Control method for preventing vehicle flameout caused by signal loss of crankshaft position sensor

A sensor signal and crankshaft position technology, applied in the field of automobile manufacturing, can solve problems affecting driving safety, reliability deviation of derivative functions, and insufficient resolution of cam signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the drawings and embodiments:

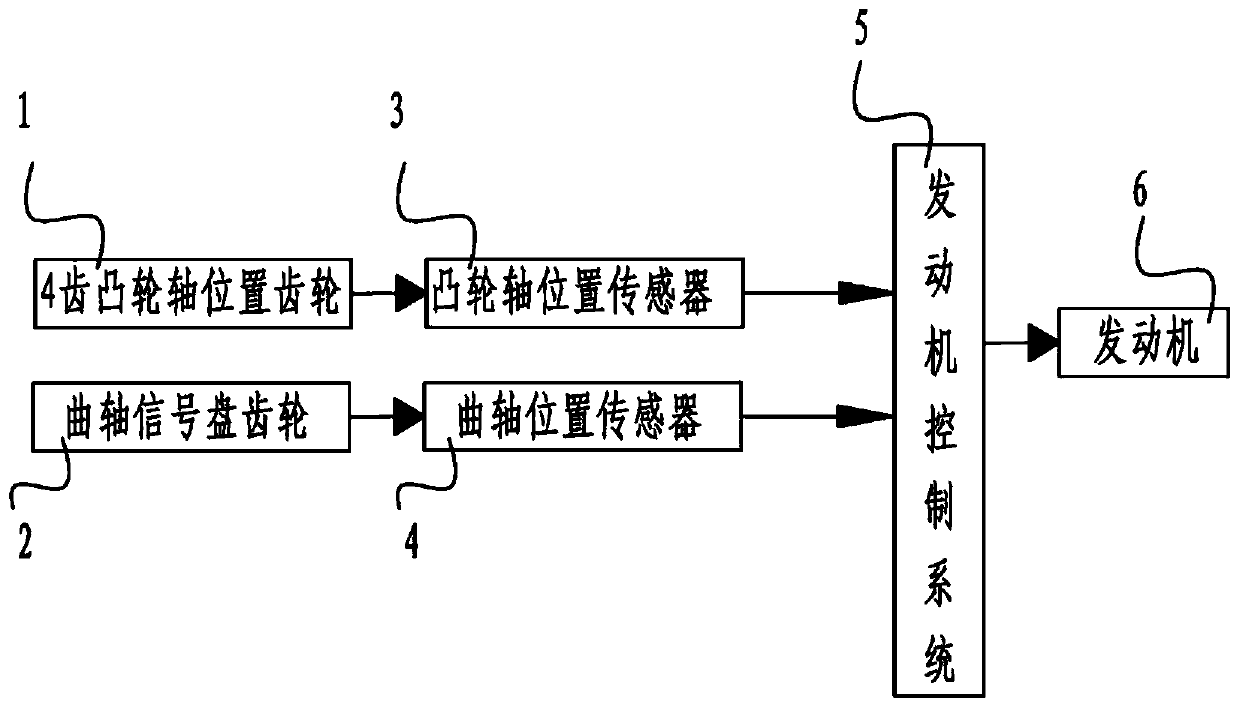

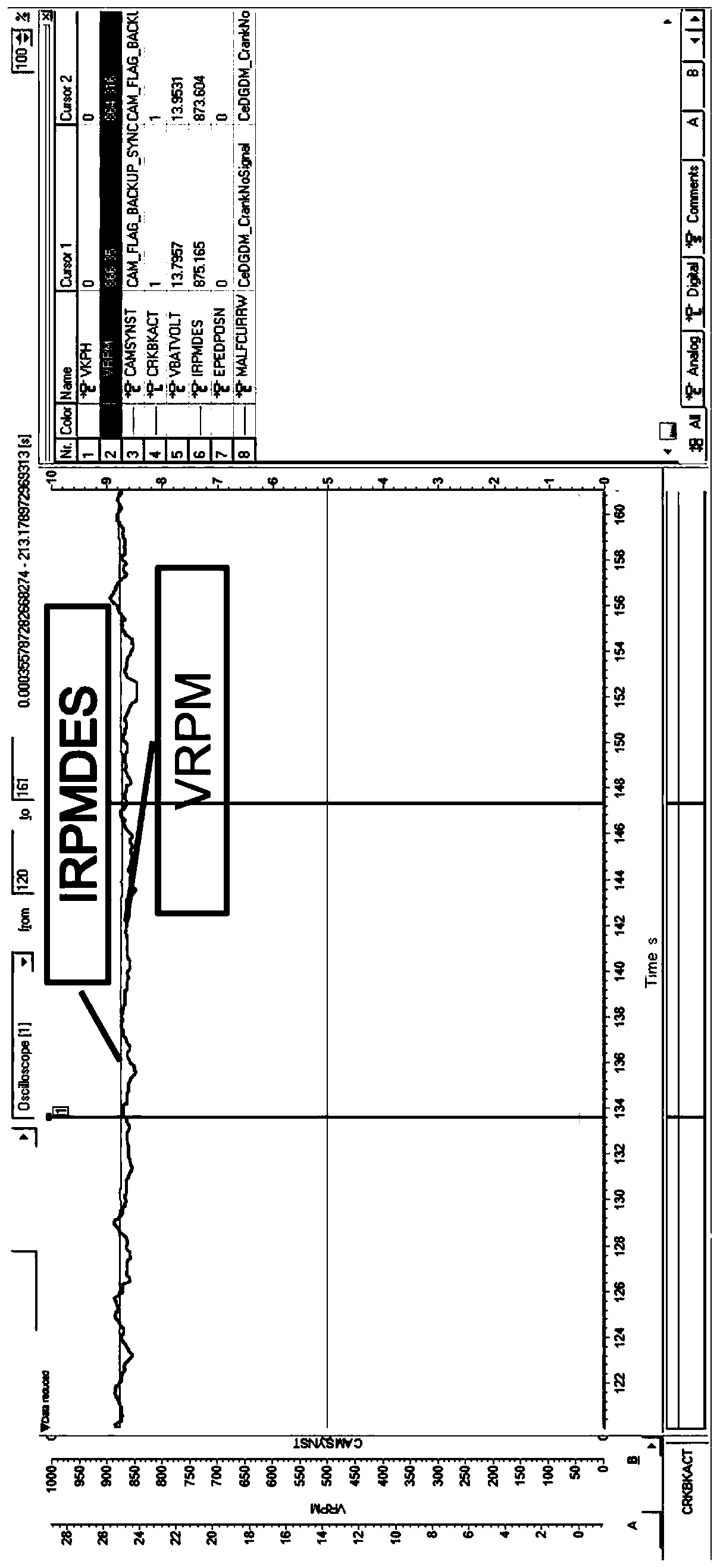

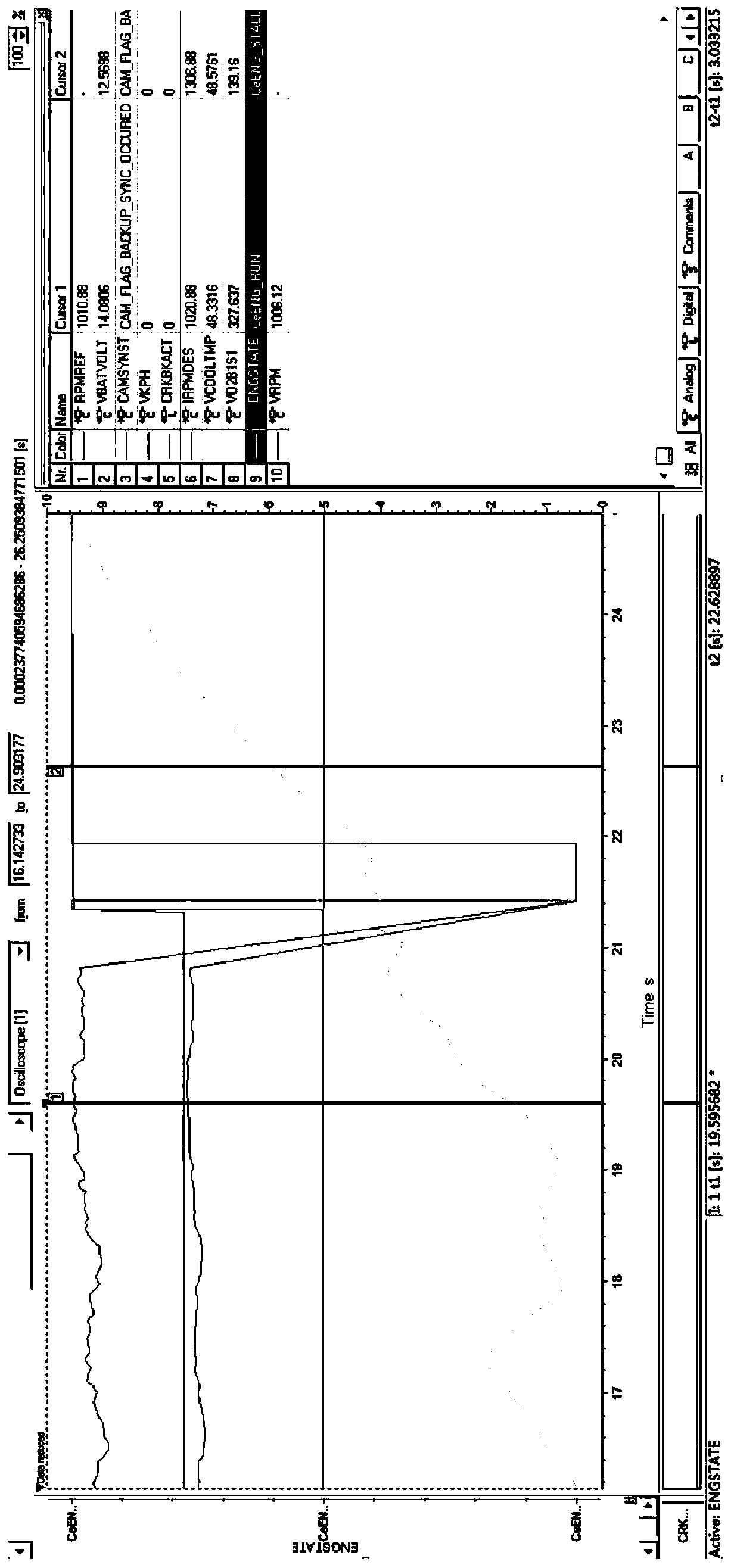

[0020] figure 1 The shown control method for preventing the engine crankshaft position sensor signal from being lost and causing the vehicle to stall is implemented by a crankshaft position control device, which includes a four-tooth camshaft position signal gear 1 and a crankshaft signal plate gear 2, and a four-tooth camshaft position signal gear 1 and crankshaft signal plate gear 2 trigger camshaft position sensor 3 and crankshaft position sensor 4, respectively. Camshaft position sensor 3 and crankshaft position sensor 4 respectively transmit the crankshaft position signal and camshaft position signal to the engine control system 5. Engine control system 5 Control the engine ignition and fuel injection based on the corresponding relationship between the crankshaft position signal and the camshaft position signal; the realization method is: 1) When the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com