A steel structure truss welding process

A welding process and steel structure technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor cost, steel position adjustment error, low work efficiency, etc., saving operation steps and avoiding the accumulation of errors , the effect of saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

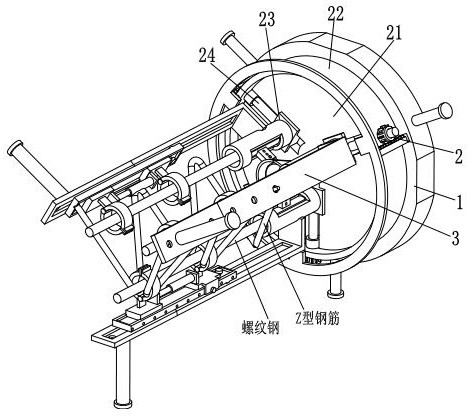

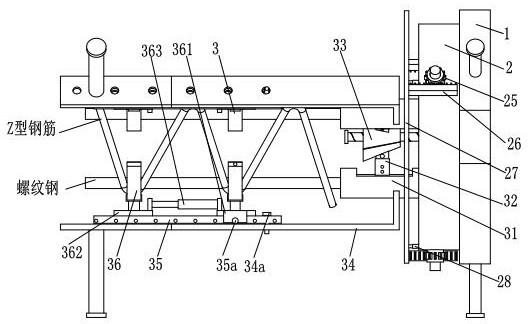

[0038] Such as Figure 1 to Figure 8As shown, a steel structure truss welding process mainly includes the following steps:

[0039] S1. Arrangement and positioning of the rebars: the staff puts the three rebars into the corresponding positions of the welding positioning fixture one by one, and locks the position of the rebars;

[0040] S2. Construction of Z-shaped steel bar: Lap the Z-shaped steel bar and rebar, and temporarily fix the position of the Z-shaped steel bar by welding positioning fixture;

[0041] S3. Point-by-point welding: use welding equipment to weld the Z-shaped steel bar and the rebar contact point by point to make a steel structure truss;

[0042] S4. Post-welding treatment: use sandpaper to grind the welded part, remove weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com