A hoisting and flipping method for square pyramid equipment

A kind of equipment and cone technology, applied in the field of hoisting and turning, can solve problems such as the difficulty of hoisting and turning, achieve the effect of improving the efficiency of machinery use, improving construction safety, and avoiding high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

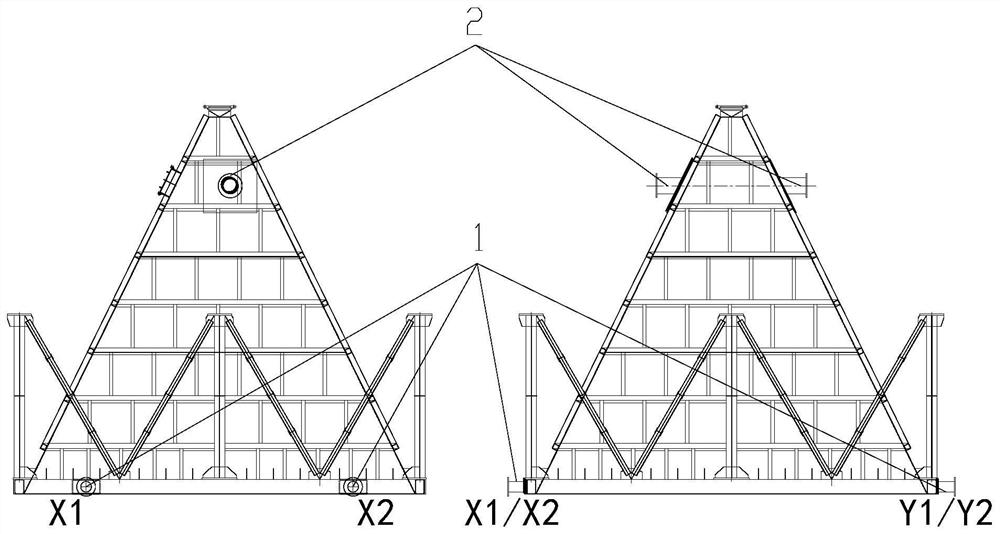

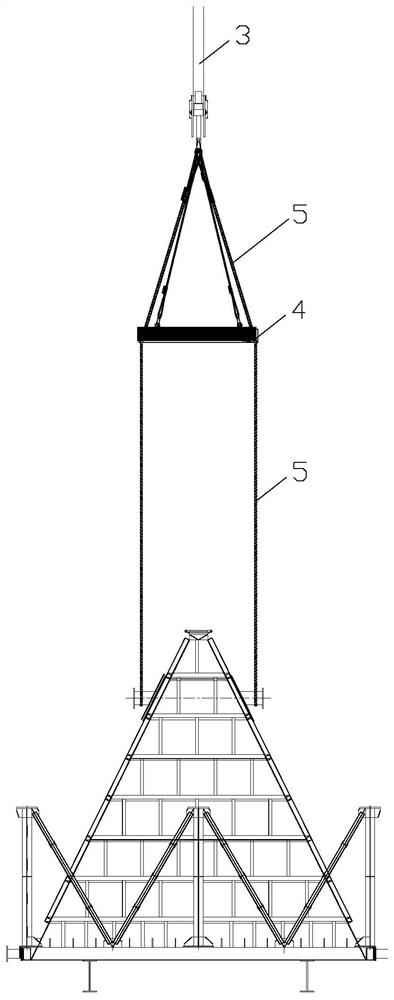

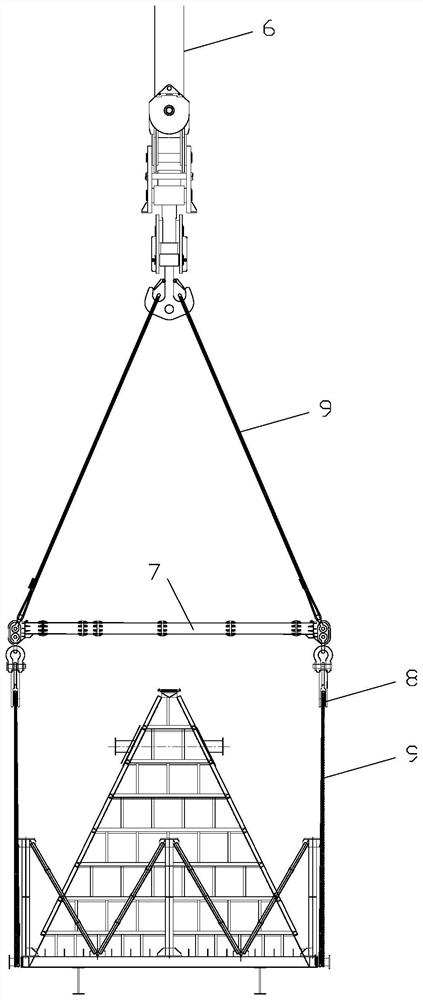

[0034] This embodiment provides a hoisting and turning method for square pyramid-type equipment, by setting four-pipe shaft-type main lifting lugs 1 at the bottom of square pyramid-type equipment, and setting eccentric tube-shaft type sliding tail lifting lugs 2 on the upper part , the tail-sliding crane 3 is used to configure the tail-slung balance beam 4 and the tail-sliding crane wire rope 5 to lift the square pyramid equipment, and the rear pyramid equipment is in a tilted state after lifting, and the other main crane 6 is equipped with the main suspension balance beam 7, The rigging system composed of the fixed pulley 8 and the main hoisting wire rope 9 is tied to the four main lifting lugs 1 symmetrically distributed under the square pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com