Stress measurement method and stress measurement light path device

A technology of stress measurement and optical path, which is applied in the direction of measuring device, measuring force, and the measurement of the change force of the optical properties of the material when it is stressed, which can solve the problems of limited applicability, affecting the accuracy and error of calculation, etc. , to achieve the effect of convenient calculation and enhanced applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] See attached figure 1 and image 3 , the stress measurement method that the present invention provides for the parallel photoelastic method of photoelastic material sample and digital image correlation method, it comprises the following steps:

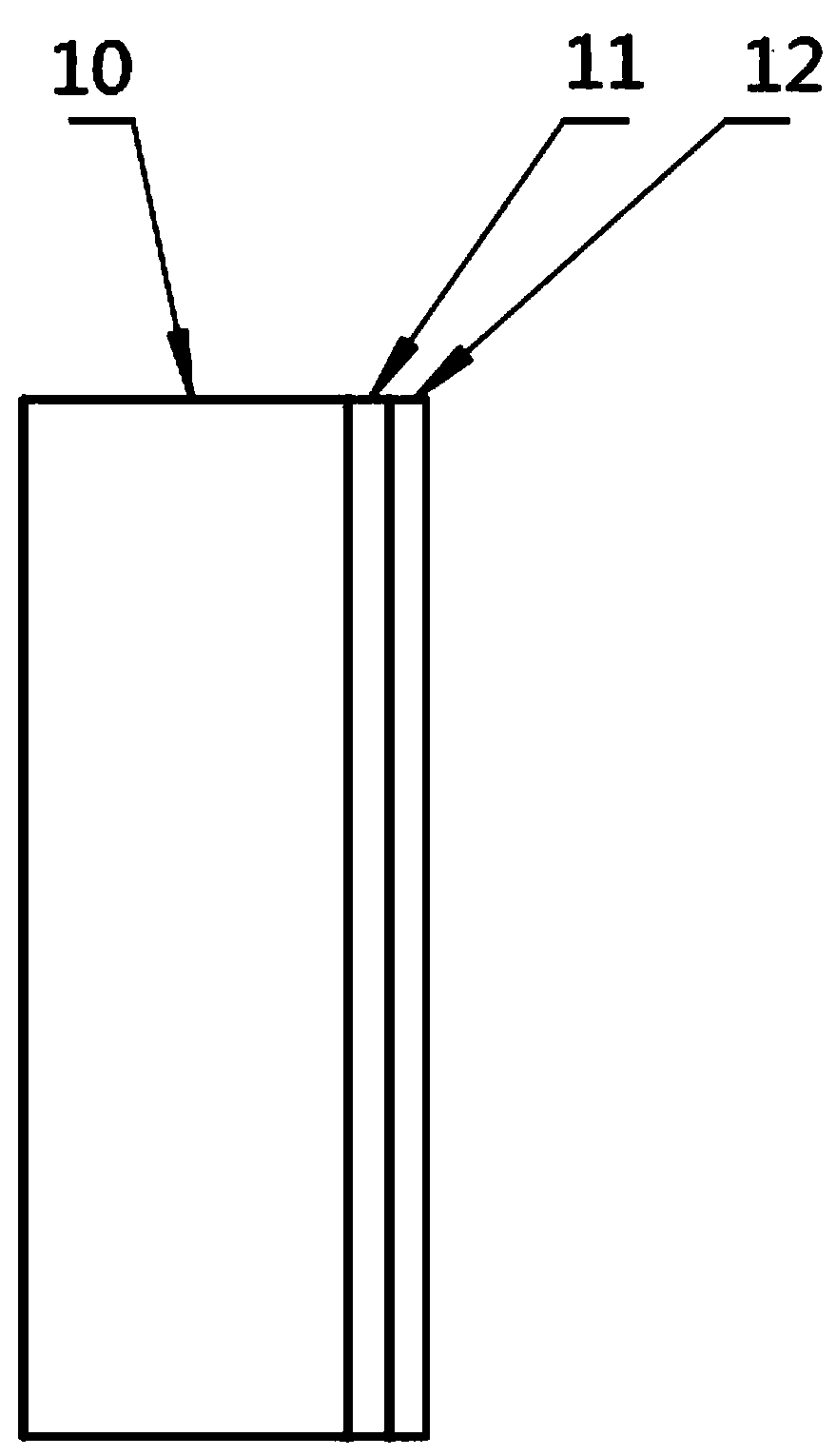

