A constant temperature incubation device suitable for experimental research on complex crystals

A technology of experimental research and cultivation equipment, which is applied in the field of constant temperature cultivation equipment for complex crystal experimental research, which can solve the problems of separate heating of crystallizers and the inability to study the growth of complex crystals, and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

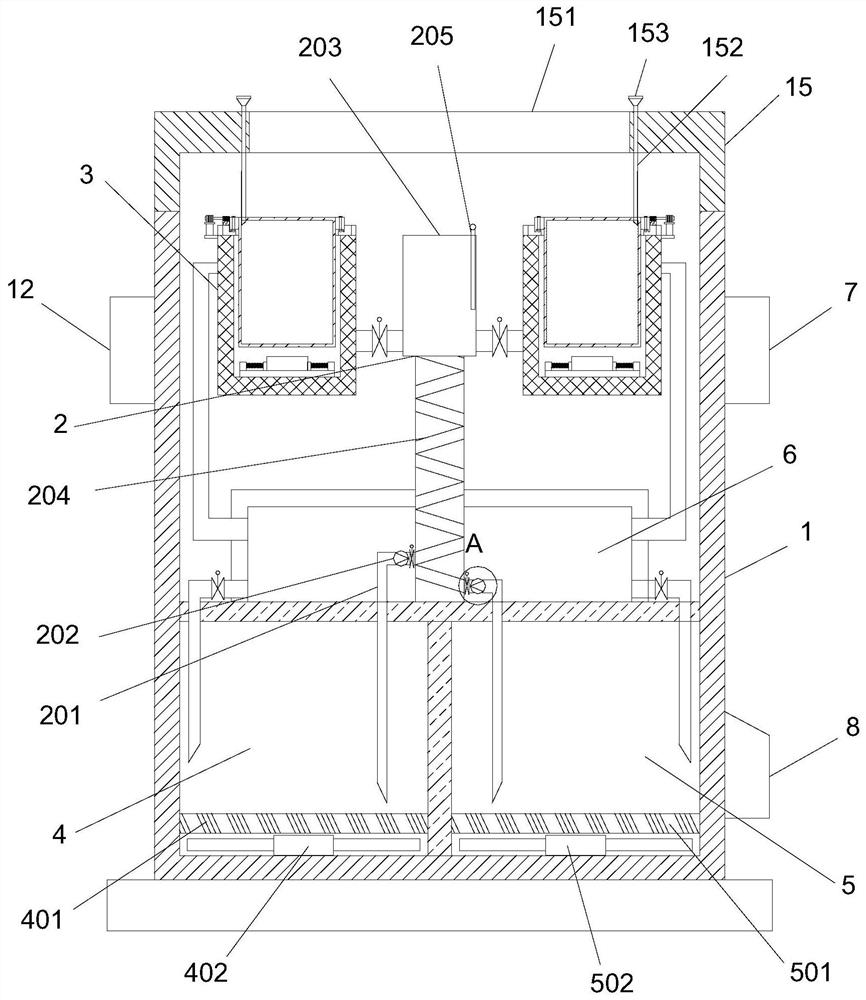

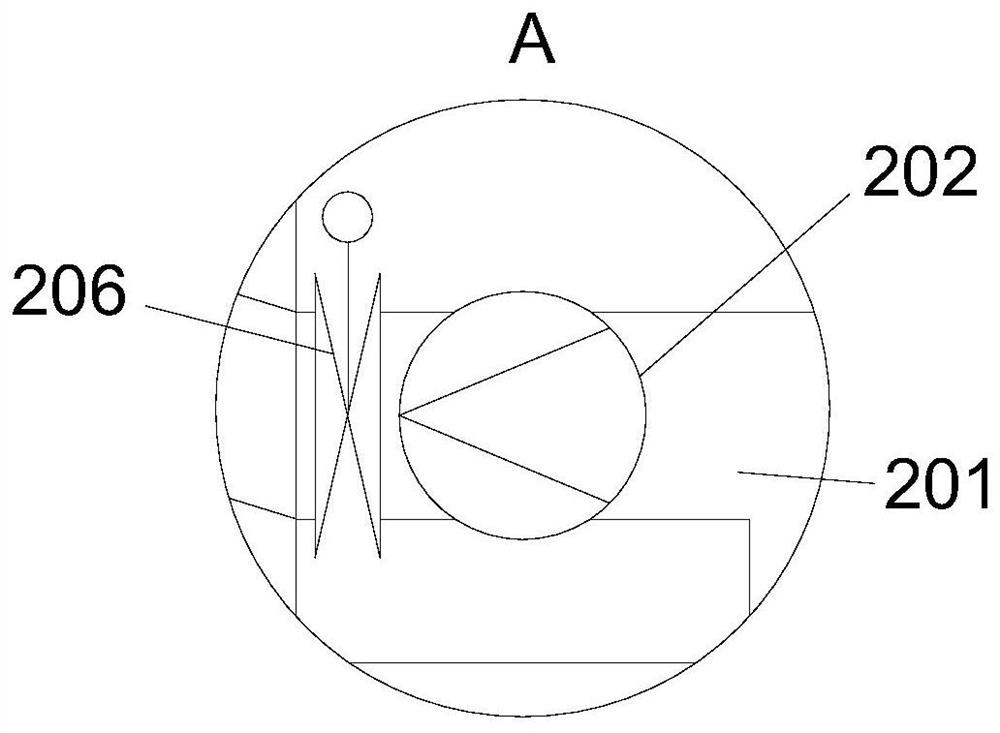

[0031] see Figure 1-3 As shown, a constant temperature cultivation device suitable for the experimental research of complex crystals provided by the embodiment of the present invention includes a cultivation box 1 and a cultivation chamber 3, and the cultivation chamber 1 is provided with a constant temperature chamber 2 for adjusting the temperature of the cultivation chamber 3 The two sides of the bottom of the thermostatic chamber 2 are respectively connected to the heating chamber 4 and the freezing chamber 5 through the connecting pipe 201. Both the heating chamber and the freezing chamber are filled with a heat transfer liquid, and the temperature of the heat transfer liquid is controlled by the heating device or the refrigeration device of the bottom plate respectively. adjust. Each connecting pipe 201 is provided with a liquid suction pump 202, through which the liquid in the corresponding heating chamber and the freezing chamber can be pumped to adjust the temperatur...

Embodiment 2

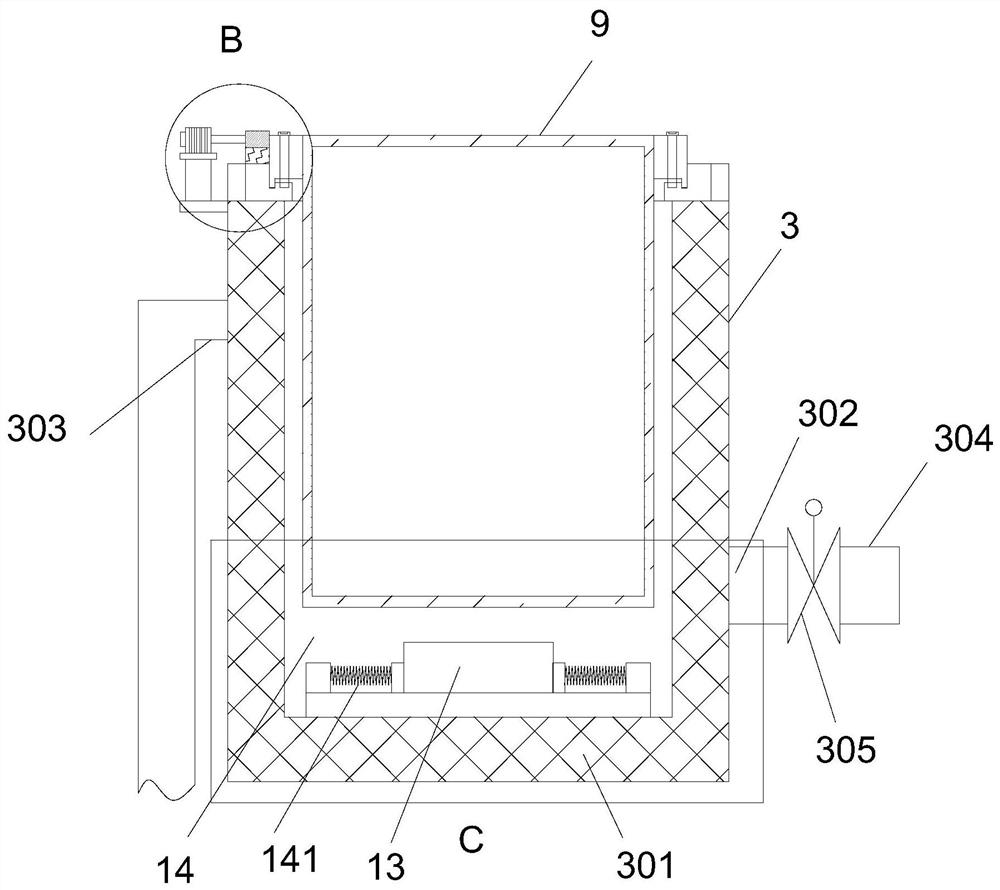

