Automatic cutting equipment for forage for aquaculture

A cutting equipment, aquaculture technology, applied in cutting equipment, agriculture, application, etc., can solve the problems of slow cutting speed, inconvenient transportation of products, easy to spoil and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

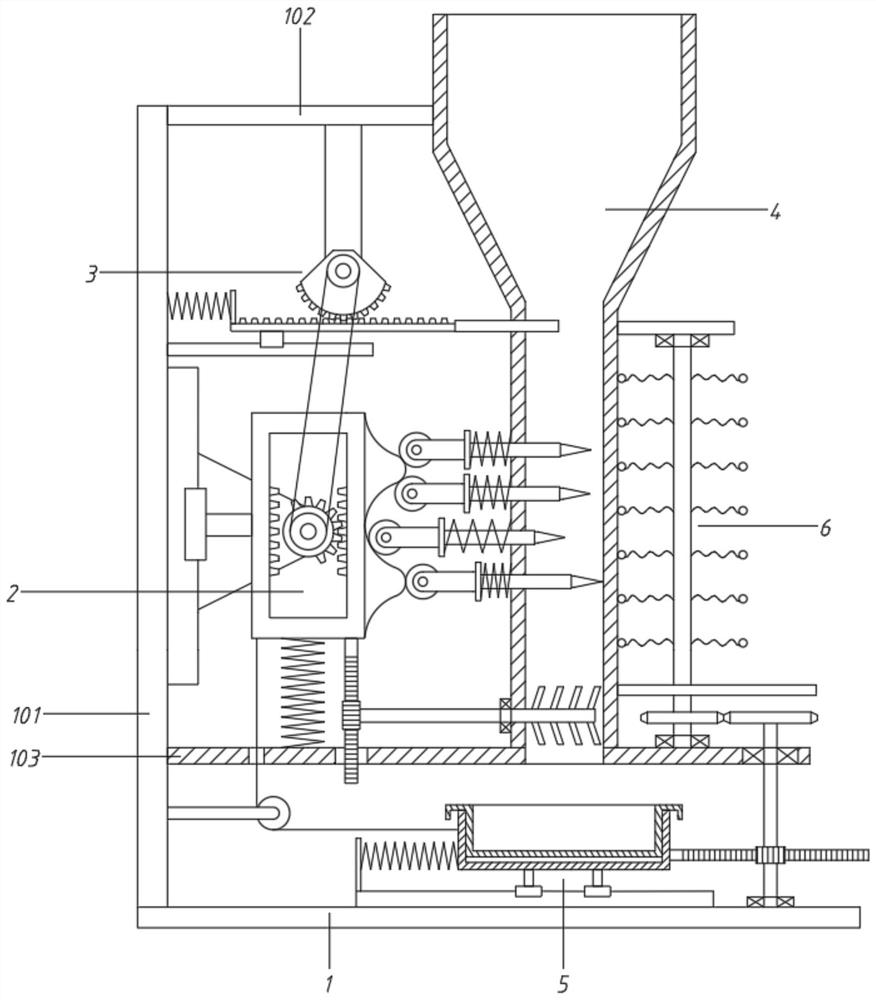

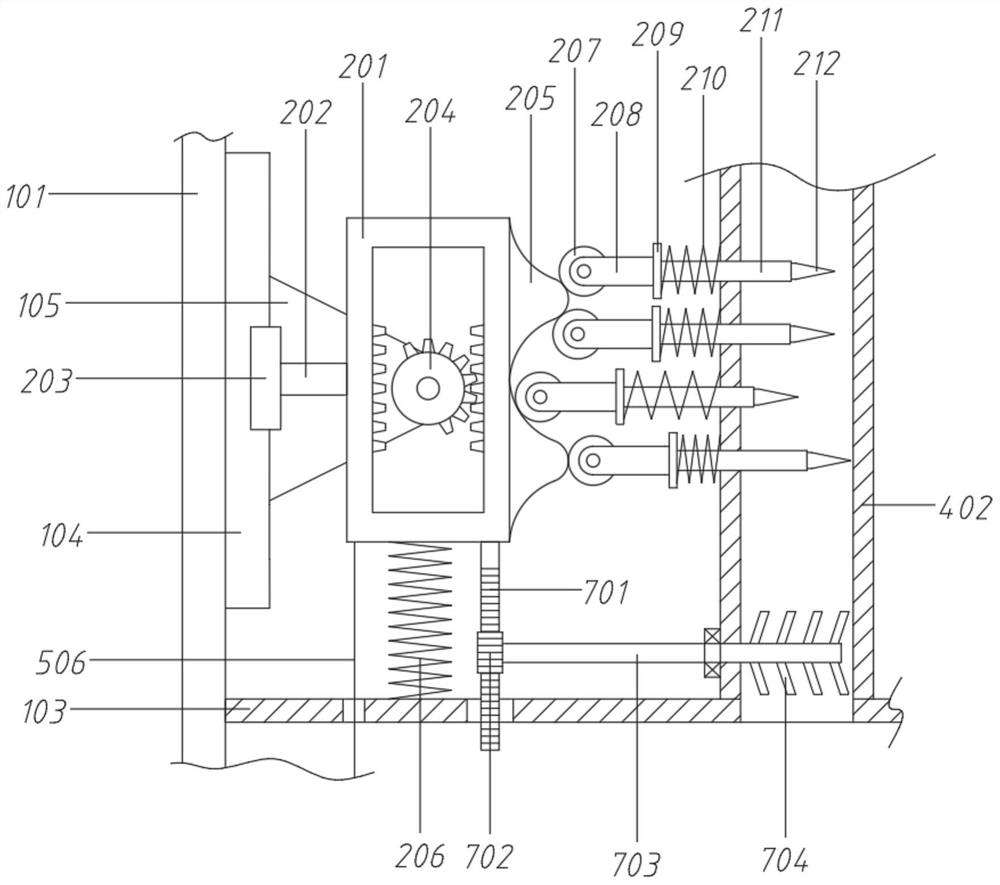

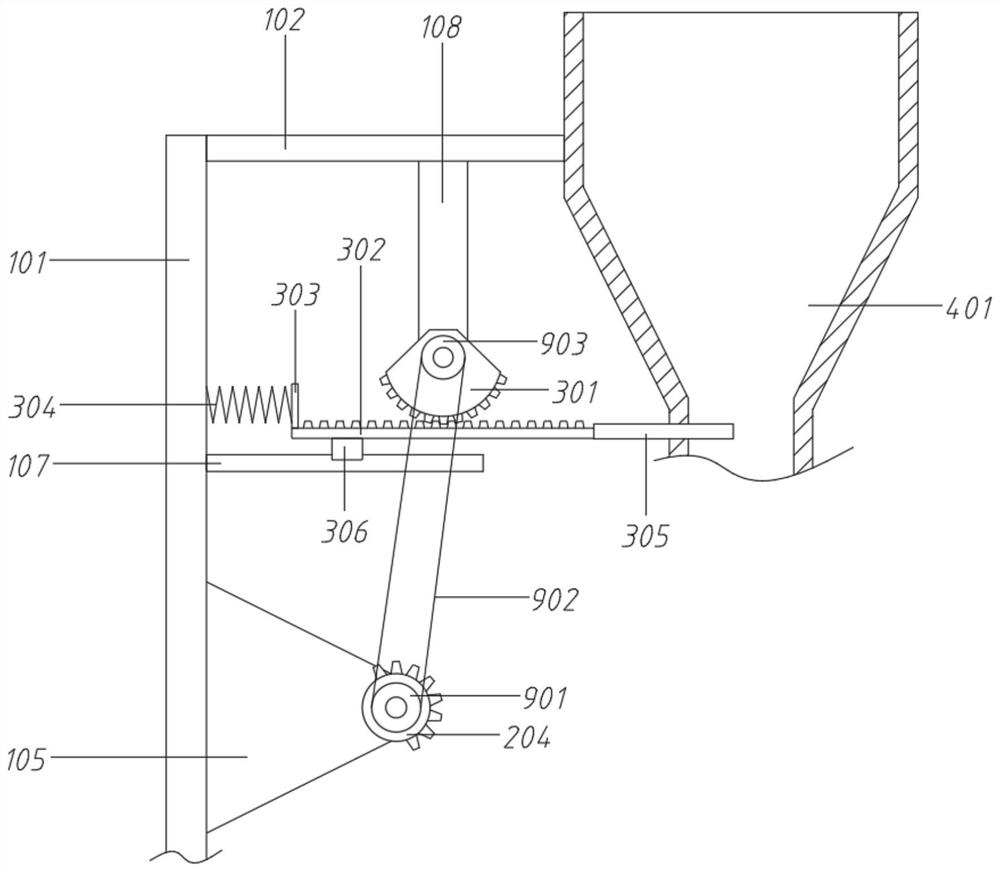

[0051] An automatic forage cutting device for aquaculture, comprising a housing 4 and a cutting assembly 2;

[0052] The housing 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and its top is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 has a feeding port;

[0053] The cutting assembly 2 is arranged on the left side of the feeding pipe 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass-cutting mechanism; Intermittent fit; incomplete gear 204 is externally connected with servo motor; rectangular frame 201 is processed with some protrusions 205 on the right side; grass cutting mechanism is set horizontally, including roller 207, wheel fork 208, pressing plate 209, guide rod 211, No. 1 spring 210 and Cutting knife 212; Roller 207 is installed on the left side of pressing plate 209 by wheel fork 208, and roller 207 is in rolling contact with protrusion 205, ...

Embodiment 2

[0056] An automatic forage cutting device for aquaculture, comprising a housing 4 and a cutting assembly 2;

[0057] The housing 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and its top is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 has a feeding port;