[0040] (1) A photoelastic material sample body 10 made of a single photoelastic material is set, and a coating structure is arranged on the outside of the sample body, and the coating structure includes a reflective coating 11 coated on one side of the sample body and is arranged on The speckle pattern 12 outside the reflective coating 11; the above-mentioned reflective coating 11 can reflect an image, and when stress measurement is performed, the reflective coating 11 will reflect the image after passing through the photoelastic sample, and perform a reflective photoelastic experiment The principal stress difference on one side can be obtained;

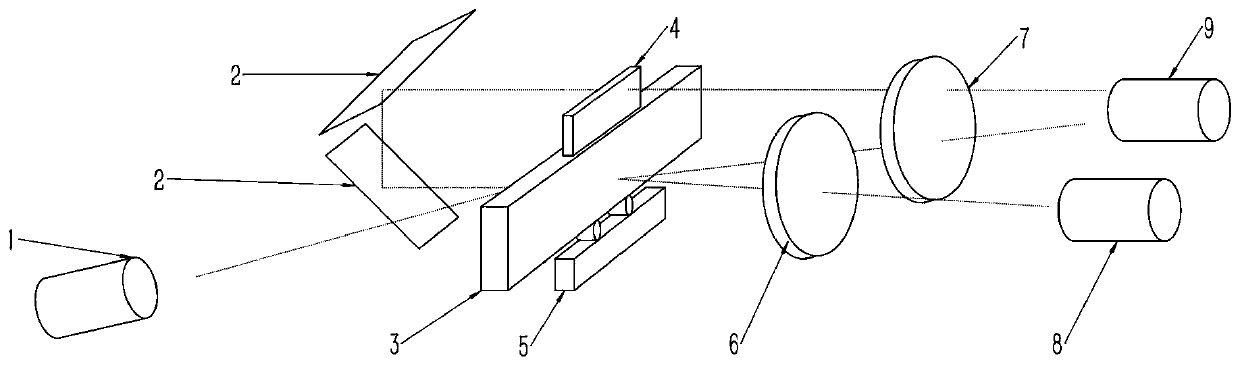

[0041] (2) A stress measurement optical path device is set, which includes a sam...

Embodiment 2

[0050] See attached figure 2 and attached image 3 , the stress measurement method that the present embodiment provides for the photoelastic method and the digital image correlation method parallel of the non-photoelastic material sample, it comprises the following steps:

