Self-lubricating bearing and stone crushing device applying self-lubricating bearing

A technology of self-lubricating bearings and crushing devices, applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of damage to the roller shaft, low crushing efficiency, air pollution, etc., and avoid friction damage , reduce the contact area, reduce the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

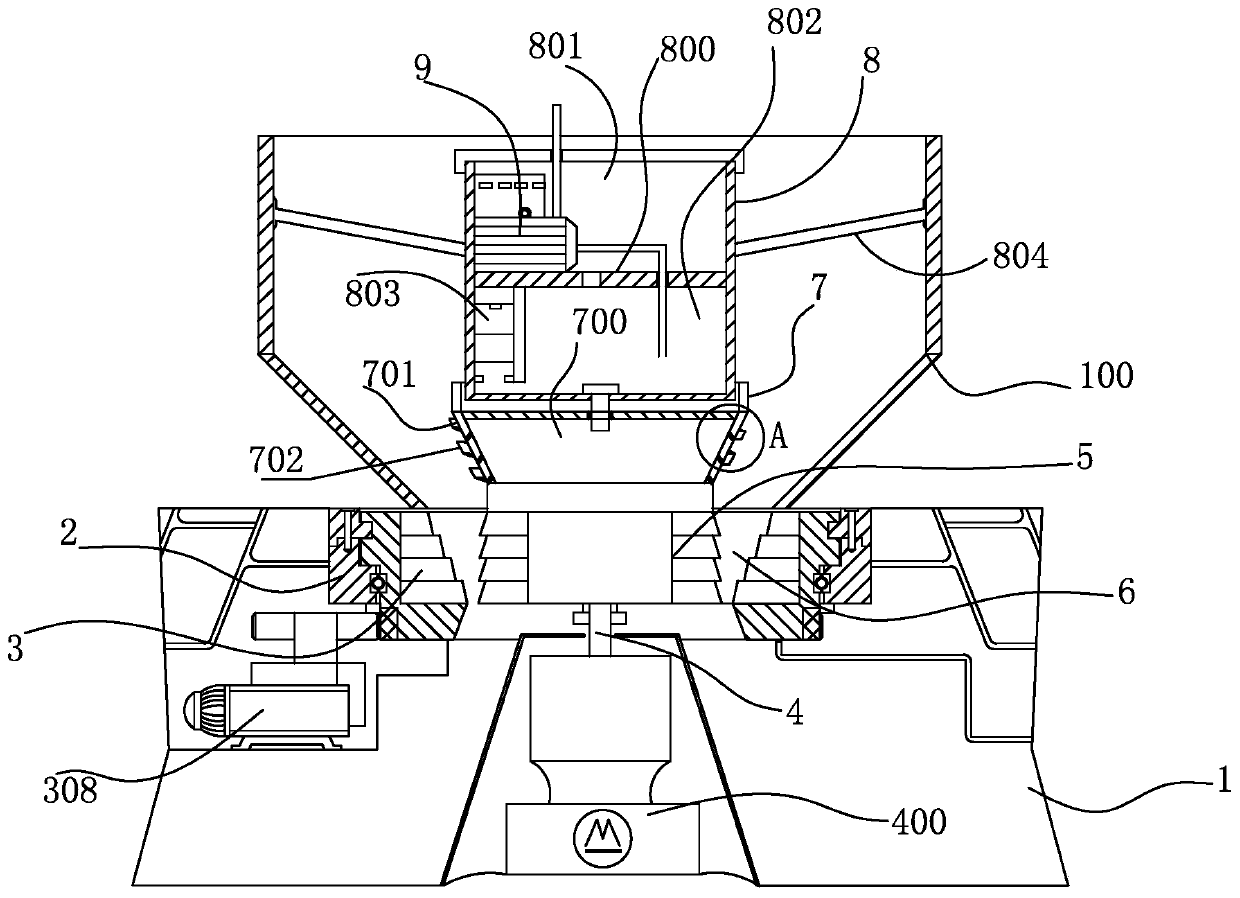

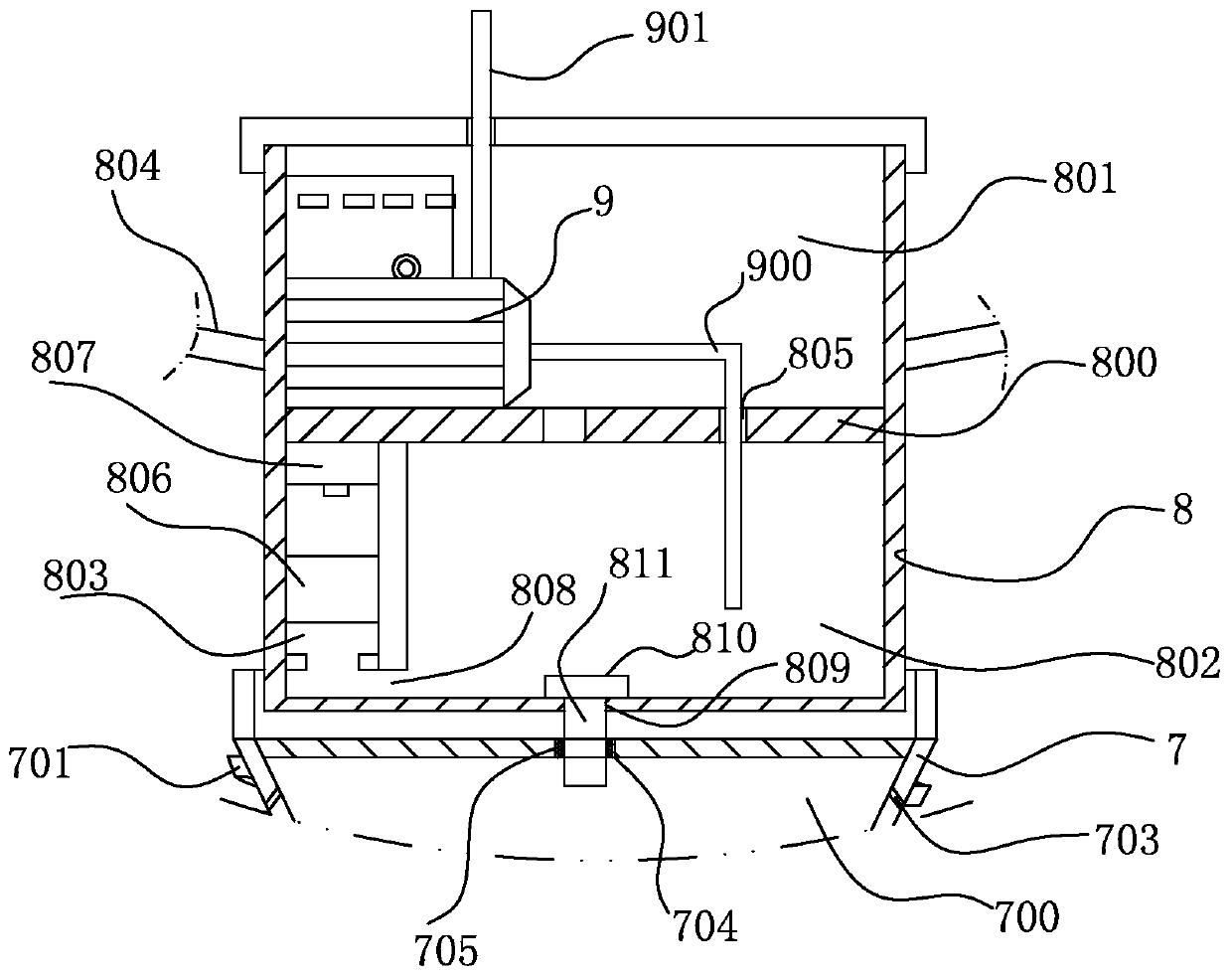

