function, including a mixing drum 2, a reciprocating component 3 and a support;

[0059] The bracket includes a No. 1 support plate 104 and a No. 2 support plate 105. The No. 1 support plate 104 is vertically arranged, and the No. 2 support plate 105 is horizontally arranged on the right side of the No. 1 support plate 104. The left end of the No. 2 support plate 105 is fixed to the No. 1 support plate. plate 104;

[0060] The mixing drum 2 is fixed on the top of the right side of No. 1 support plate 104; the mixing drum 2 is installed horizontally, the top is connected with the liquid inlet pipe 201, and the bottom is connected with the catheter 401;

[0061] Reciprocating assembly 3 includes servo motor 103, driving gear 301, No. 1 gear 302, No. 2 gear 303, No. 1 rod 304, No. 2 rod 305, slider 306 and slide rail 307; Servo motor 103 is housed on No. 2 support plate 105 , the output end of the servo motor 103 protru...

Embodiment 3

[0067] A skin care lotion filling equipment with a stirring function, including a mixing drum 2, a reciprocating component 3 and a support;

[0068] The bracket includes a No. 1 support plate 104 and a No. 2 support plate 105. The No. 1 support plate 104 is vertically arranged, and the No. 2 support plate 105 is horizontally arranged on the right side of the No. 1 support plate 104. The left end of the No. 2 support plate 105 is fixed to the No. 1 support plate. plate 104;

[0069] The mixing drum 2 is fixed on the top of the right side of No. 1 support plate 104; the mixing drum 2 is installed horizontally, the top is connected with the liquid inlet pipe 201, and the bottom is connected with the catheter 401;

[0070] Reciprocating assembly 3 includes servo motor 103, driving gear 301, No. 1 gear 302, No. 2 gear 303, No. 1 rod 304, No. 2 rod 305, slider 306 and slide rail 307; Servo motor 103 is housed on No. 2 support plate 105 , the output end of the servo motor 103 protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com