Scrap iron removal device for wire cutting machine cooling liquid

A cleaning device, wire cutting machine technology, applied in attachments, electric processing equipment, metal processing equipment and other directions, can solve the problems of normal circulation of cooling liquid, iron filings doping, inconvenient cooling liquid recycling and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

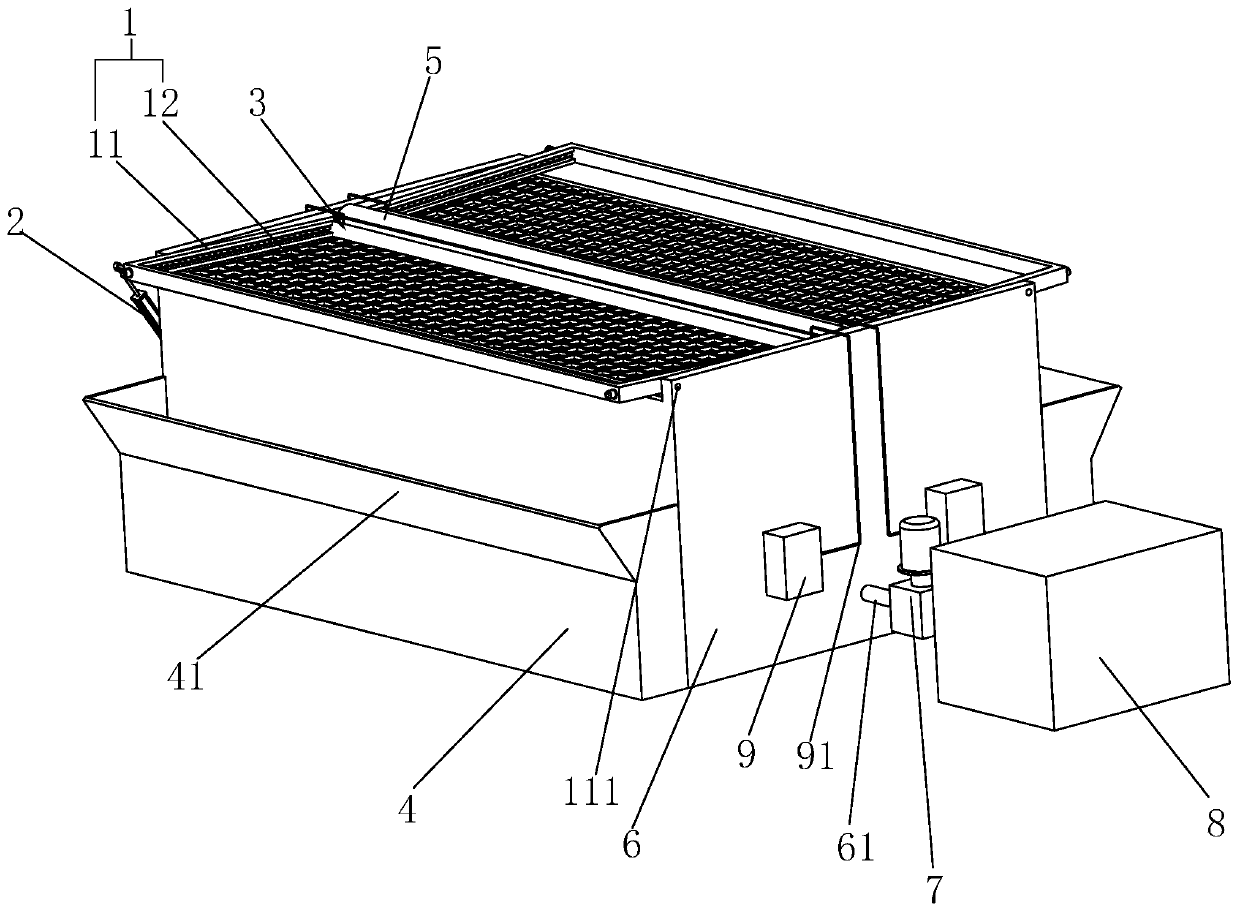

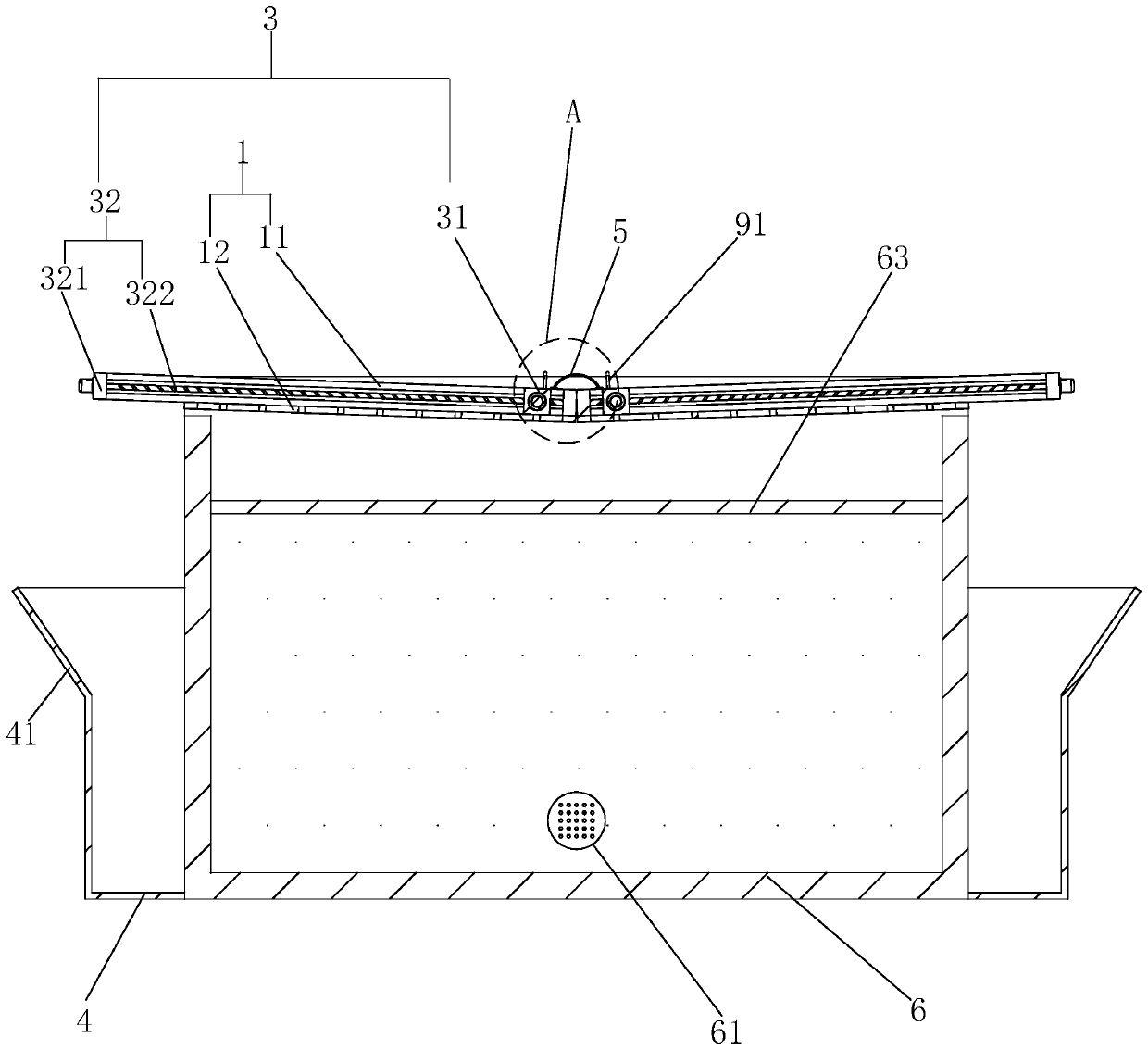

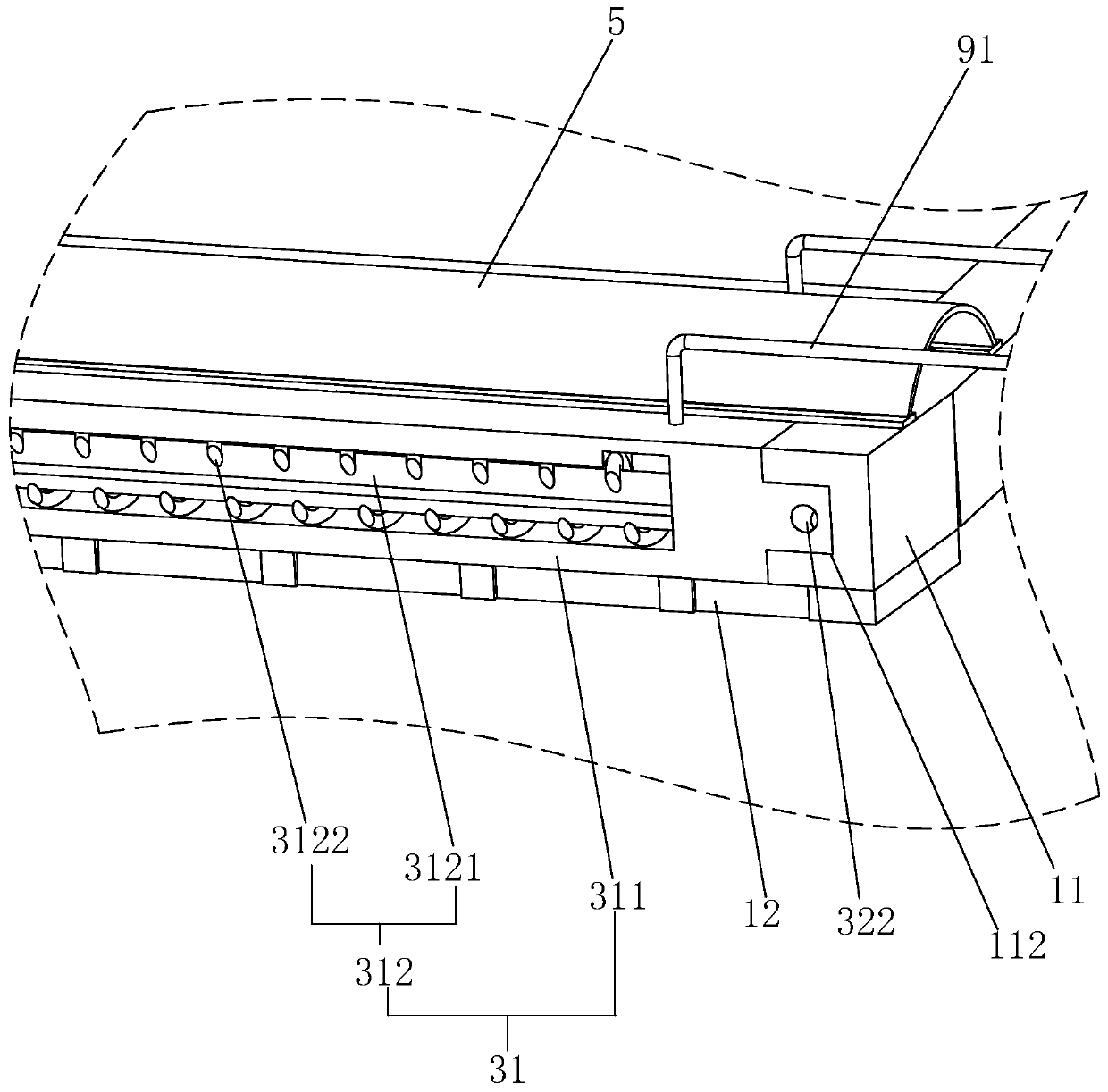

[0036] Such as figure 1As shown, the present invention introduces a chip cleaning device for wire cutting machine coolant, including a filter device 1, a driver, a cleaning device 3 and a collection box 4. The wire cutting machine includes a coolant tank 6 and a water adding mechanism 8, and the cooling The liquid tank 6 is connected with a water pump 7, and the water pump 7 is connected between the coolant tank 6 and the water adding mechanism 8, and then combined with figure 2 As shown, the upper surface of the coolant tank 6 is open, and the filter device 1 includes two overturn frames 11, which are symmetrically arranged on two opposite edges of the upper surface of the coolant tank 6, and the two overturn frames 11 are It is V-shaped and covers the upper surface of the coolant tank 6, and the V-shaped opening is upward, and two rotating rods 111 are respectively fixedly connected on the two opposite outer walls of the flip frame 11, and one of the two rotating rods 111 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com