[0058] The cutting assembly 2 is arranged on the left side of the feeding pipe 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass-cutting mechanism; Intermittent fit; incomplete gear 204 is externally connected with servo motor; rectangular frame 201 is processed with some protrusions 205 on the right side; grass cutting mechanism is set horizontally, including roller 207, wheel fork 208, pressing plate 209, guide rod 211, No. 1 spring 210 and Cutting knife 212; Roller 207 is installed on the left side of pressing plate 209 by wheel fork 208, and roller 207 is in rolling contact with protrusion 205, ...

Embodiment 3

[0063] An automatic forage cutting device for aquaculture, comprising a housing 4 and a cutting assembly 2;

[0064] The housing 4 includes a feeding hopper 401 and a feeding pipe 402; the feeding pipe 402 is vertically arranged, and its top is connected to the bottom of the feeding hopper 401; the bottom end of the feeding pipe 402 has a feeding port;

[0065] The cutting assembly 2 is arranged on the left side of the feeding pipe 402, and includes a rectangular frame 201, an incomplete gear 204 and a grass-cutting mechanism; Intermittent fit; incomplete gear 204 is externally connected with servo motor; rectangular frame 201 is processed with some protrusions 205 on the right side; grass cutting mechanism is set horizontally, including roller 207, wheel fork 208, pressing plate 209, guide rod 211, No. 1 spring 210 and Cutting knife 212; Roller 207 is installed on the left side of pressing plate 209 by wheel fork 208, and roller 207 is in rolling contact with protrusion 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com