A kind of coated controlled-release fertilizer and preparation method thereof

A technology of coated controlled-release fertilizer and binder, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of reducing fertilizer utilization rate, not seeing silica sand, waste of ordinary compound slow-release fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0036] Example 1-6: Coated controlled-release fertilizer

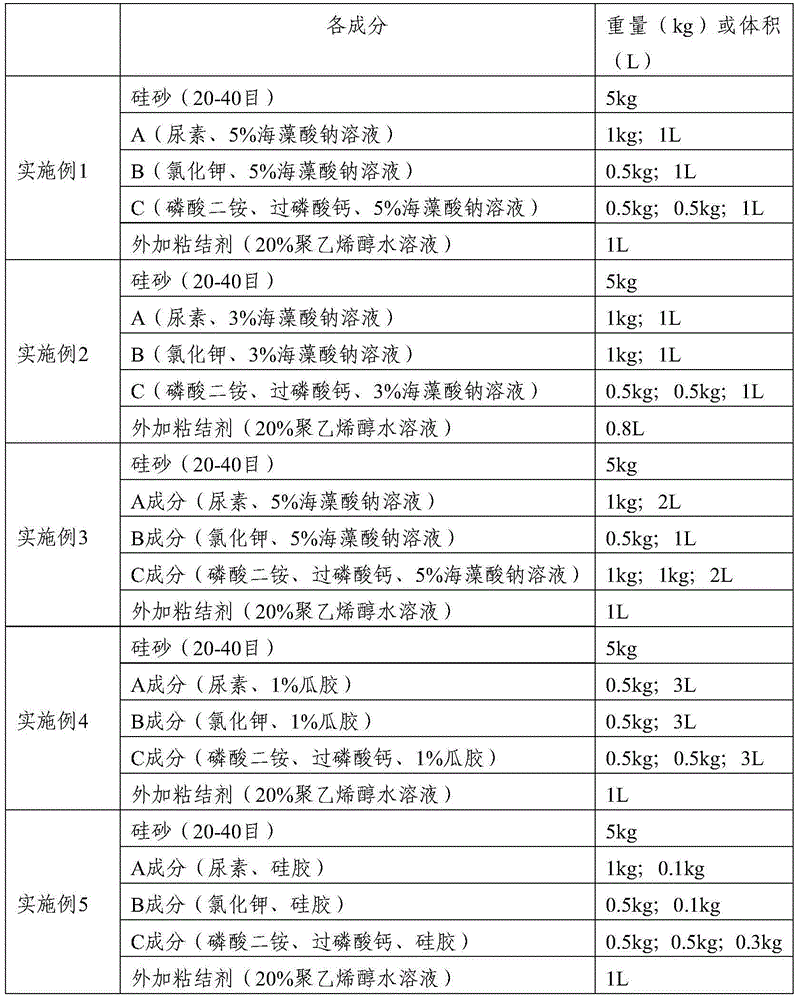

[0037] 1. Raw materials: see Table 1

[0038] Table 1: Raw material ratio of each embodiment

[0039]

[0040] 2. Preparation method:

[0041] method one:

[0042] 1) Mix the ingredients A, B, and C separately, and set aside;

[0043] 2) Put the silica sand and A into the sand mixer, and after mixing the sand for 2 minutes, add 0.3L of 20% polyvinyl alcohol solution (equivalent to 30% of the added binder);

[0044] 3) Add B to the sand mixer in step 2) and mix sand for 2 minutes, and add 0.3L of 20% polyvinyl alcohol solution (equivalent to 30% of the added binder);

[0045] 4) Add component C to the sand mixer in step 3) and mix sand for 2 minutes, add 0.4L of 20% polyvinyl alcohol solution (equivalent to 40% of the added binder), take it out, and dry it at 30°C.

[0046] Method Two:

[0047] 1) Mix the ingredients A, B, and C separately, and set aside;

[0048] 2) Put the silica sand and component B into th...

experiment example 1

[0069] Experimental example 1: detection of nutrient release speed

[0070] 1. Test the release rate of the coated controlled-release fertilizer provided in Examples 1-5 and Comparative Example 1 and Comparative Example 2 (Example 1 of CN200410050221.6 (publication number is CN1587235A), among them, Examples 1-5 The preparation methods are method 1, method 2, method 3, method 4 and method 1 in sequence, and the specific detection methods are:

[0071] Dissolve 100 grams of slow-release fertilizer in 500ml of water, measure the concentration of each nutrient in the water every other week, calculate the dissolved quality of each nutrient, and the mass ratio (percentage) of each nutrient that should be contained in 100 grams of slow-release fertilizer, of which nitrogen fertilizer adopts Kai The nitrogen determination method was used for detection, the phosphate fertilizer was detected by the phosphorus molybdenum blue colorimetric method, and the potassium fertilizer was detecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com