Acrylamide-alginate sand stabilization and water retention agent and preparation method thereof

A technology of acrylamide and alginic acid, which is applied in chemical instruments and methods, other chemical processes, applications, etc., can solve the problems of high implementation cost, large manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

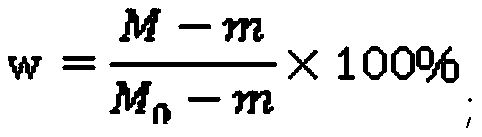

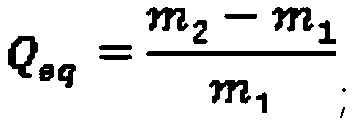

Method used

Image

Examples

Embodiment 1

[0026] A kind of acrylamide-alginate type sand-fixing and water-retaining agent, its preparation comprises the steps:

[0027] Step 1. Mix 25g sodium alginate, 5g konjac glucomannan and water, heat up and stir until completely dissolved to obtain the first reaction feed liquid; mix 70g acrylamide and water, heat up and stir until completely dissolved to obtain the second reaction Liquid;

[0028] Step 2: Add the second reaction feed liquid in the first reaction feed liquid, stir and mix evenly and then add ammonium persulfate thereto (in terms of the volume of every liter of reaction feed liquid, its addition is 3.5g), stir until the initiator is completely After dissolving, add a cross-linking agent (the amount added is 2 g per liter of reaction feed liquid volume) to obtain a reaction feed liquid, react the reaction feed liquid at 25°C for 6 hours under stirring, and then add iron oxide green therein (The amount of the coloring agent added is 10 g per liter of reaction feed...

Embodiment 2

[0030] A kind of acrylamide-alginate type sand-fixing and water-retaining agent, its preparation comprises the steps:

[0031] Step 1. Mix 13g of sodium alginate, 2g of konjac glucomannan and water, heat up and stir until completely dissolved to obtain the first reaction feed liquid; mix 85g of acrylamide and water, heat up and stir until completely dissolved to obtain the second reaction Liquid;

[0032] Step 2: Add the second reaction feed liquid in the first reaction feed liquid, stir and mix evenly, then add ammonium persulfate (in terms of the volume of every liter of reaction feed liquid, its addition is 3.8g), stir until the initiator is completely After dissolving, add a cross-linking agent (2.7 g per liter of reaction feed liquid volume) to obtain a reaction feed liquid, react the reaction feed liquid at 28°C for 6.5 hours under stirring, and then add an oxidizing agent to it. Iron green (the amount of coloring agent added per liter of reaction feed liquid volume is ...

Embodiment 3

[0034] A kind of acrylamide-alginate type sand-fixing and water-retaining agent, its preparation comprises the steps:

[0035] Step 1. Mix 12g of sodium alginate, 5g of konjac glucomannan and water, heat up and stir until completely dissolved to obtain the first reaction feed liquid; mix 83g of acrylamide and water, heat up and stir until completely dissolved to obtain the second reaction Liquid;

[0036] Step 2: Add the second reaction feed liquid in the first reaction feed liquid, stir and mix evenly, then add ammonium persulfate (in terms of the volume of every liter of reaction feed liquid, its addition is 3.8g), stir until the initiator is completely After dissolving, add a cross-linking agent (2.7 g per liter of reaction feed liquid volume) to obtain a reaction feed liquid, react the reaction feed liquid at 28°C for 6.5 hours under stirring, and then add an oxidizing agent to it. Iron green (the amount of coloring agent added per liter of reaction feed liquid volume is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com