[0039] see Figure 3-5 As shown, the difference from the above embodiment is that, in order to facilitate the study of the influence of different rotation speeds on the crystal growth of complexes, each incubation chamber 3 is provided with a crystallizer 9 that is rotatably connected to the side wall of the incubation chamber 3 , the top outer wall of each crystallizer 9 is rotatably connected to the inner wall of the corresponding cultivation chamber 3 through a bearing 10, and each bearing 10 is provided with a circle of the first ring composed of several gear teeth near the top of the inner ring of the crystallizer 9 corresponding to it. A gear 101, the top side of each incubation chamber 3 is provided with a motor 11, and the output shaft of each motor 11 is connected with a second gear 111, and each second gear 111 is installed on the corresponding first gear 101 and meshes with the teeth of the first gear 101. The output shaft on the motor is fixedly connected with the...

Embodiment 3

[0044] see image 3 and Figure 5 As shown, the difference from the above-mentioned embodiment is that each crystallizer 9 is provided with a scale on the inner wall, which facilitates the quantitative addition of the liquid required for the growth of complex crystals. In order to facilitate the study of the influence of the magnetism of the magnet on the crystal growth of the complex, the bottom of each incubation chamber 3 is provided with a permanent magnet 13, and each incubation chamber 3 and its corresponding crystallizer 9 are jointly enclosed to form a space for installing the permanent magnet 13. The installation chamber 14 is provided with an elastic clip 141 for clamping the permanent magnet 13 inside the installation chamber 14, so that the permanent magnet can be stably mounted on the bottom of the installation chamber.

[0045] In this embodiment, a permanent magnet is installed at the bottom of each incubation chamber, which can be used to study the influence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com