Coupling resonance type underwater acoustic covering layer with functional gradient plate

A technology of functional gradient and coupled resonance, which is applied in the field of vibration and noise reduction materials, can solve the problems of underwater absorption and sound insulation, which are rare in the application research, difficult to meet the acoustic technical requirements of underwater vehicles, and limited applications of narrow sound absorption frequency bands, etc. problem, achieve good noise reduction effect, good noise reduction effect, and achieve the effect of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples describe the present invention in more detail.

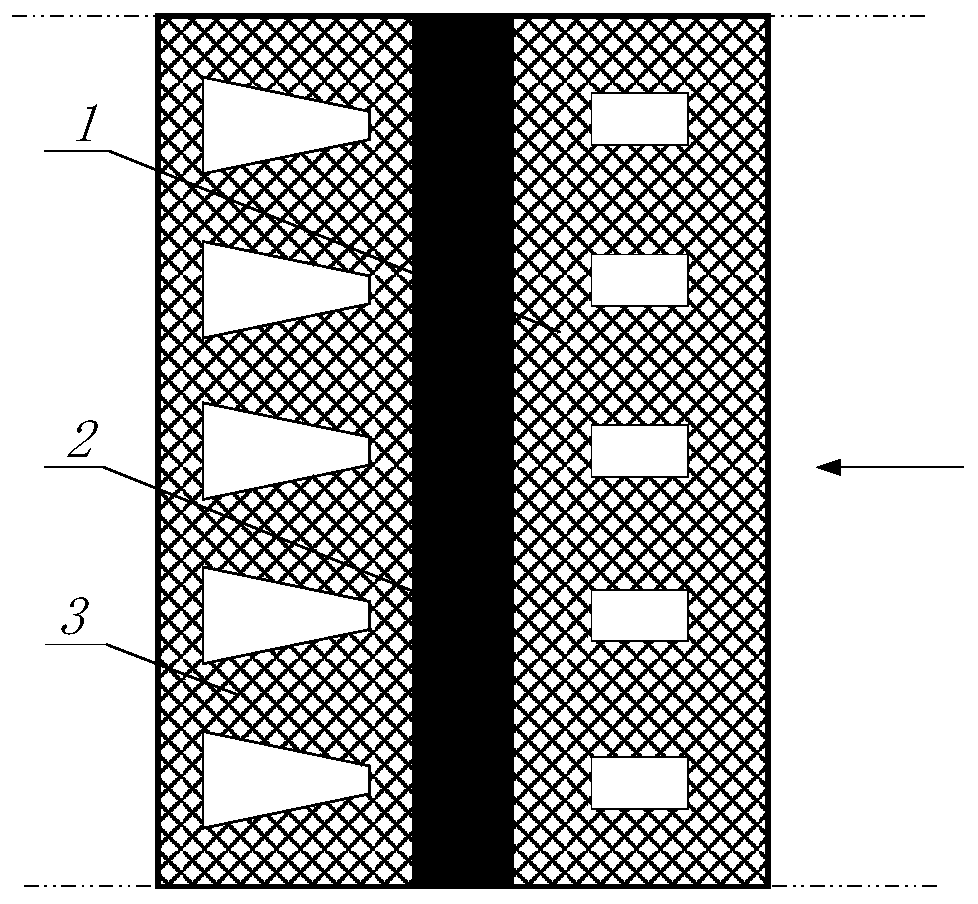

[0026] combine figure 1 , the sound wave is incident along the direction of the arrow in the figure, and the covering layer is composed of three parts: the outer covering layer 1, the functionally graded plate 2, and the inner covering layer 3 in sequence. The outer covering layer 1 and the inner covering layer 3 are laid on both sides of the functionally graded plate 2 to realize the coupling of the three. The inner covering layer 3 is pasted on the outer surface of the underwater vehicle.

[0027] The outer covering layer 1 and the inner covering layer 3 are mainly made of polyurethane sound-absorbing rubber. Both the outer cover layer 1 and the inner cover layer 3 have a cavity structure arranged periodically, and the cavity shape can be a cylinder, a circular platform, a square column, etc., wherein the cavity in the outer cover layer 1 corresponds to the cavity in the inner cover layer 3 one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com