A multi-effect reaction furnace for producing PVC and its working method

A technology of a reaction furnace and a reaction chamber, which is applied in the field of multi-effect reaction furnaces for PVC production, can solve problems such as long-term heating, achieve the effects of balancing temperature, achieving sustainability and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

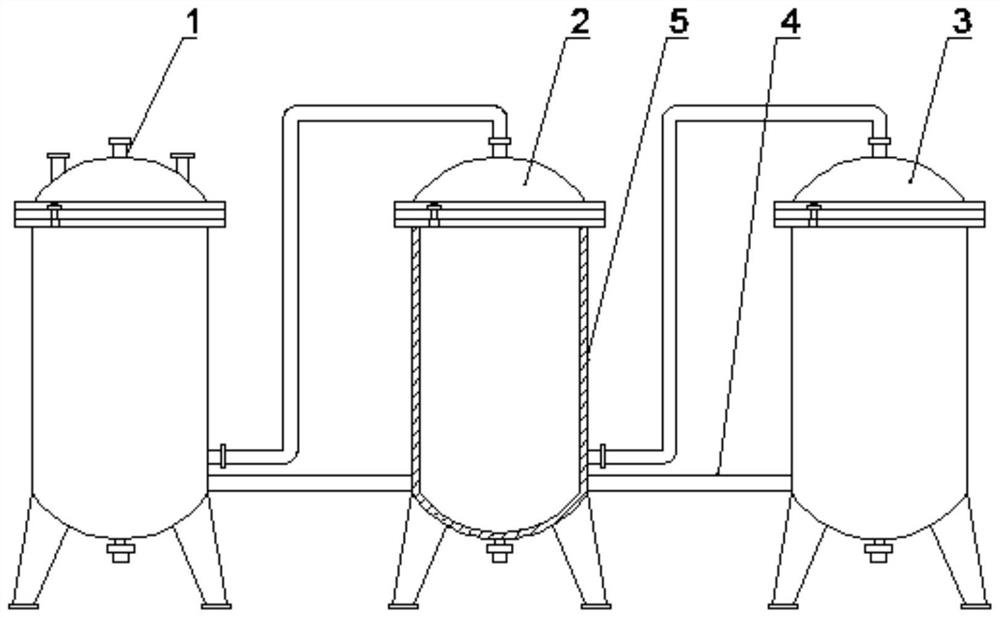

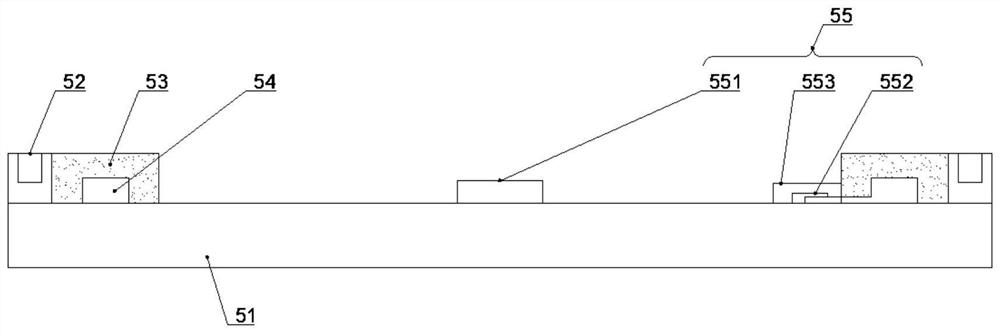

[0039] Such as Figure 1-5 The shown multi-effect reaction furnace for producing PVC includes: a preheating furnace 1, a heating furnace 2, a cooling furnace 3 and a waste heat recovery mechanism 4, a heating furnace 2 is connected to one side of the preheating furnace 1, and the A cooling furnace 3 is connected to the side of the heating furnace 2 away from the preheating furnace 1, and a waste heat recovery mechanism 4 is arranged on the cooling furnace 3, and the waste heat recovery mechanism 4 is connected to the preheating furnace 1;

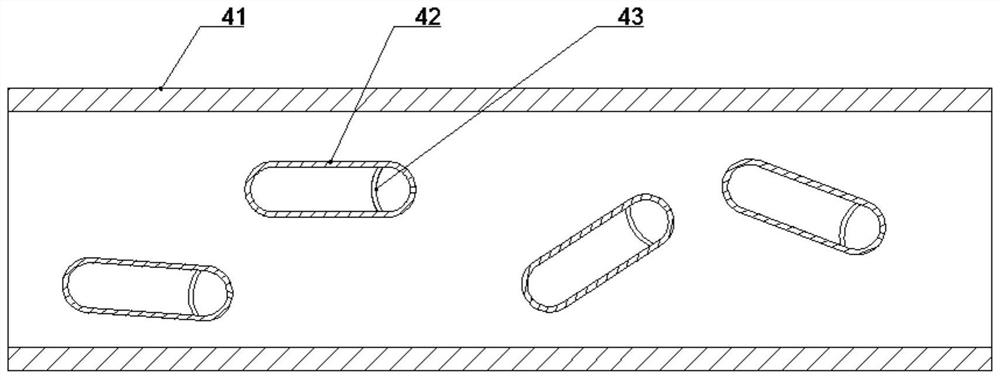

[0040] The waste heat recovery mechanism 4 includes a heat delivery pipe 41 and a heat storage capsule 42, one end of the heat delivery pipe 41 is arranged around the inside of the cooling furnace 3, and the other end of the heat delivery pipe 41 is arranged around the inside of the preheating furnace 1, The heat delivery pipe 41 is ring-shaped, and a heat storage capsule 42 is arranged inside the heat delivery pipe 41, and the heat storage...

Embodiment 2

[0053] Such as figure 1 and 2 The shown multi-effect reaction furnace for producing PVC includes: a preheating furnace 1, a heating furnace 2, a cooling furnace 3 and a waste heat recovery mechanism 4, a heating furnace 2 is connected to one side of the preheating furnace 1, and the A cooling furnace 3 is connected to the side of the heating furnace 2 away from the preheating furnace 1, and a waste heat recovery mechanism 4 is arranged on the cooling furnace 3, and the waste heat recovery mechanism 4 is connected to the preheating furnace 1;

[0054] The waste heat recovery mechanism 4 includes a heat delivery pipe 41 and a heat storage capsule 42, one end of the heat delivery pipe 41 is arranged around the inside of the cooling furnace 3, and the other end of the heat delivery pipe 41 is arranged around the inside of the preheating furnace 1, The heat delivery pipe 41 is ring-shaped, and a heat storage capsule 42 is arranged inside the heat delivery pipe 41, and the heat sto...

Embodiment 3

[0057] Such as figure 1 and 3 The shown multi-effect reaction furnace for producing PVC includes: a preheating furnace 1, a heating furnace 2, a cooling furnace 3 and a waste heat recovery mechanism 4, a heating furnace 2 is connected to one side of the preheating furnace 1, and the A cooling furnace 3 is connected to the side of the heating furnace 2 away from the preheating furnace 1, and a waste heat recovery mechanism 4 is arranged on the cooling furnace 3, and the waste heat recovery mechanism 4 is connected to the preheating furnace 1;

[0058] The waste heat recovery mechanism 4 includes a heat delivery pipe 41 and a heat storage capsule 42, one end of the heat delivery pipe 41 is arranged around the inside of the cooling furnace 3, and the other end of the heat delivery pipe 41 is arranged around the inside of the preheating furnace 1, The heat delivery pipe 41 is ring-shaped, and a heat storage capsule 42 is arranged inside the heat delivery pipe 41, and the heat sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com