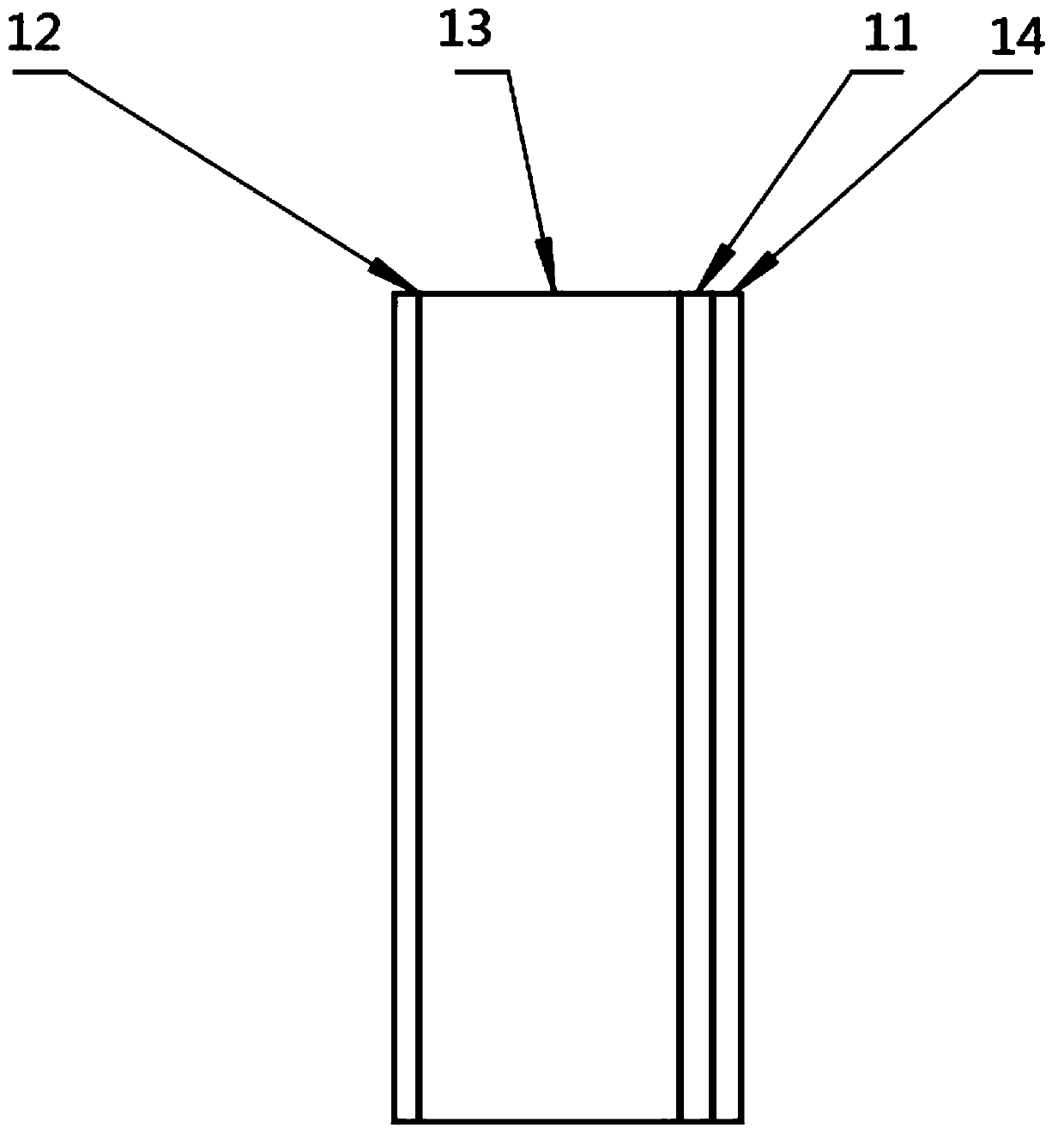

[0051] (1) Set a non-photoelastic material sample body 13 mainly made of metal or non-metallic materials, and one side surface of the non-photoelastic material sample body 13 is formed by grinding, painting or frosting, sandblasting process A speckle pattern, the other side of which is provided with a mirror surface or a plated reflective layer 11, and a photoelastic material layer 14 is also provided outside the mirror surface or reflective layer 11;

[0052] (2) A stress measurement optical path device is set, which includes a sample 3, a speckle method light source 1, a mirror 2, a supporting loading mechanism 5, a polarizer 6, an analyzer 7, a polarized light source 8 and an image acquisition unit 9, I...

Embodiment 3

[0061] See attached Figure 4 , what this embodiment provides is a stress measurement method and device in which the photoelastic method and the digital image correlation method in this embodiment are implemented on the basis of the above-mentioned embodiment 1 or embodiment 2. The difference is that:

[0062] The parallel stress measurement method of the photoelastic method and the digital image correlation method in the present embodiment also includes the following steps:

[0063] (21) An image acquisition unit 9 can be arranged on both sides of the sample 3 to collect photoelastic experiment pictures and speckle experiment pictures at the same time; the reflector in the stress measurement optical path device is removed, and the sample 3 is provided with An image acquisition unit 9 is also arranged on one side of the speckle method light source. When the speckle method light source is activated, the image acquisition unit 9 can be activated to obtain the required speckle im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com