Support structure for conveying pipe with damping structure

A technology for conveying pipelines and bracket structures, which is applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc. Guaranteed shock absorption stability and reliability, good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

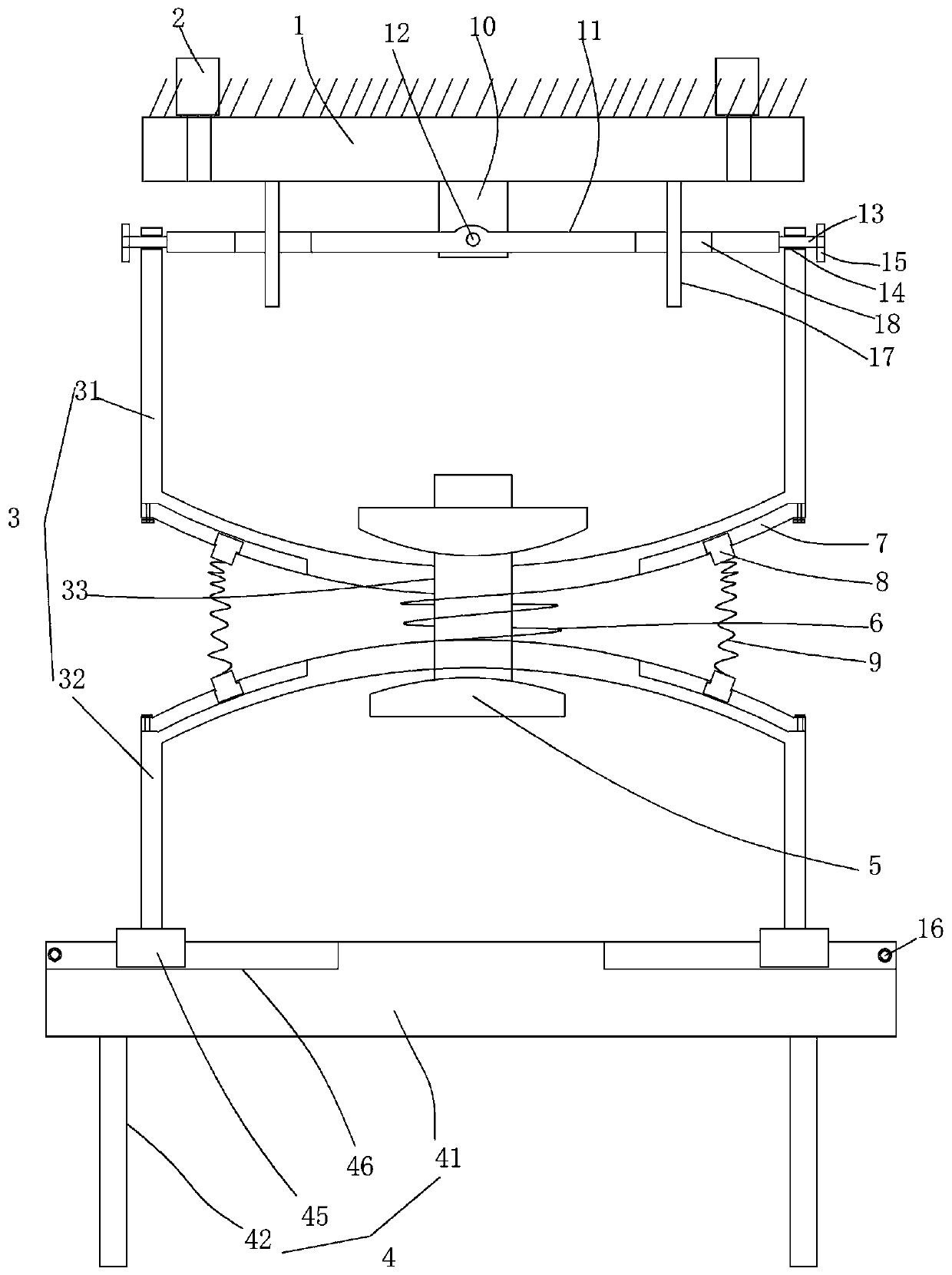

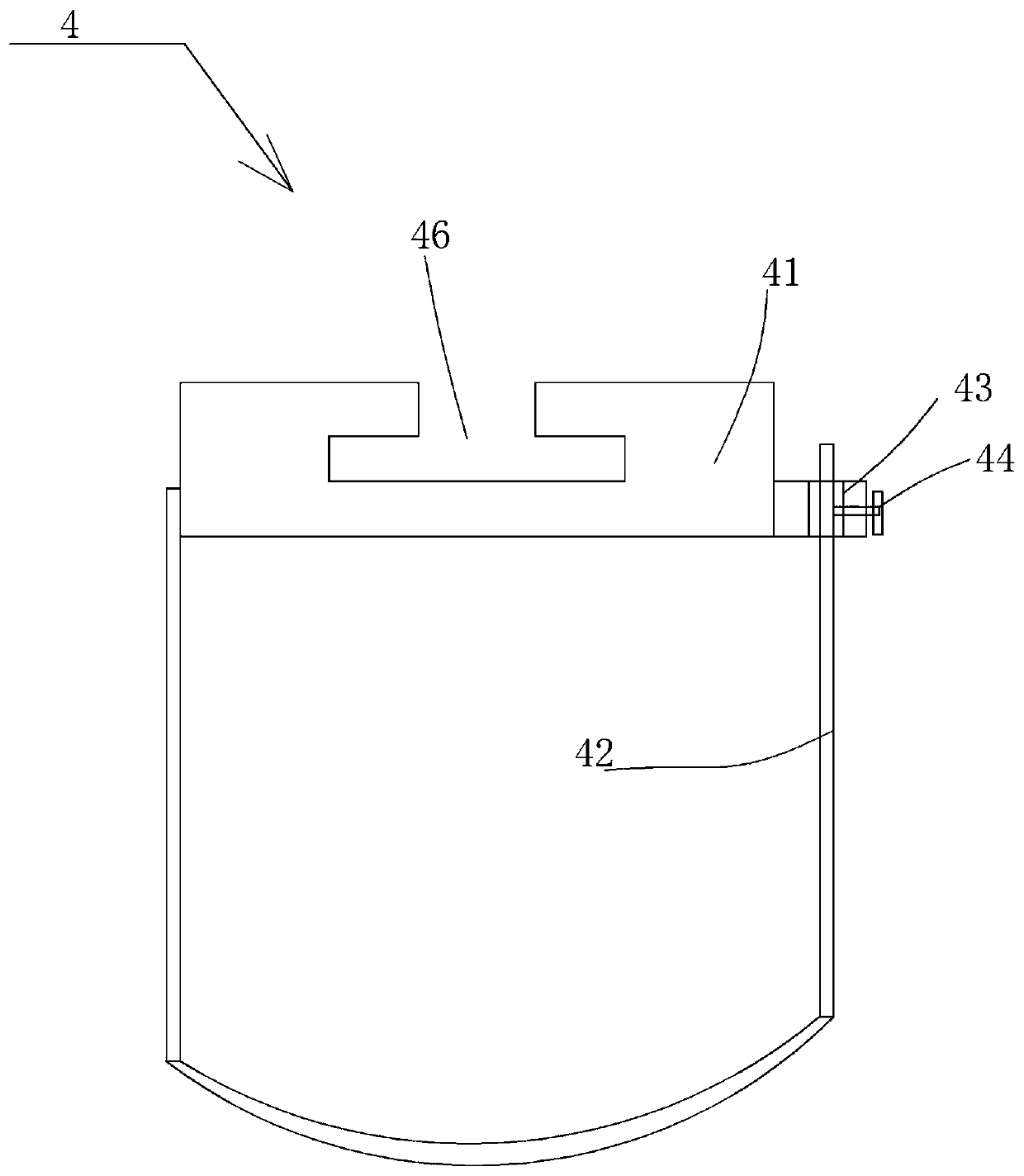

[0015] figure 1 with figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a sectional structure diagram of the pressure plate in the present invention.

[0016] See figure 1 with figure 2 , a support structure for pipelines with a shock-absorbing structure, including a mounting base 1, on which an expansion bolt 2 is arranged, and the mounting base is fixed on the bottom surface of the ceiling or the cross bar of the gantry frame through expansion bolts during use , a shock absorbing structure 3 is fixed on the mounting seat and a pipe positioning structure 4 is fixed at the bottom end of the shock absorbing structure, the shock absorbing structure 3 includes a U-shaped plate 31 and an n-shaped plate 32, the U The middle part of the crossbar of the shaped plate and the n-shaped plate is provided with a circular hole 33, and a bolt 5 is arranged in the circular hole, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com