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

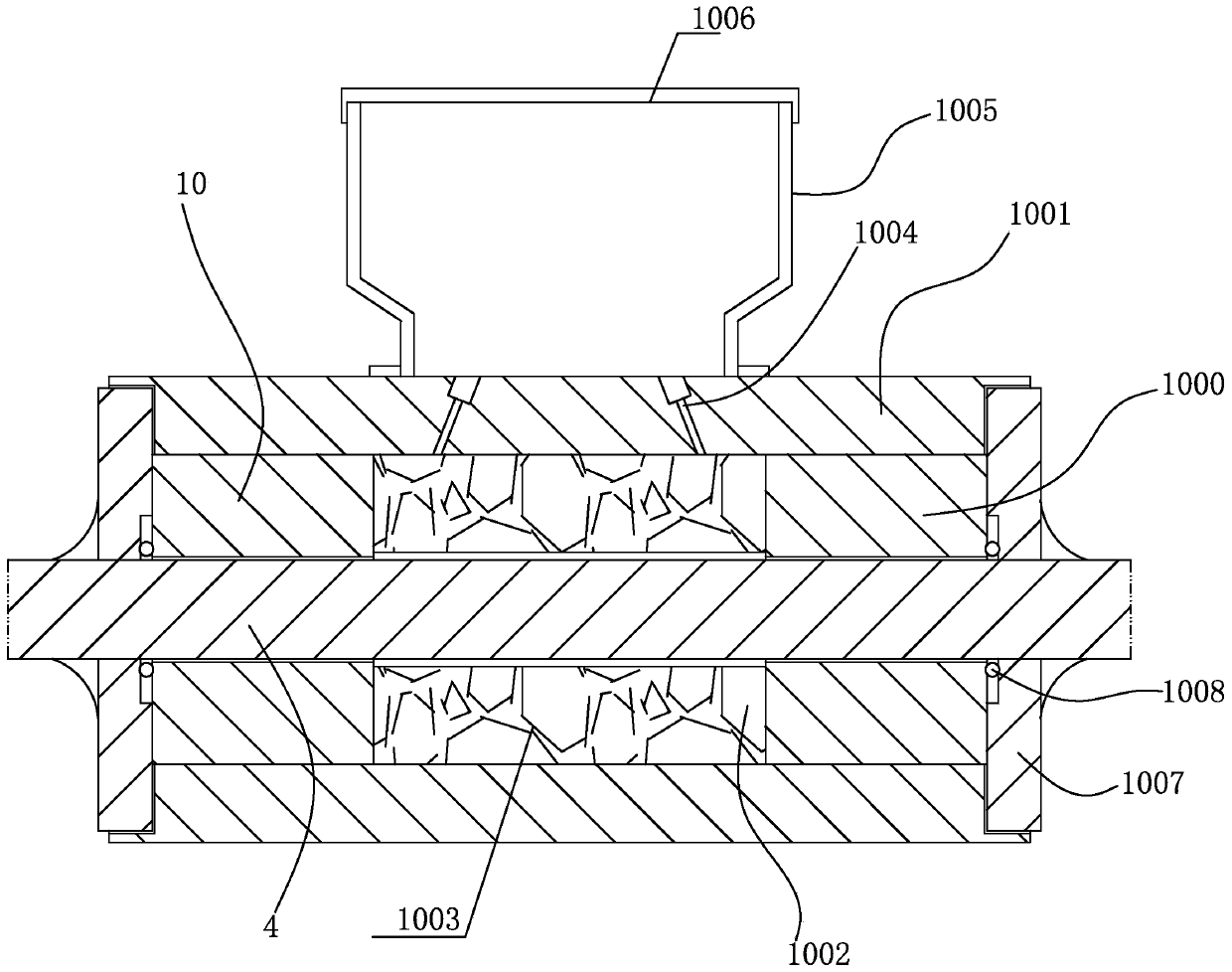

[0036] see figure 1 shown;

[0037] The present invention is a self-lubricating bearing, which includes a first shaft sleeve 10 and a second shaft sleeve 1000 sleeved on the rotating shaft 4, the inner walls of the first shaft sleeve 10 and the second shaft sleeve 1000 are connected to the outer side of the rotating shaft 4 Wall gap fit; the outer side of the first shaft sleeve 10 and the second shaft sleeve 1000 is provided with a base 1001, and the inner wall of the base 1001 is sealed with the outer side wall of the first shaft sleeve 10 and the second shaft sleeve 1000; An annular cavity 1002 is provided between the first bushing 10 and the second bushing 1000, and an oil storage block 1003 made of flexible microporous material is arranged inside the annular cavity 1002, and the oil storage block 1003 is 1003 is attached to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com