Forsterite well block formula and preparation method thereof

The technology of olivine seat and forsterite is applied in the field of forsterite seat brick formulation and preparation, and can solve the problems such as the deterioration of the quality of the tundish seat brick, the easy infiltration of molten steel around the seat brick, the accident of steel penetration at the seat brick part, and the like. Achieve improved service life, low cost, reduced damage and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

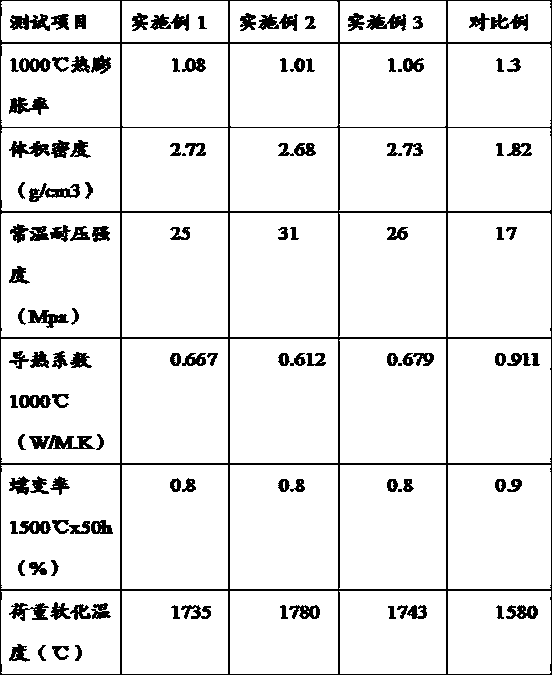

Examples

Embodiment 1

[0035] A formula for a forsterite seat brick, comprising forsterite particles, magnesia-chrome synthetic powder, clay powder, graphite, an inorganic binder, and a liquid resin, the percentages by weight are as follows:

[0036] Forsterite Granules 65%

[0037] Magnesium chromium synthetic powder 20%

[0038] Clay powder 5%

[0039] Graphite 1%

[0040] Inorganic binder 5%

[0041] Liquid Resin 4%

[0042] Its preparation method is as follows:

[0043] S1, ingredients; mix forsterite particles, magnesium chromium synthetic powder, clay powder, and graphite according to weight percentage;

[0044] S2, mixing materials; add forsterite particles, inorganic binder, and liquid resin into a high-speed mixer for 10 minutes, then add magnesium-chromium synthetic powder, clay powder, and graphite and mix and mix for 15 minutes to obtain mud, and the temperature reaches Discharge after 30°C;

[0045] S3, trapped material; put the mud material at a constant temperature for 12 hours...

Embodiment 2

[0051] A formula for a forsterite seat brick, comprising forsterite particles, magnesia-chrome synthetic powder, clay powder, graphite, an inorganic binder, and a liquid resin, the percentages by weight are as follows:

[0052] Forsterite Granules 67%

[0053] Magnesium chromium synthetic powder 20%

[0054] Clay powder 5%

[0055] Graphite 1.5%

[0056] Inorganic binder 3%

[0057] Liquid resin 3.5%

[0058] Its preparation method is as follows:

[0059] S1, ingredients; mix forsterite particles, magnesium chromium synthetic powder, clay powder, and graphite according to weight percentage;

[0060] S2, mixing materials; add forsterite particles, inorganic binder, and liquid resin into a high-speed mixer for 15 minutes, then add magnesium-chromium synthetic powder, clay powder, and graphite and mix and mix for 15 minutes to obtain mud, and the temperature reaches Discharge after 40°C;

[0061] S3, trapped material; put the mud material at a constant temperature for 18 h...

Embodiment 3

[0067] A formula for a forsterite seat brick, comprising forsterite particles, magnesia-chrome synthetic powder, clay powder, graphite, an inorganic binder, and a liquid resin, the percentages by weight are as follows:

[0068] Forsterite Granules 70%

[0069] Magnesium chromium synthetic powder 19%

[0070] Clay powder 4%

[0071] Graphite 1%

[0072] Inorganic binder 3%

[0073] Liquid Resin 3%

[0074] Its preparation method is as follows:

[0075] S1, ingredients; mix forsterite particles, magnesium chromium synthetic powder, clay powder, and graphite according to weight percentage;

[0076] S2, mixing materials; add forsterite particles, inorganic binder, and liquid resin into a high-speed mixer for 20 minutes, then add magnesium-chromium synthetic powder, clay powder, and graphite and mix and mix for 15 minutes to obtain mud, and the temperature reaches Discharge after 60°C;

[0077] S3, trapped material; put the mud material at a constant temperature for 124 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com